Tobacco factory sheet wastewater treatment process

A waste water treatment, waste water technology, applied in the direction of water/sewage treatment, natural water treatment, special compound water treatment, etc., can solve the problems of backward technology, low treatment efficiency, easy to exceed the standard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

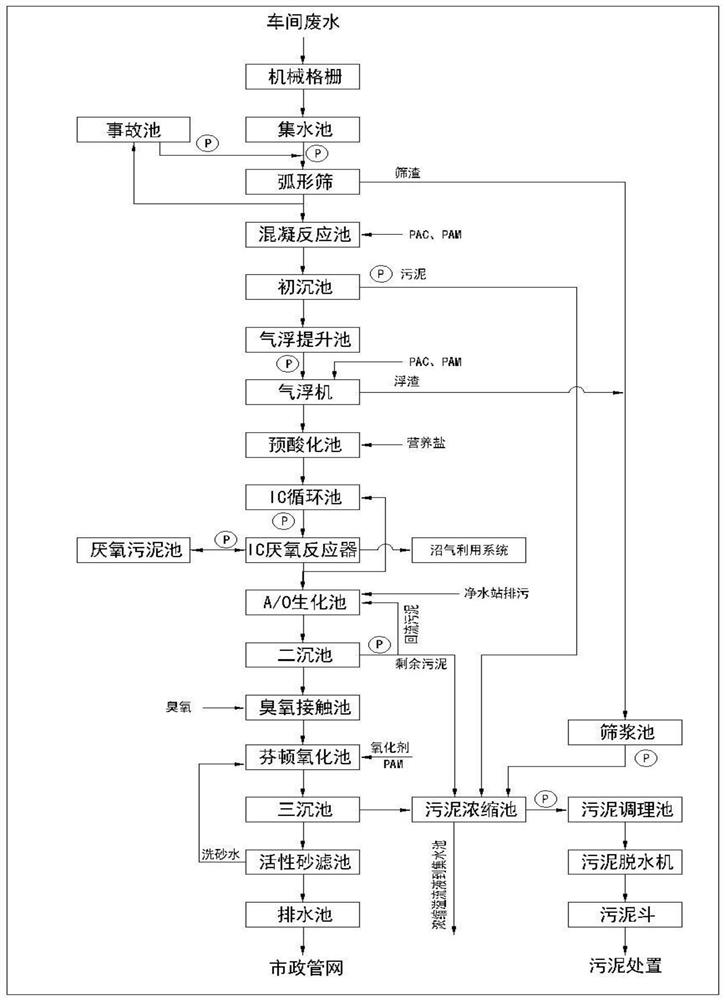

[0026] like figure 1 As shown, the present embodiment provides a process for the treatment of waste water from cigarette factories, which is characterized in that it includes the following steps:

[0027] Step 1. The workshop wastewater first passes through the mechanical grille to remove the coarse floating objects, and then flows into the sump by itself;

[0028] Step 2. The waste water in the sump is pumped by the lifting pump to the curved sieve for filtration, and the fine debris and other suspended matter in the waste water are removed. When the waste water in the workshop is normal, go directly to step 4. When the waste water in the workshop is abnormal, go to step 3;

[0029] Step 3. After the wastewater is filtered by the curved screen, it is switched to the accident pool for storage (if the water collection lift pump fails, the workshop wastewater is directly switched to the accident pool for storage). After the system is stable, the small flow of the accident wastew...

Embodiment 2

[0033] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0034] In step 5, the advanced treatment system consists of an ozone contact tank, a Fenton oxidation tank, a three-settling tank, and an active sand filter. The use of the advanced treatment system is as follows:

[0035] a. When the wastewater treated by the secondary sedimentation tank does not need Fenton oxidation treatment, it will reach the standard of acceptance after being decolorized by the ozone in the ozone contact tank, and then enter the municipal sewage treatment plant for further treatment.

[0036] b. If it is necessary to meet the first-class A standard in the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002), the wastewater treated in step a needs to be treated with Fenton oxidation. At this time, the effluent from the ozone contact pool enters After the Fenton oxidation tank, the refractory organic matter in the wastewater is oxidatively ...

Embodiment 3

[0038] This embodiment is further optimized on the basis of embodiment 1 or 2, specifically:

[0039] In step 5, the biogas produced by the IC anaerobic reactor is sent to the gas cabinet for storage, and then sent to the power center boiler for combustion and utilization after dehydration and desulfurization (when not in use, it is burned by a torch); the anaerobic sludge of the IC anaerobic reactor It enters the anaerobic sludge tank for storage (it can be sold outside or supplemented when it is abnormal).

[0040]The residue from the curved screen and the scum from the air flotation machine enter the sieving tank, and then pumped to the sludge thickening tank; the sludge from the primary settling tank, the remaining sludge from the secondary settling tank, and the sludge from the tertiary settling tank are pumped to the sludge thickening tank , concentrated and then pumped to the sludge conditioning tank; the conditioned sludge is pumped to the sludge dehydrator for treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com