Material conveying machine for food processing

A food processing and conveyor technology, applied in the field of conveyors, can solve problems such as difficulty in ensuring food integrity and food damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

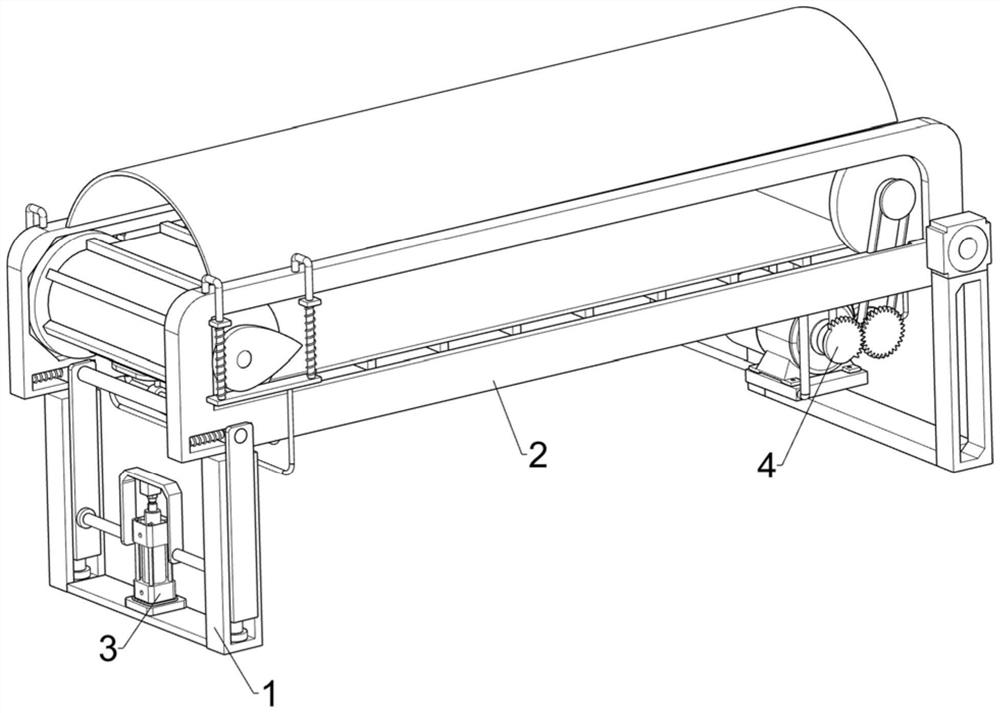

[0021] A conveyor for food processing, such as Figure 1-3 As shown, it includes a base 1, a frame 2, a lifting mechanism 3 and a conveying mechanism 4, the base 1 is placed on the left and right sides, the right base 1 and the frame 2 are connected in a rotating manner, and the left base 1 and the frame 2 is provided with lifting mechanism 3, and frame 2 is provided with conveying mechanism 4.

[0022] When using this device for food delivery, the lifting mechanism 3 will first be controlled to start working. The lifting mechanism 3 can adjust the height on the left side of the frame 2. When the left side of the frame 2 reaches the required height, the lifting mechanism 3 can be controlled to stop. Work, then control the delivery mechanism 4 to start working, the delivery mechanism 4 can transport the food on the right side to the left side of the frame 2, after all the food delivery is completed, control the delivery mechanism 4 to stop working.

[0023] Lifting mechanism 3...

Embodiment 2

[0028] On the basis of Example 1, such as Figure 4 Shown, also include cam 5, the 3rd fixed frame 6, telescopic rod 7, the second spring 8, touch plate 9, the 3rd connecting frame 10, crank 11, the 4th fixed frame 12, guide sleeve 13 and hair brush 14. The drive shaft on the left side of the conveyor belt 48 is provided with cams 5 on the front and rear sides, the left side of the frame 2 is provided with a third fixed frame 6, and the left and right sides of the third fixed frame 6 are provided with telescopic rods. 7. A touch plate 9 is provided between the bottom of the telescopic rod 7, and the touch plate 9 cooperates with the cam 5. A second spring 8 is provided between the touch plate 9 and the left and right sides of the third fixed frame 6, and the front and rear sides A third connection frame 10 is connected between the lower right side of the touch plate 9, and the middle part of the third connection frame 10 is rotatably provided with a crank 11. The crank 11 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com