Low-voltage switch drawer cable clamp spring replacement device and method

A low-voltage switch and circlip technology, which is applied in the field of low-voltage switch drawer cable circlip replacement devices, can solve the problems of inability to guarantee the clamping force of a primary circuit connector, failure to meet inspection standards, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment and accompanying drawing, the present invention is further described:

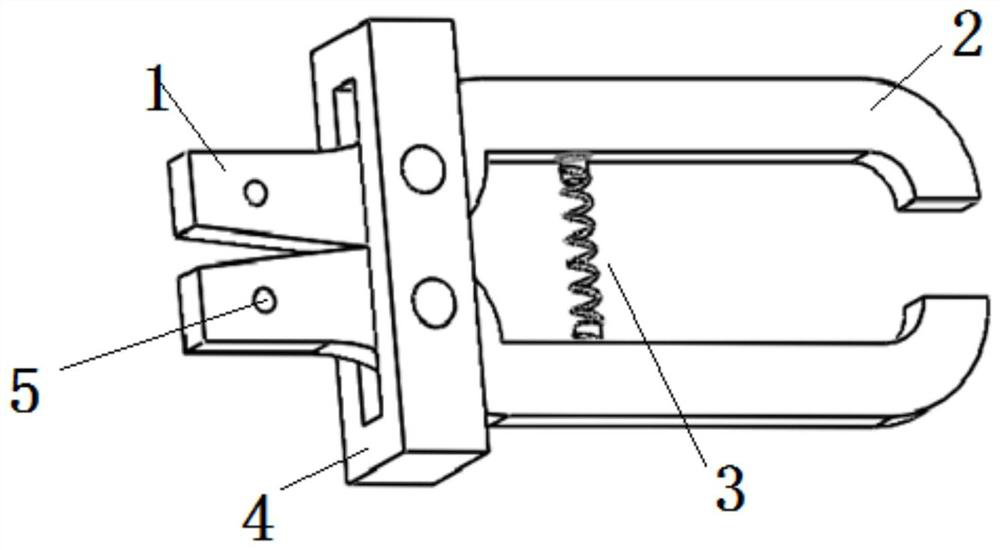

[0027] Such as figure 1 As shown, the present invention provides a low-voltage switch drawer cable clamp replacement device, which includes a clamp body 1, a handle 2, a spring 3, a handle support block 4 and a cylindrical protrusion 5.

[0028] The two caliper bodies 1 are fixedly connected with the two handles 2 respectively through the handle support block 4 and the pin, and the spring 3 is fixedly connected in the middle of the two handles 2 with the pin, so that the circlip replacement device is assembled into a whole.

[0029] The clamp body 1 is made of stainless steel.

[0030] A cylindrical protrusion 5 is provided on the surface of the pliers body 1, and the cylindrical protrusion 5 is firmly connected with the circlip, so that the circlip can be quickly removed and reinstalled.

[0031] The tail of the pliers body 1 is circular.

[0032] Spring 3 pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com