Organic light emitting diode device and preparation method thereof, display substrate and display device

A technology of light-emitting diodes and display substrates, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., and can solve problems such as poor mura, smaller color gamut of panels, and reddish white screens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

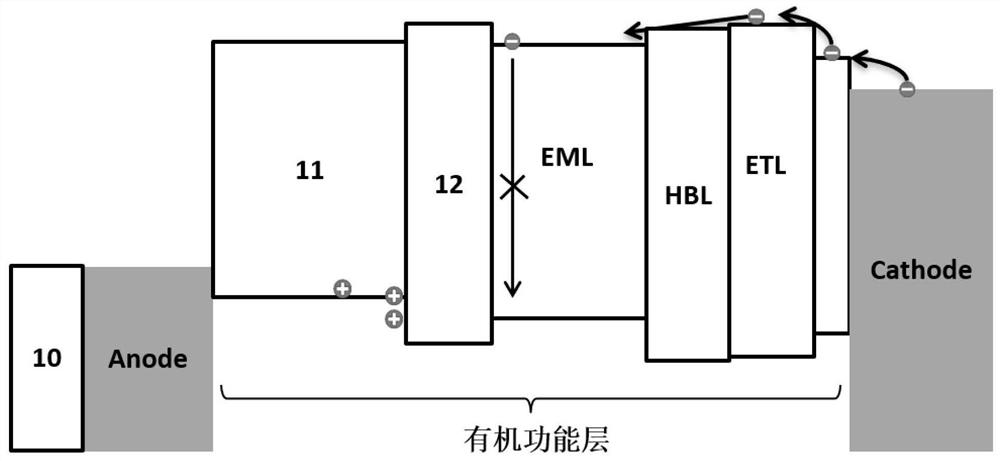

[0045] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

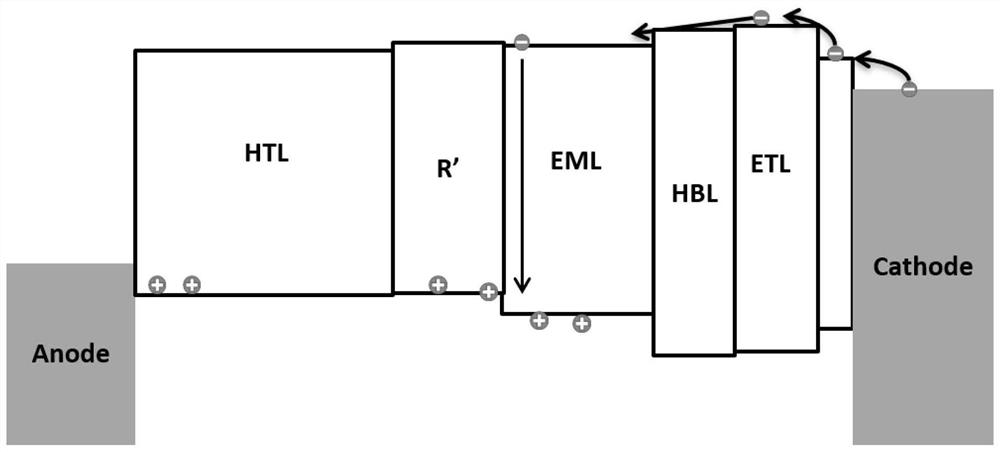

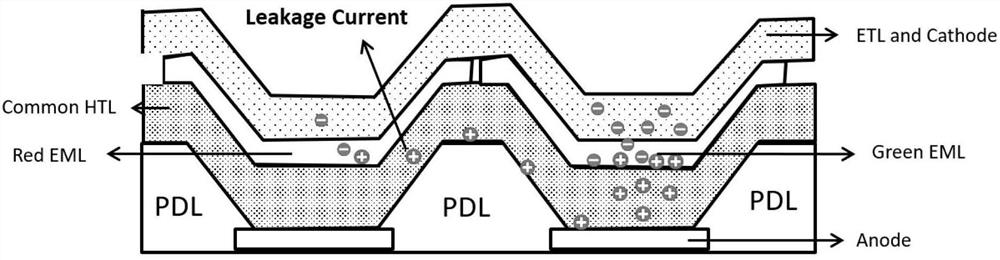

[0046] Since the brightness of the OLED device is determined by the current of the OLED device, the control of the current by the drive transistor DTFT will directly affect the luminous intensity of the OLED screen. As the resolution of OLED screens is getting higher and higher, the pixel light-emitting area is getting smaller and smaller. Under the condition that the brightness of the screen remains unchanged, the current of each pixel will become smaller and smaller, especially in extremely low grayscale. current. The smaller the current, the more difficult it is to precisely control the driving transistor DTFT. Therefore, various mura defects will occur on the OLED screen at low gray levels. In addition, when the screen is in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com