Isostatic pressing soft die sleeve weight-limiting isovolumetric powder filling process and device

A technology of isostatic pressing and soft moulding, applied in the field of static pressing, can solve the problems of insufficient roundness, cylindricity, and inability to control the size and control of the green compact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

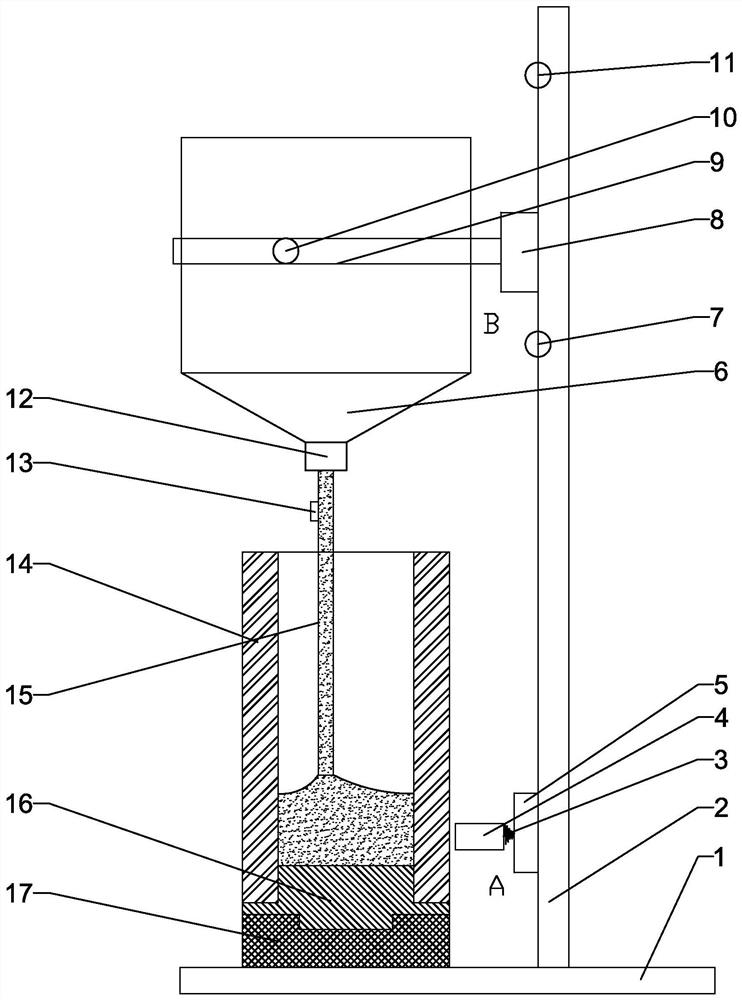

[0033] A kind of isostatic pressing soft mold sleeve weight-limiting equal-capacity powder filling process of the present invention comprises the following steps:

[0034] A. Use a weighing device to fill a certain weight of powder into the mold sleeve. The certain weight refers to weighing the total weight of the powder according to the preset multi-stage feeding mode to weigh the weight corresponding to one of the required powders, and each time The weight of the powder required for each segment is the same;

[0035] B. The powder of a certain weight is gradually filled into the mold sleeve in a spiral manner, so that the powder in the mold sleeve gradually increases from bottom to top; in the process of increasing the powder material, a vibrating device is used to shake the powder in the mold sleeve. The material is vibrated synchronously; until a certain weight of powder is filled;

[0036] C. Use a distance measuring device to measure the powder filling height of the cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com