Anti-wear and anti-static complexing agent for diesel oil

An antistatic agent, antistatic technology, applied in the field of diesel additives, diesel antiwear and antistatic composite agent, can solve the problems of low lubricity, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An anti-wear and anti-static composite agent for diesel oil, comprising the following components in mass percentage:

[0021] Diesel antiwear agent (linoleic acid mass percentage 55%, soybean oil mass percentage 32%, linolenic acid mass percentage 13%) 94%;

[0022] T1502 1%;

[0023] AEO3 5%.

[0024] After premixing the diesel antiwear agent and antistatic agent T1502, add it together with the solubilizing and dispersing agent AEO3 into the mixing tank, raise the temperature to 35-50°C, stir thoroughly for 30 minutes, and filter with a 70-mesh stainless steel filter to obtain the finished product .

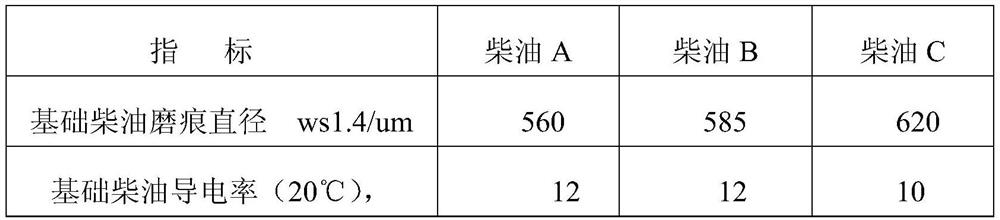

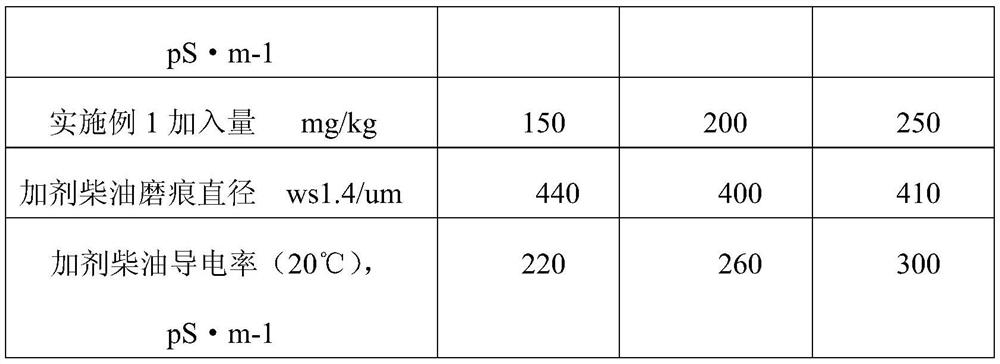

[0025] Comparative Test

[0026] Add different doses of the diesel anti-wear and antistatic composite agent of Example 1 of the present invention to three types of diesel oil in different periods, and test the wear scar diameter and electrical conductivity. The specific results are shown in Table 1 below.

[0027] Table 1

[0028]

[0029]

[0030] It can be se...

Embodiment 2

[0032] An anti-wear and anti-static composite agent for diesel oil, comprising the following components in mass percentage:

[0033] Diesel antiwear agent (linoleic acid mass percentage 55%, soybean oil mass percentage 32%, linolenic acid mass percentage 13%) 93%;

[0034] T1502 2%;

[0035] AEO3 5%.

[0036] After premixing the diesel antiwear agent and antistatic agent T1502, add it together with the solubilizing and dispersing agent AEO3 into the mixing tank, raise the temperature to 35-50°C, stir thoroughly for 30 minutes, and filter with a 70-mesh stainless steel filter to obtain the finished product .

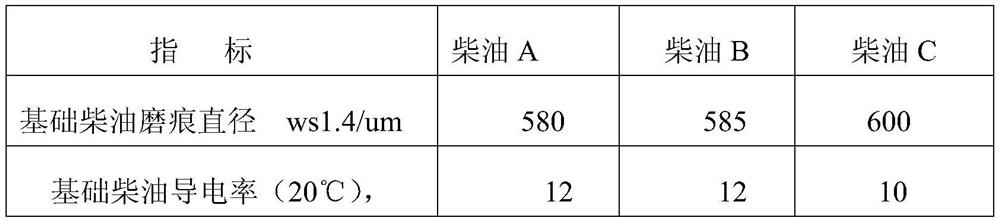

[0037] Comparative Test

[0038] Add different doses of the diesel anti-wear and antistatic composite agent of Example 2 of the present invention to three types of diesel oil in different periods, and test the wear scar diameter and electrical conductivity. The specific results are shown in Table 2 below.

[0039] Table 2

[0040]

[0041]

[0042] It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com