Electromagnetically driven liquid atomizing device

An electromagnetic drive, liquid atomization technology, applied in the direction of tobacco, etc., can solve the problems of uneven heating of smoke liquid, liquid leakage of atomizer, and reducing the probability of liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below through the examples and accompanying drawings, the purpose is only to better understand the content of the present invention, but not to limit the present invention.

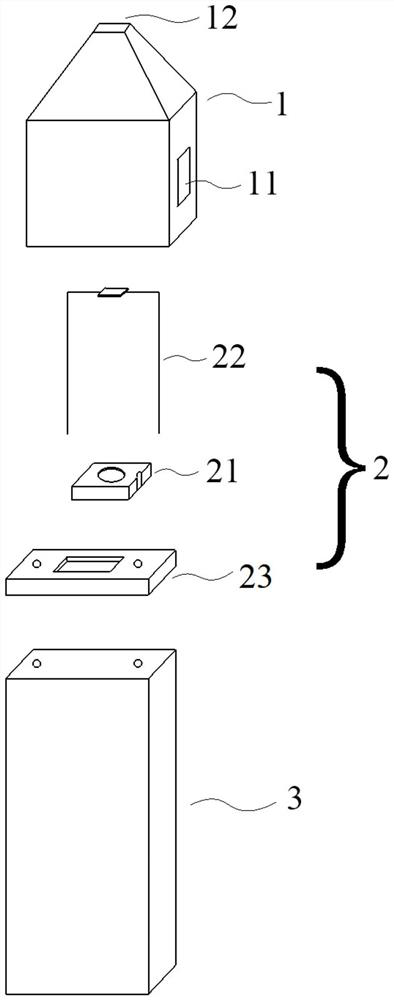

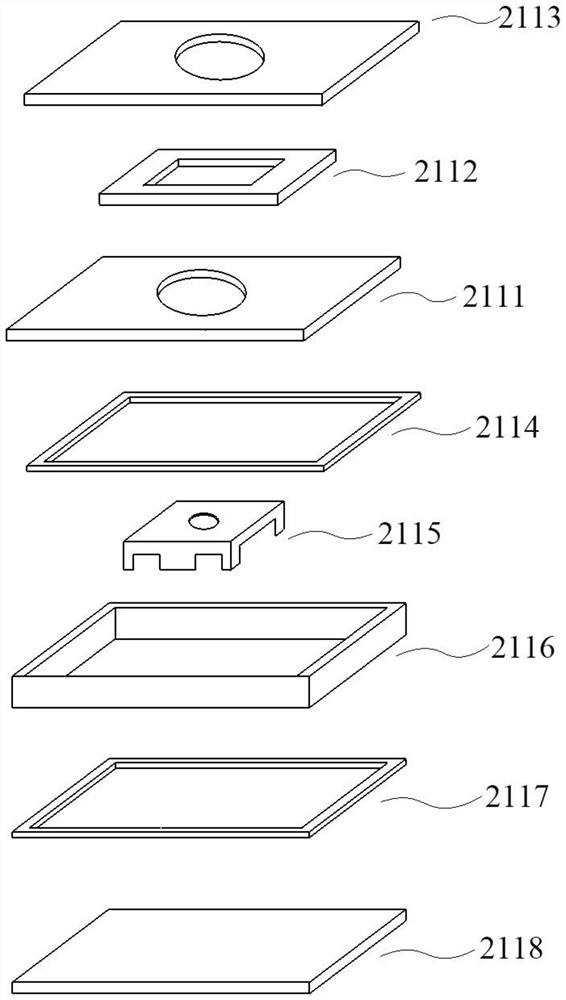

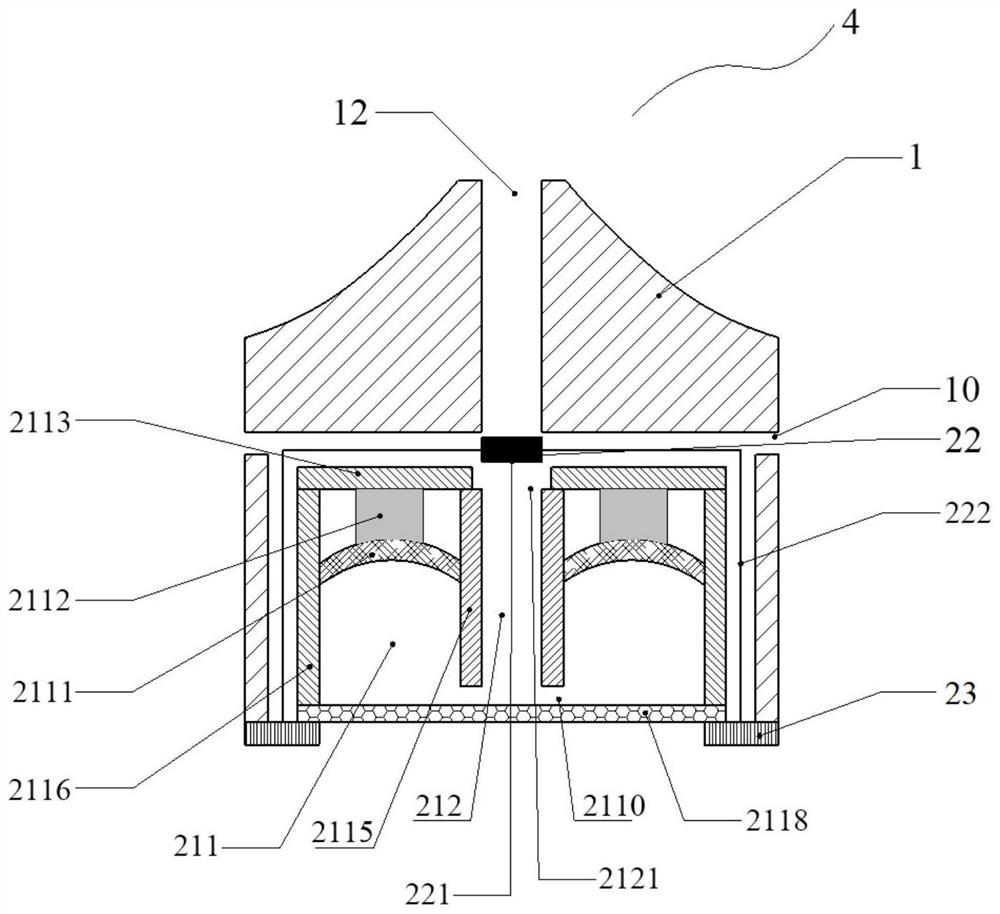

[0036] Such as figure 1 As shown, the electromagnetically driven single-drop atomization device of the present invention includes a suction nozzle end cover 1, an atomizing core 2 and an electromagnetic driving rod 3 connected in sequence; the atomizing core 2 includes a liquid storage chamber 21, an electric heating element 22 and a base Seat 23. Such as figure 2 As shown, the liquid storage bin 21 is composed of a pressing sheet 2113, a permanent magnet sheet 2112, an elastic diaphragm 2111, an upper sealing gasket 2114, an extrusion cavity frame 2115, a driving cavity 2116, a lower sealing gasket 2117 and a liner from top to bottom. The bottom 2118 is assembled, and the inner volume of the liquid storage bin of the present invention is 1-2mL. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com