Recovery enthalpy calibration test piece and wind tunnel thermal assessment method

A test method and test piece technology, applied in the field of thermal assessment experiments, can solve the problems of high price, waste of time and funds, long processing cycle, etc., and achieve the effects of long processing cycle, simple manufacturing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

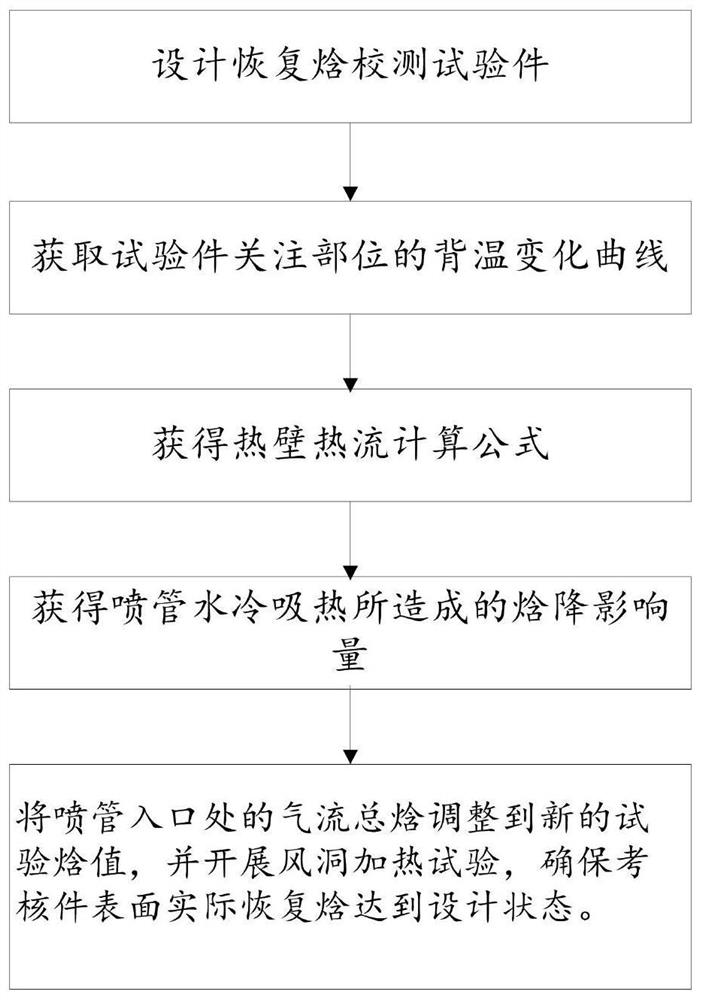

Method used

Image

Examples

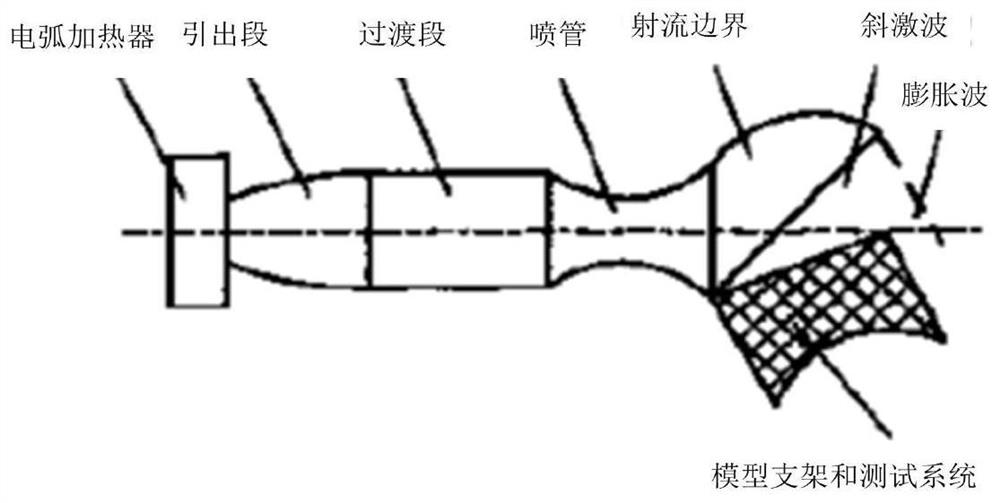

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

[0030] According to one aspect of the present invention, a recovery enthalpy calibration test piece is invented, which consists of three layers, the upper layer and the lower layer are high temperature resistant materials, the middle layer is heat insulation material, and the selection principle of the upper and lower layer materials of the recovery enthalpy calibration test piece In order to: there will be no ejection gas boundary layer phenomenon caused by gas overflow on the surface, the thermophysical parameters of the material and the surface emissivity are clear, the temperature of high temperature resistance is higher than the temperature of the initial design test conditions, the length of the recovery enthalpy calibration test piece, The width is equal to the length and width of the actual test piece, and the thickness of the upper layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com