a cable conveyor

A cable conveyor and motor technology, applied in cable laying equipment, transportation and packaging, transportation of filamentous materials, etc., can solve the problems of reducing cable insulation, leakage risk, loose and deformed insulation layer, etc., and reduce the damage per unit area. The effect of increasing the contact area, preventing the risk of leakage, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

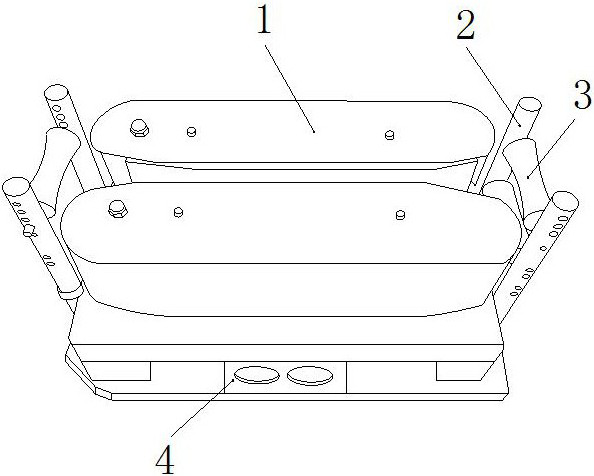

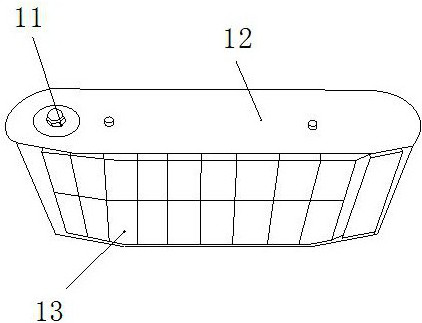

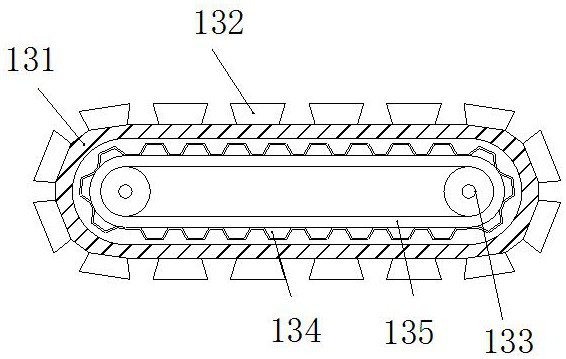

[0024] as attached figure 1 to attach Figure 4 Shown:

[0025] The present invention provides a cable conveyor, the structure of which includes a conveyor 1, a clamping column 2, a roller 3, and a motor 4. The outer side is welded and connected, and the roller 3 is connected to the inner shaft of the clamping column 2. The transporter 1 includes a rotating shaft 11, a side plate 12, and a clamping belt 13. The rotating shaft 11 is connected to the left end of the side plate 12 by bolts. The side plate 12 is in clearance fit with the outside of the clamping belt 13, and the clamping belt 13 is meshed and connected with the outside of the rotating shaft 11. The shape of the roller 3 is a cylindrical shape that gradually shrinks from the outside to the inside, and the number is two. 1 is distributed symmetrically around the center, supporting the entry and exit and output of the cable to prevent the cable's own weight from pulling the insulation layer.

[0026] Wherein, the c...

Embodiment 2

[0031] as attached Figure 5 to attach Figure 7 Shown:

[0032] Wherein, the touch plate 32d includes a support block d1, a backing plate d2, a connecting shaft d3, and a connecting shaft d4. Side welding connection, the connecting shaft d3 is connected to the left axis of the middle part of the backing plate d2, and the middle connecting shaft d4 is hingedly connected to the left lower end of the backing plate d2, and the number of the backing plates d2 is two, with the middle connecting shaft d4 The center is distributed symmetrically up and down, and forms an angle with an obtuse angle, and the upper and lower offsetting force is applied to the cable, which is beneficial to increase the stress area of the cable surface and reduce the average stress of the cable. Protect the cable insulation layer from cracking .

[0033] Wherein, the support block d1 includes a support plate r1, a fixed shaft r2, a spring plate r3, and a ball r4, the inner side of the support plate r1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com