A power turbine inlet guide for a combustion-driven compressor unit

A compressor unit and power turbine technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of poor realizability, long axial dimension, complex structure, etc., to reduce the loss of aerodynamic performance, increase the number, The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

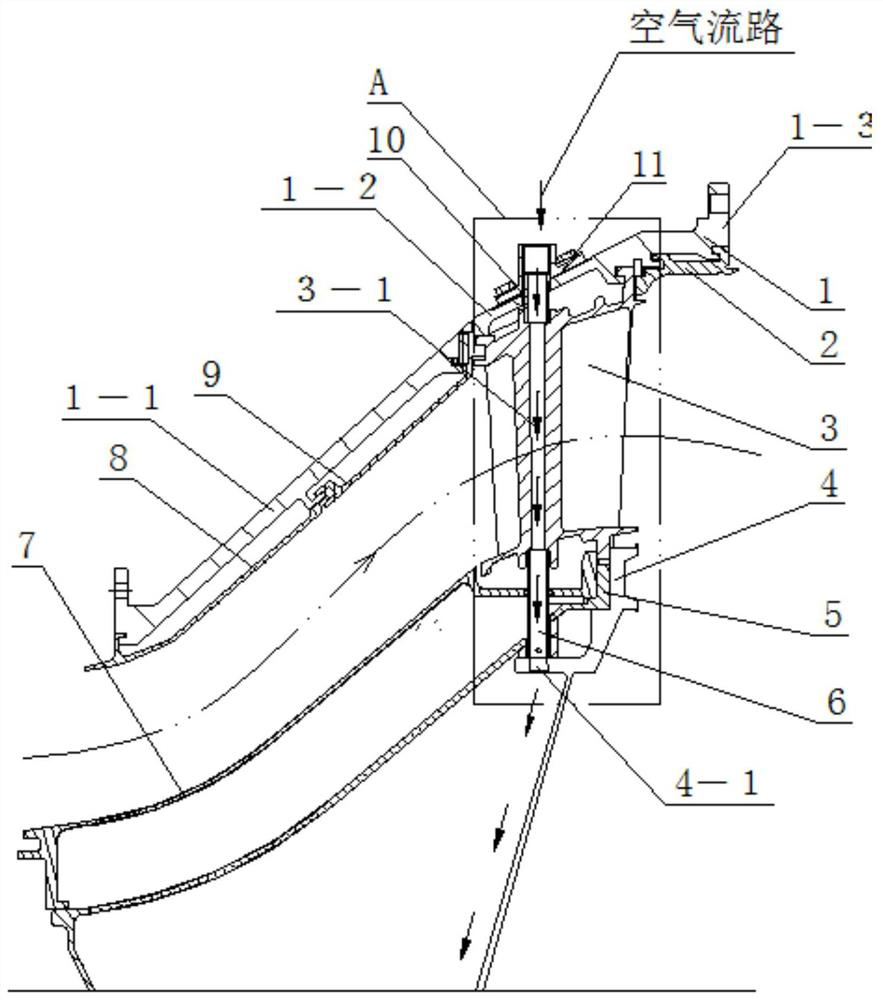

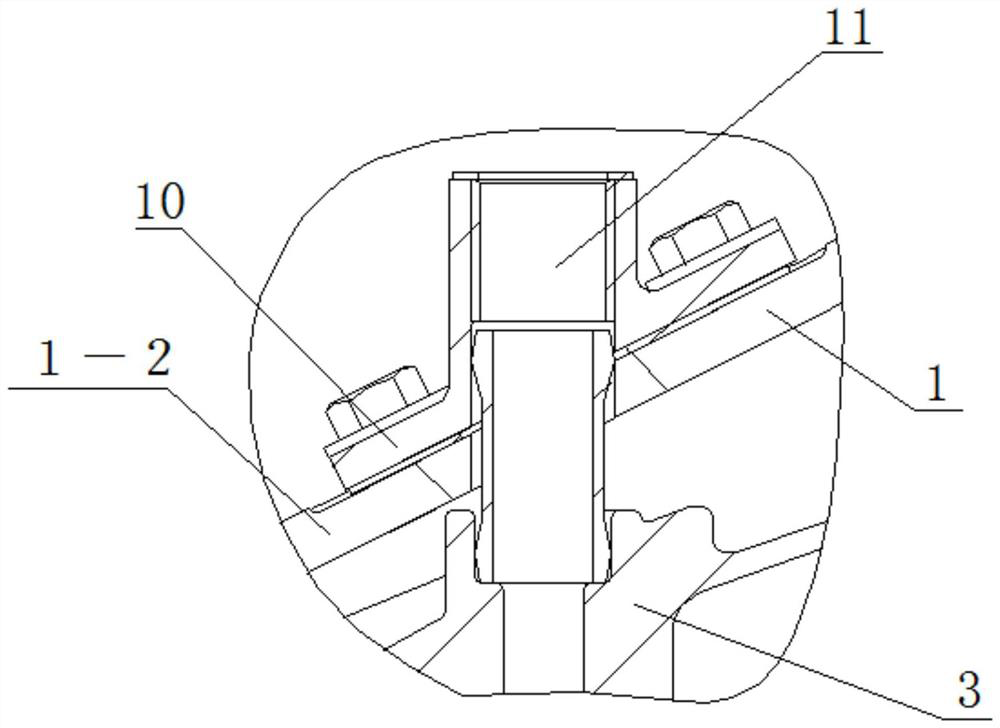

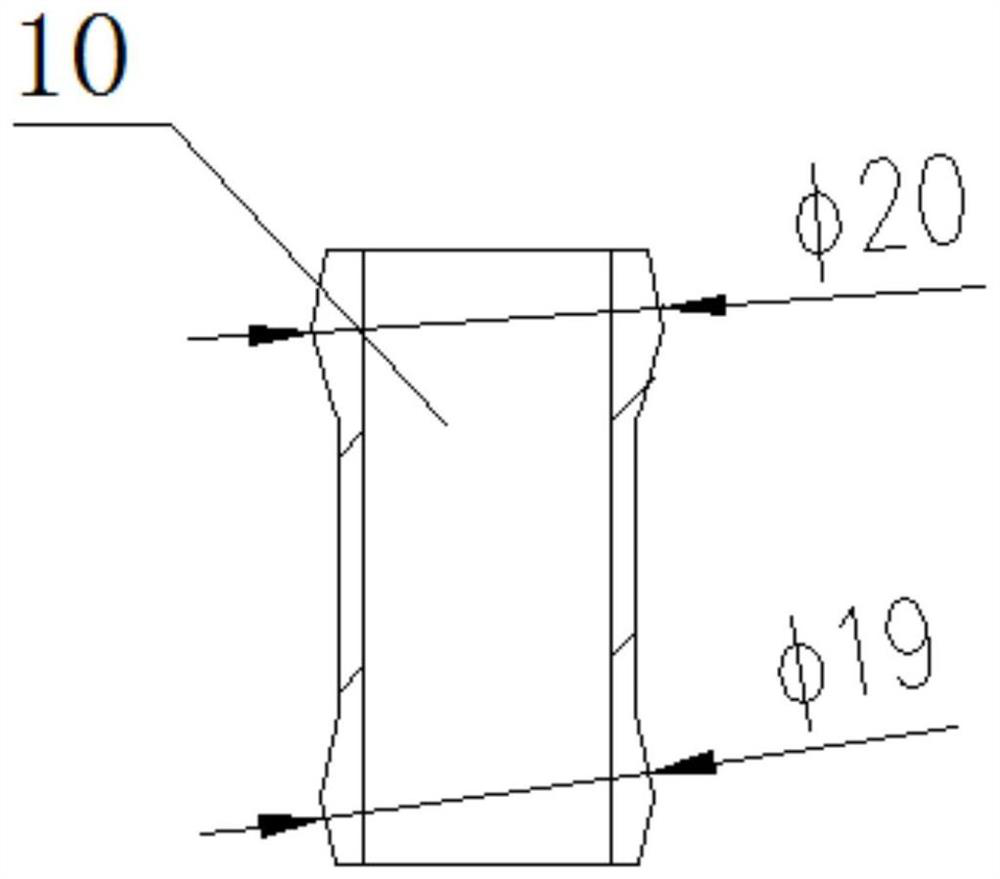

[0026] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a power turbine inlet guide for a combustion drive compressor unit in this embodiment includes a guard ring 2, a guide vane set 3 and a guide vane set pressure ring 4, and it also includes an isolation cover 5, an inner casing 7, The casing 1 and the cooling system, the inner casing 7 is set on the isolation cover 5, the casing 1 is set on the outside of the inner casing 7 and connected to the inner casing 7 through the guide vane group 3, and the lower part of the guide vane group 3 is passed through the guide vane The group pressure ring 4 is press-fitted on the isolation cover 5, the upper part of the guide vane group 3 is press-fitted on the casing 1 through the retaining ring 2, and the cooling system is installed in the casing 1, the guide vane group 3, and the inner cover from top to bottom. On the casing 7 and the isolation cover 5; the casing 1 is a casing with a large mer...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 Description of this embodiment, the casing 1 of this embodiment includes a diffuser section 1-1, a gentle section 1-2 and a grommet installation section 1-3, and a diffuser section 1-1, a gentle section 1-2 and a grommet installation Segments 1-3 are sequentially connected from left to right and integrated. Such setting can not only reduce the axial dimension of the guide, but also facilitate the installation of the guide vane group and other equipment and parts, avoiding the sudden increase of the expansion angle of the diffuser section, causing other existing guide vanes to Inconvenience in design, manufacturing, craftsmanship, and assembly caused by the inability to install leaf groups and other components. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 1 To describe this embodiment, the included angle between the diffuser section 1 - 1 and the axis in this embodiment is 41°-43°. With such arrangement, the axial dimension of the guide is shortened under the premise of ensuring the connection between the gas generator turbine and the power turbine. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com