Circular saw blade bracket and clamping device

A circular saw blade and bracket technology, which is used in the tool manufacturing of sawing machine devices, tool dressing of sawing machine devices, metal sawing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

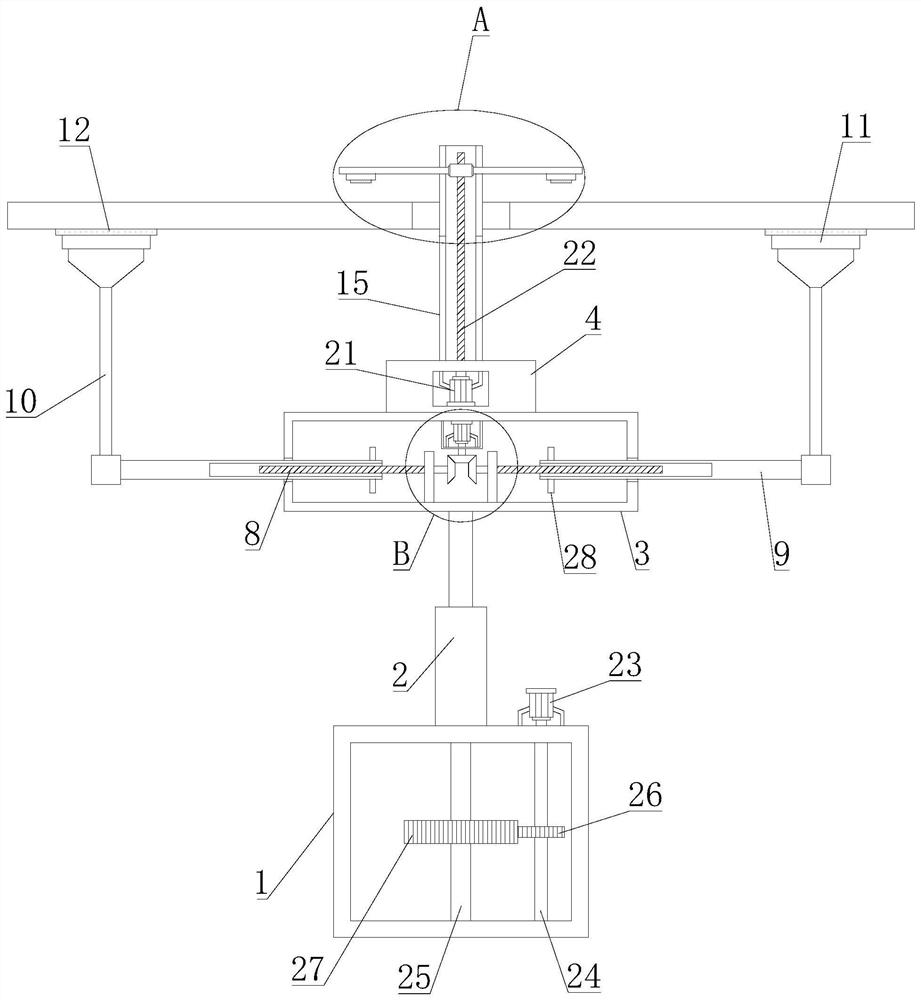

[0035] This embodiment provides a circular saw blade bracket, such as figure 1 As shown, it includes an axial support mechanism and a radial support mechanism. The radial support mechanism is used to apply pressure to one side of the circular saw blade, and the axial support mechanism is used to apply pressure to the other side of the circular saw blade; the axial support The mechanism cooperates with the radial support mechanism to realize the pressing and fixing of the circular saw blade.

