Subway covered top-down excavation structure and construction method thereof

A cover-excavation and subway technology, which is applied in the direction of foundation structure engineering, underwater structures, artificial islands, etc., and can solve problems affecting the strength of the roof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

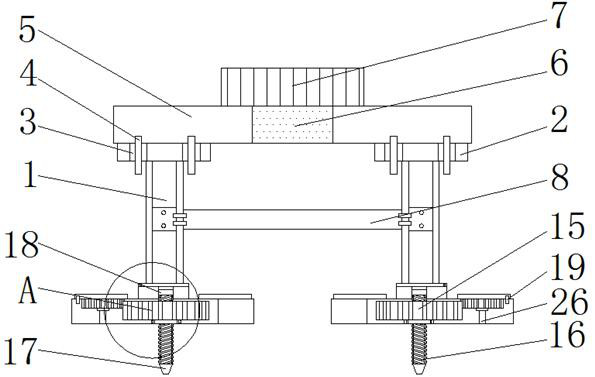

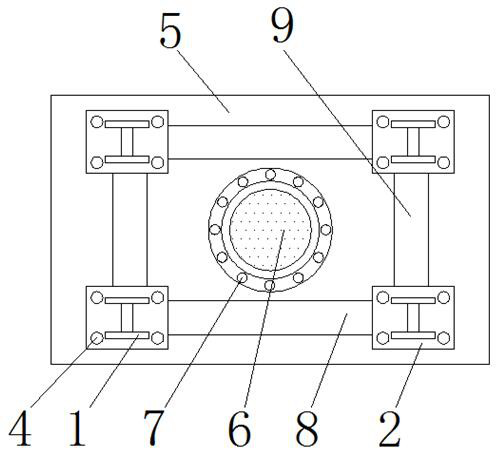

[0033] see Figure 1-5 , a subway cover excavation reverse structure, including support piles 1, the number of support piles 1 is four, and the number of support piles 1 is distributed around the sand outlet 6 at equal intervals, and the material of the support piles 1 is I-beam, through the set support Pile 1 increases the support point of the top plate 5, thereby increasing the strength of the top plate 5, the top of the support pile 1 is fixedly connected with the support plate 2, the surface of the support plate 2 is provided with fixing holes 3, and the number of the fixing holes 3 is four, and Distributed at equal intervals on the surface of the support plate 2, the support pile 1 is located at the center of the bottom of the support plate 2, the inner wall of the fixing hole 3 is threaded with a connector 4, and the connection between the support pile 1 and the top plate 5 is more stable through the provided connector 4 , so that the support pile 1 does not tilt during ...

Embodiment 2

[0036] A construction method for an excavated and inverted structure of a subway cover: specifically comprising the following steps:

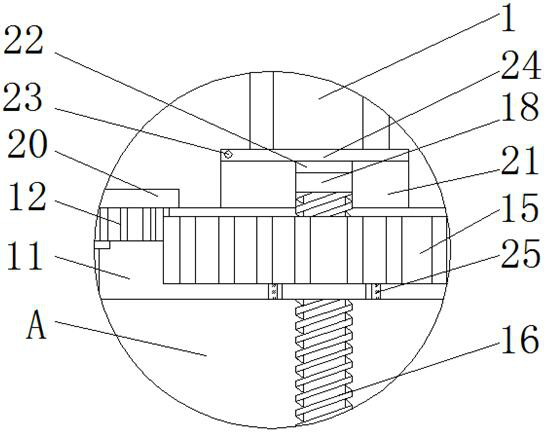

[0037] First, if Figure 1-Figure 5 As shown, prepare 4 support piles, install the chassis 10 at the bottom of the support pile 1, install the base 11 at the bottom of the chassis 10, install the fixed pile 26 at the bottom of the base 11, and install and connect the active bearing on the surface of the fixed pile 26 near the top. Gear 12, wherein the inner ring of driving gear 12 is installed and connected with fixed block 13, and the inner wall of fixed block 13 is installed with positioning stud 14, on the surface of driving gear 12, it is connected with rotating toothed disc 15 through meshing, wherein the inner ring of rotating toothed disc 15 Engage and install the rotating screw mandrel 16, install the rotating pile 17 at the bottom of the rotating screw mandrel 16, install the anti-off pile 18 at the top of the rotating screw mandrel 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com