A concrete waste recycling system

A concrete waste and waste technology, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problem of restricting the promotion and popularization of concrete waste recycling and reuse, low impermeability of new concrete, and the use of To solve problems such as limited fields, achieve the effect of promoting popularization of use, reducing transportation burden, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

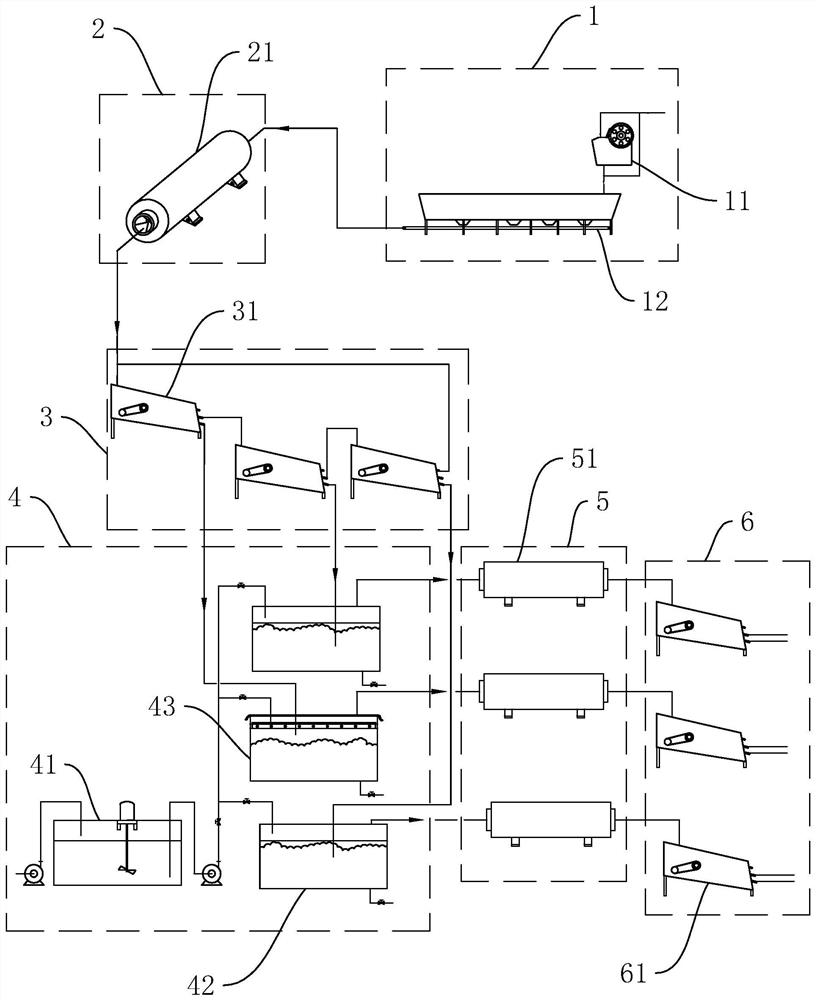

[0068] as attached figure 1 As shown, a concrete waste recycling system includes the following units arranged in order of flow: waste crushing unit 1, drying unit 2, first sorting unit 3, sealing unit 4, drying unit 5 and second Sorting unit 6.

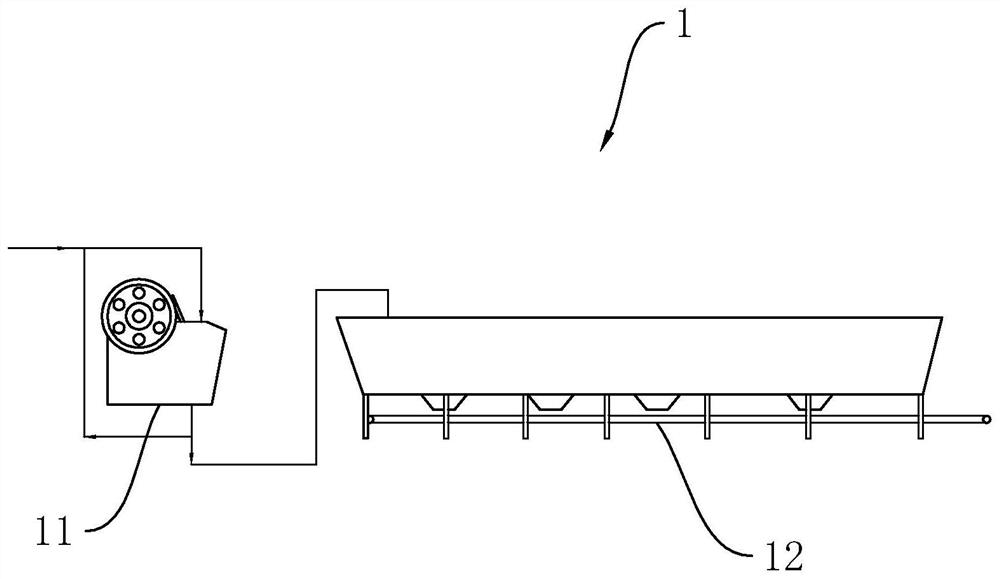

[0069] as attached figure 2 As shown, in the waste crushing unit 1, the concrete waste is crushed to a particle size of less than 10 cm to obtain waste aggregates. The crushing in the waste crushing unit 1 can be determined according to the actual situation. For example, if the site condition of the recycling system is a construction site or a commercial concrete station, the amount of concrete waste, etc., it can be crushed manually using tools such as jacks and electric hammers, or There are mechanical equipment such as concrete crusher 11 (also known as jaw crusher) for crushing. In this embodiment, the present invention is described systematically, and concrete crusher 11 is used as an example.

[0070] The waste aggregates cr...

Embodiment 2

[0096] as attached Figure 8 As shown, a concrete waste recycling system is based on the first embodiment, the difference is that it also includes a residual alkali removal unit 7, and the process of the residual alkali removal unit 7 is located between the waste crushing unit 1 and the drying unit 2 During this period, the residual alkali unit 7 is used as the next process unit of the waste crushing unit 1, and the residual alkali unit 7 is used as the previous process unit of the drying unit 2.

[0097] as attached Figure 9 As shown, the residual alkali removal unit 7 includes a soaking tank 71 and a water supply pump 72 . The immersion pool 71 includes a third pool body 711. The immersion pool 71 is also connected with a sewage pipe 712 at the bottom of the third pool body 711. The sewage pipe 712 is also provided with a controllable sewage valve outside the third pool body 711. 7121. The water supply pump 72 is controllable to open and close, and its water inlet is com...

Embodiment 3

[0103] as attached Figure 10 As shown, a concrete waste recycling system is based on the second embodiment, the difference is that it also includes an aging unit 8 . The process of the aging unit 8 is located between the sealing unit 4 and the drying unit 5 , the aging unit 8 is the next process unit of the sealing unit 4 , and the aging unit 8 is the previous process unit of the drying unit 5 .

[0104] as attached Figure 11 As shown, the aging unit 8 includes an aging room 81, which can be a stacking area, a pool body or a warehouse, and the pool body is selected here. The number of aging chambers 81 is determined according to the actual situation, and the number of aging chambers 81 is at least the number of intervals of particle diameters sorted by the first sorting unit 3, where the number of aging chambers 81 is three.

[0105] as attached Figure 10 As shown, the plugged aggregates are picked up and stacked in the aging chamber 81 after being soaked or soaked in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com