High-fertilizer-efficiency organic fertilizer and preparation method and application thereof

An organic fertilizer and fertilizer efficiency technology, applied in the field of high fertilizer efficiency organic fertilizer and its preparation, can solve the problems of unbalanced nutrient distribution, low nutrient content, and inability to meet the growth needs of fruit trees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

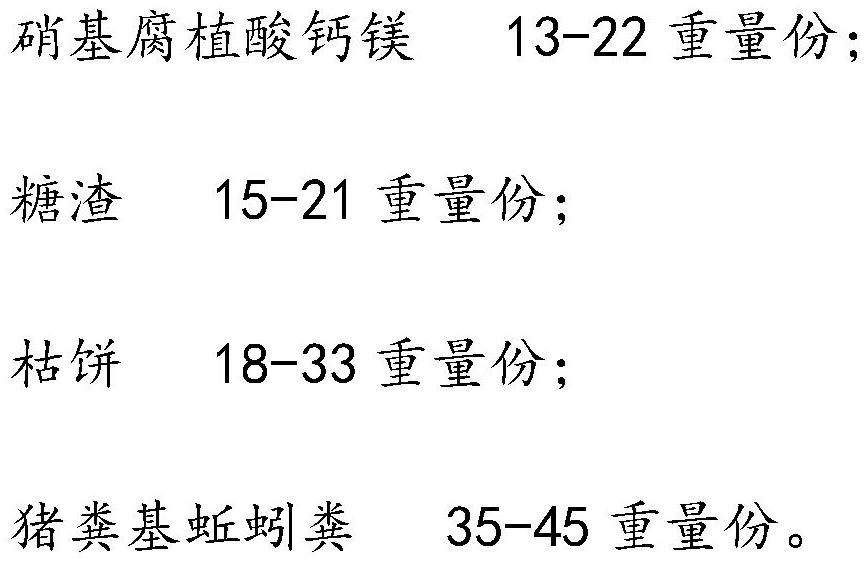

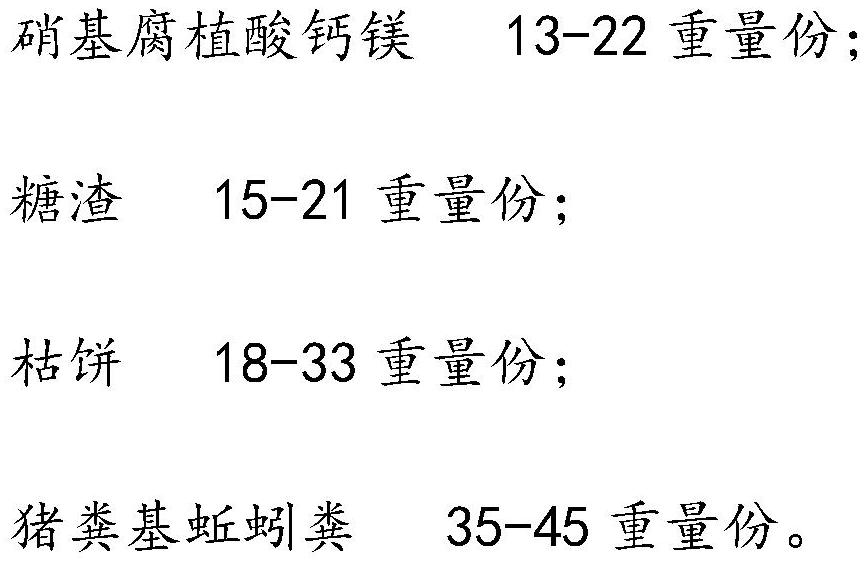

Method used

Image

Examples

preparation example Construction

[0037] (1) Preparation of nitro humic acid crude material: first make concentrated nitric acid into 25%-30% nitric acid solution, then add weathered coal (humic acid content 40%-50% according to the mass ratio of coal acid ratio 0.5-0.8) ), after stirring for 30-40min, obtain the nitrohumic acid crude material;

[0038] (2) Preparation of nitrohumic acid calcium magnesium: 100 parts (dry basis) of the nitrohumic acid crude material prepared above and 50 parts (dry basis) of calcined dolomite crushed to 60 meshes, while adding the former The water with a total weight of 70%-80% is uniformly stirred by a mixer and then reacted at 90° C. for 4 hours to obtain calcium magnesium nitrohumate after aging.

[0039] The sugar residue is the waste residue produced after starch saccharification in the production process of monosodium glutamate; the dry cake is rapeseed cake or peanut cake, which is cake-shaped residue after oil extraction from rapeseed or peanut seeds; the pig manure bas...

Embodiment 1-5

[0057] Embodiment 1-5 relates to a kind of high fertilizer efficiency organic fertilizer, and its preparation method is as follows:

[0058] The calcium magnesium nitrohumate, sugar residue, dry cake and pig manure-based vermicompost are fully mixed in proportion to obtain a mixed material system. Grinding the mixed material system to obtain a mixed material system with a particle size of 0.25 mm, then adding binder and water to the mixed material system, mixing to make a honeycomb coal shape with a circular cross section, and then heating at 50°C Dried, that is.

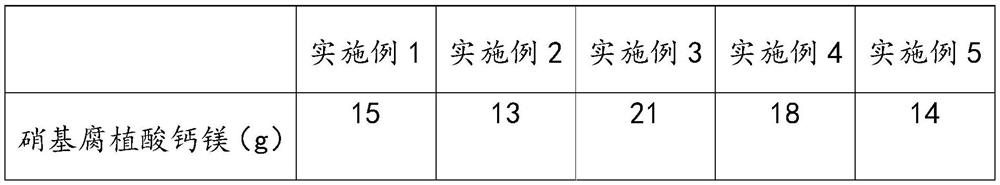

[0059] Among them, the addition amount of calcium magnesium nitrohumate, sugar slag, dry cake, pig manure-based vermicompost and binder are shown in Table 1;

[0060] Table 1. The concrete formula of embodiment 1-5

[0061]

[0062]

[0063] Table 2. The organic fertilizer cross-sectional diameter, height, through hole diameter and number of embodiment 1-5

[0064]

Embodiment 6

[0066] The only difference between this embodiment and Example 3 is that, in this embodiment, the organic fertilizer is prepared according to the following steps:

[0067] Fully mix calcium magnesium nitrohumate, sugar residue, dry cake, pig manure-based vermicompost and binder in proportion to obtain a mixed material system, crush and grind the mixed material system to obtain a mixed material with a particle size of 0.25mm system, and then dried at 50°C to obtain powdered organic fertilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com