Mechanical continuously variable transmission

A continuously variable transmission, mechanical technology, applied in mechanical equipment, portable lifting devices, components with teeth, etc., can solve problems such as lack of driving pleasure, V-groove and transmission belt slippage, small transmission torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

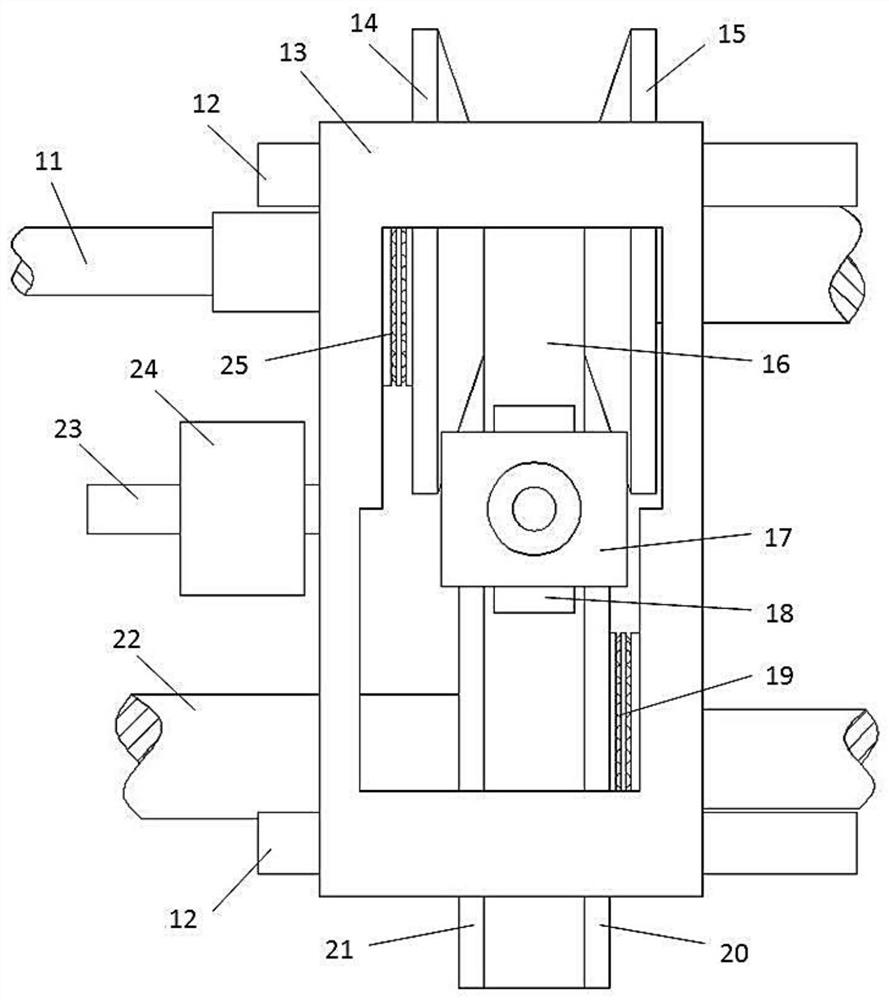

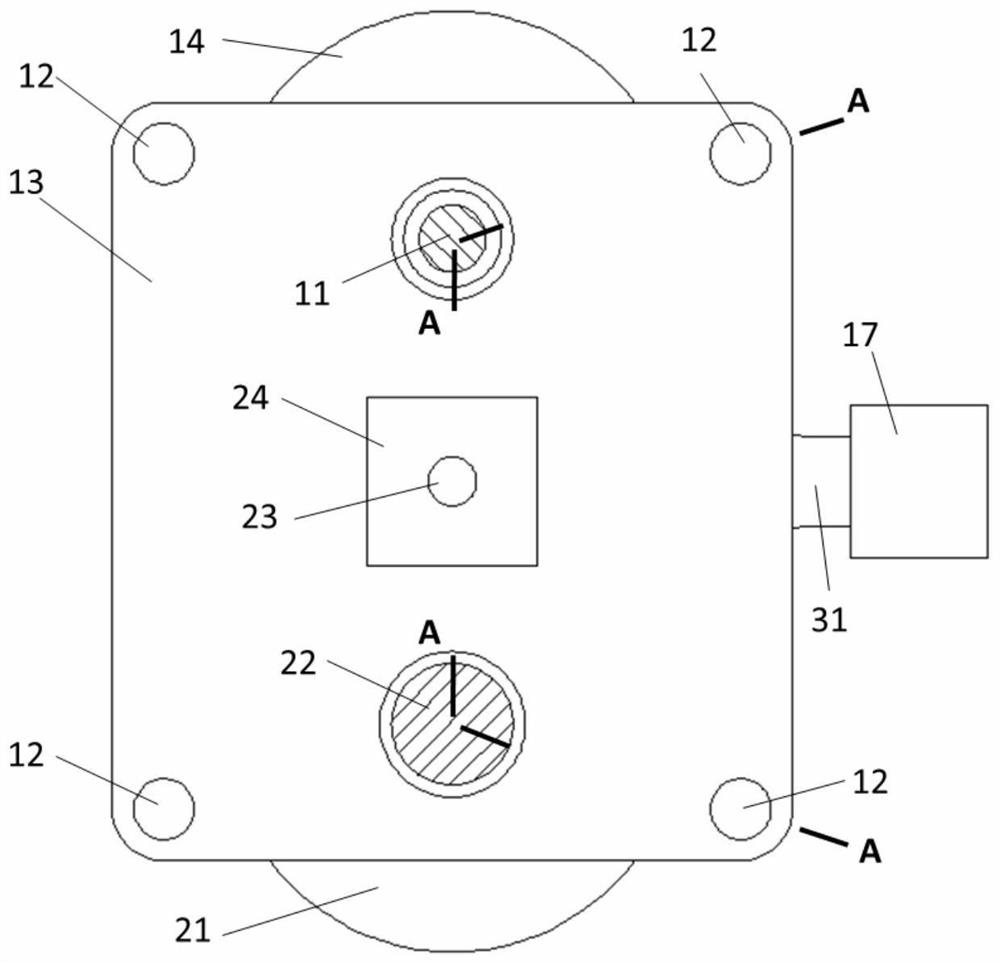

[0019] The present invention uses the tension wheel to provide the pressing force between the V-shaped groove of the continuously variable transmission and the transmission belt, adjusts the tensioning force of the transmission belt through the tension mechanism, and realizes the adjustment of the pressing force between the V-shaped groove and the transmission belt. The axial movement of the cage is controlled by a variable speed control mechanism to realize the change of the transmission ratio of the transmission.

[0020] Below, the technical solution of the present invention will be further described in conjunction with the drawings and specific embodiments of the description:

[0021] The mechanical continuously variable transmission consists of an input shaft 11, a guide rod 12, a cage 13, a driving disc 14, a driving fixed disc 15, a driven disc 20, a driven fixed disc 21, a transmission belt 16, a tensioning mechanism 17, a tensioning Wheel 18, variable speed control me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com