Fragrance slow-release material, heating rod, cigarette holder rod, preparation method thereof and application thereof in heat-not-burn tobacco products

A heat-not-burn, slow-release material technology, applied in the fields of tobacco, applications, smokers’ products, etc., can solve the problem of flavor slow-release technology with limited technical means, lack of production and application value, failure to reach the cracking temperature of microcapsule wall materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Flavor A is a commonly used tobacco flavor, which contains some common volatile and semi-volatile flavor components, mainly including: water, ethyl butyrate, ethyl 2-methyl butyrate, ethyl isovalerate, furfural , Hexyl caproate, 3-methyl-pyrazine, 2-ethyl-3-methylpyrazine, benzaldehyde, acetophenone, macrostigmatrienone, geranyl acetone, β-damascenone, Damascone, menthol, methyl phenylacetate, tobacco extract, fig extract, apple extract, jujube tincture, vanilla bean tincture, benzoin balm, licorice liquid extract, etc.

[0072] In order to promote the slow and uniform release of essence A during the heating stage, the weight of this scheme is 17g / m 2 Highly absorbent hemp pulp paper (using Manila hemp pulp, water absorption ≈5g / m 2 ) is the support material to adsorb and fix the essence A. The specific implementation method is as follows: Weigh 360g of essence A, 90g of hydroxypropyl methylcellulose, and 3kg of 85% ethanol solution and mix them together. After the ma...

Embodiment 2

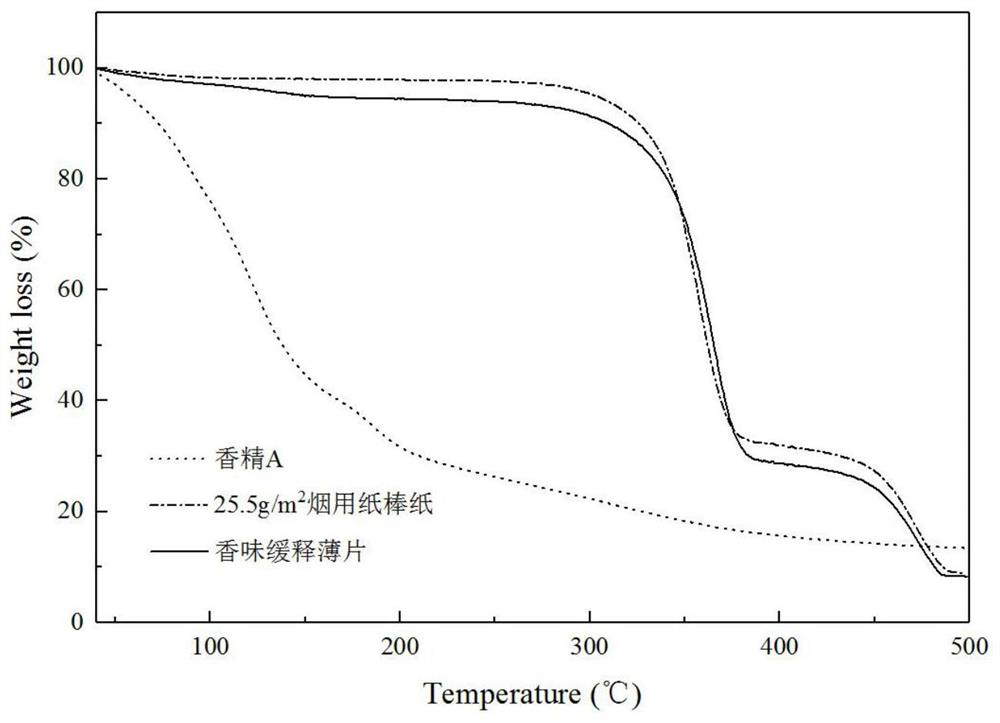

[0076] Another kind of optimized embodiment adopts the highly absorbent cigarette paper stick paper (adopting Canadian northern wood wood pulp, water absorption ≈7.5g / m2) with a grammage of 25.5g / m2 2 ). The specific steps are as follows: first coat the essence A on the paper, remove the solvent, and then coat a layer of film material on the surface.

[0077] The specific steps of this scheme are as follows: Weigh 360g of essence A, dilute to 3kg with 85% ethanol solution and stir evenly. The fragrance solution was coated on the paper material, and the coated paper material was transported to the drying box along with the conveyor belt, and dried at a low temperature of 50° C. to remove moisture, and the fragrance slow-release material A was obtained. Then prepare 3kg of 3% hydroxypropyl methylcellulose solution and apply it on the material A to obtain the final fragrance sustained-release material. By comparing the weight of the paper before and after coating, it can be see...

Embodiment 3

[0080] In another optimized embodiment, the essence A and the film material are mixed and coated on the paper, and after the solvent is removed, a layer of film material is coated on the surface. This program uses highly absorbent cigarette stick paper with a grammage of 25.5g / m2 (Canadian northern wood pulp, water absorption ≈7.5g / m2) 2 ).

[0081] The specific steps are as follows: Weigh 500g of essence A, 90g of hydroxypropyl methylcellulose, and 2410g of 85% ethanol solution and mix them together, stir evenly after completely dissolving, and obtain the flavoring coating liquid. The fragranced coating solution is applied to the paper material by scraping, and the coated paper material is transported to the drying box along with the conveyor belt, and after drying at 50°C to remove moisture, the fragrance sustained-release material A is obtained. . It is 3% hydroxypropyl methylcellulose solution that preparation 3kg concentration is again, is coated on the fragrance slow-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com