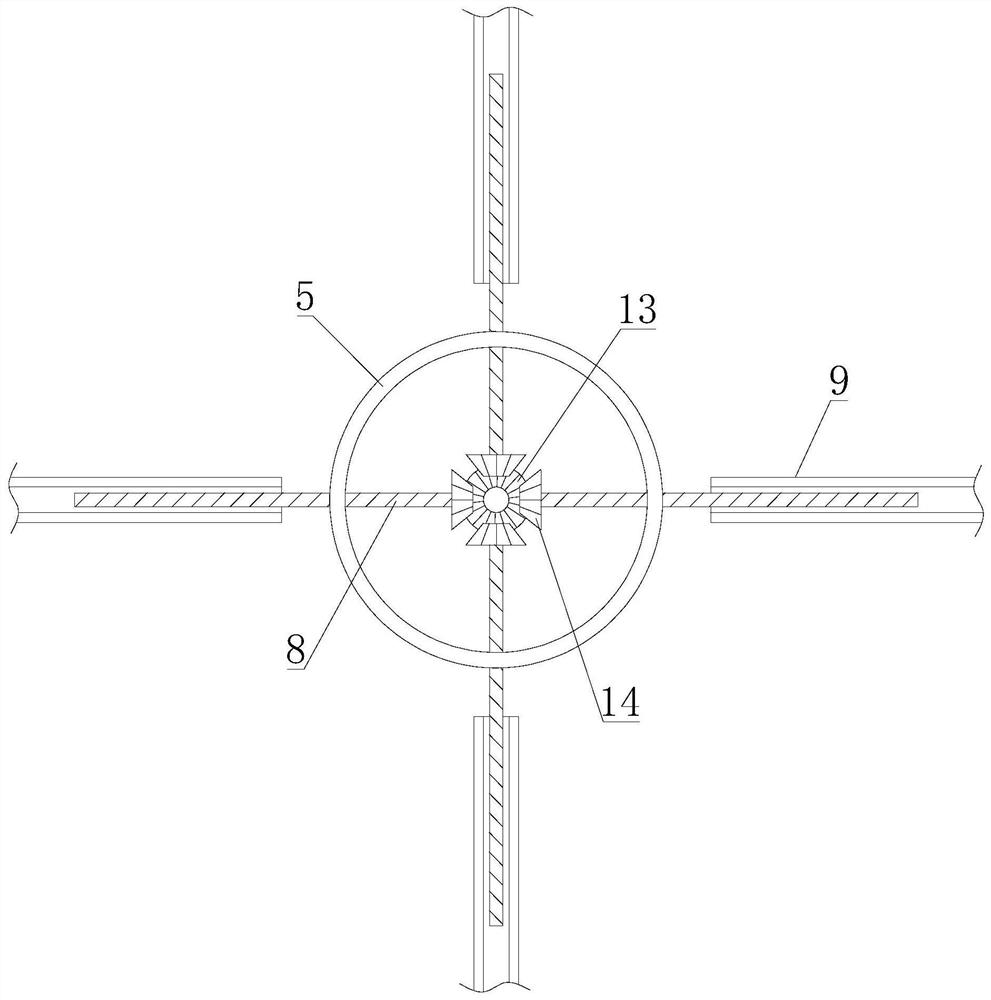

[0036] The radial support mechanism includes a driving mechanism, a guiding mechanism, and a supporting mechanism. The driving mechanism is connected to a plurality of guiding mechanisms, and each guiding mechanism is connected to a supporting mechanism. In this example, if image 3 As shown, there are four guide mechanisms arranged evenly.

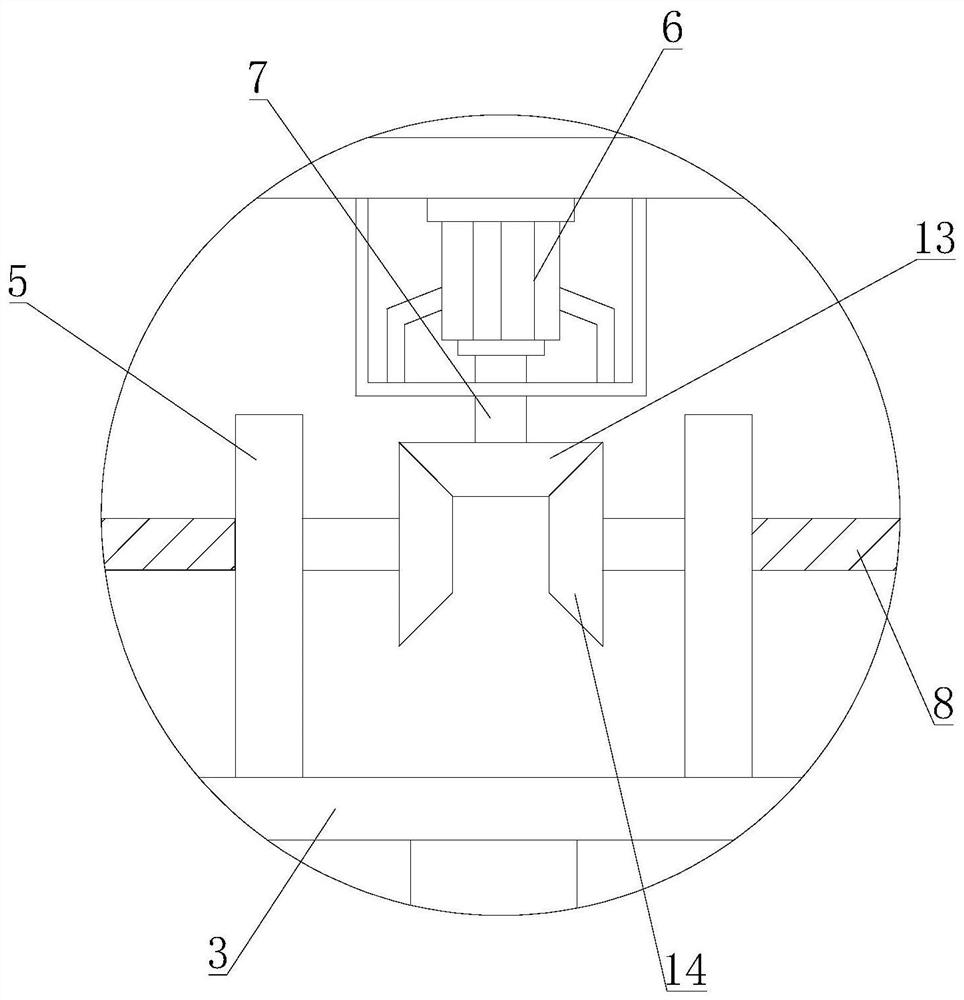

[0037] Further, such as figure 2 As shown, the drive mechanism includes a first motor 6 and a bevel gear set, and the first motor 6 is connected...

Embodiment 2

[0053] This embodiment provides a circular saw blade clamping device, such as figure 1 As shown, it includes a driving device and the bracket described in Embodiment 1, and the driving device is fixedly connected with the bracket.

[0054] Specifically, the driving device includes a third motor 23, a gear transmission mechanism, a second support member 2, and a fixed base 1. The third motor 23 is connected to one end of the second support member 2 through a gear transmission mechanism, and the second support member 2 The other end is fixedly connected to the side of the connection box 3 (the side opposite to the connection base 4). The second supporting member 2 may be a telescopic rod.

[0055] The gear transmission mechanism is installed inside the fixed base 1 , and the third motor 23 is installed outside the fixed base 1 . Further, the gear transmission mechanism includes a second transmission shaft 24, a third transmission shaft 25, a first gear 26, and a second gear 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com