Conical optical fiber flow velocity sensor based on femtosecond laser inscribing FBG

A flow velocity sensor, femtosecond laser technology, applied in fluid velocity measurement, instrument, velocity/acceleration/shock measurement, etc., can solve the problems of unsatisfactory micro-probe design, complex structure, narrow dynamic sensing range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

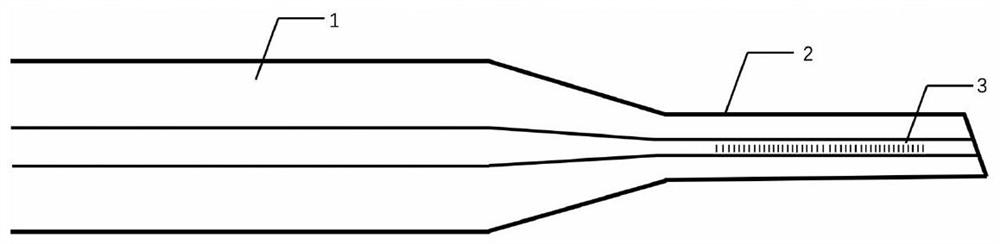

[0013] figure 1 It is a schematic diagram of the structure of the sensor head of the present invention. A tapered single-mode fiber is obtained by stretching an ordinary single-mode fiber through discharge, wherein the diameter of the cone waist is 9-11 μm, the length of the cone waist is 5-10 mm, and the inclination angle of the end of the cone waist is 7.5 °-8.5°. The FBG is written on the cone waist by a point-by-point method with a femtosecond laser, the length is 2-5mm, and the Bragg wavelength is 1450-1560nm.

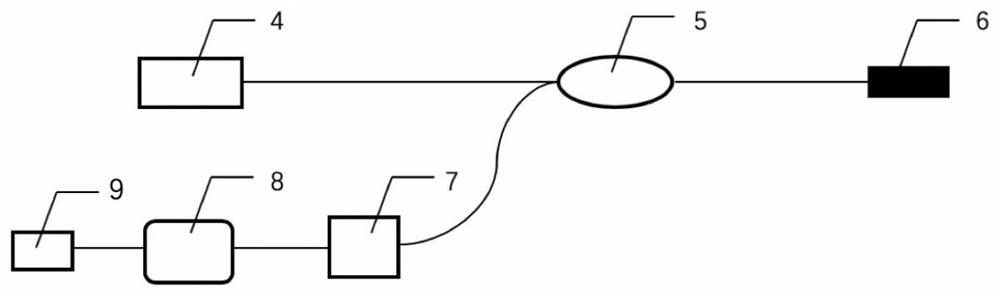

[0014] figure 2 Shown is the implementation application system schematic diagram of the present invention, comprises single-wavelength laser, circulator, optical fiber sensing head, photodetector, A / D data acquisition unit and microprocessor, laser, optical fiber sensing head, photoelectric The detectors are respectively connected to the three ports of the circulator, and the photodetectors convert the collected optical signals into electrical signals, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com