Supporting building with tension and compression reversing characteristic and assembling method thereof

A technology for reversing characteristics and buildings, applied in the direction of building construction, protected buildings/shelters, buildings, etc., which can solve problems that have not yet been researched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

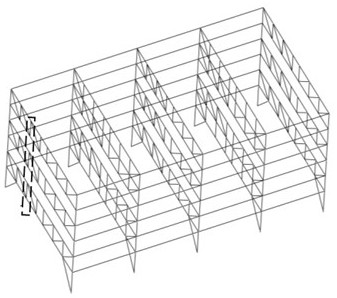

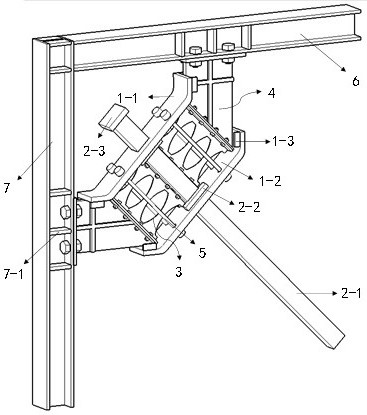

[0043] In one aspect, the present invention provides a supporting structure with tension-compression characteristics, such as Figure 1 to Figure 11 As shown, it includes upper end plate 1-1, lower end plate 1-2, support rod 2, damper 3, wall plate 4, SMA element 5, steel beam 6 and steel column 7, wherein:

[0044] The two ends of the upper end plate 1-1 and the lower end plate 1-2 are respectively bent 45° so that the ends are parallel to the steel beam 6 and the steel column 7, and four rectangular plates 1-3 are welded at the ends to form a limit device. The upper end plate 1-1 A support rod rectangular hole 1-4 and four SMA component circular holes 1-5 are respectively set on the lower end plate 1-2;

[0045] The support rod 2 is made up of a steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com