Device and method for treating nitric acid containing high-boiling-point organic matters

A processing device and processing method technology, applied in the chemical industry, can solve the problems of affecting availability and high content of high-boiling organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

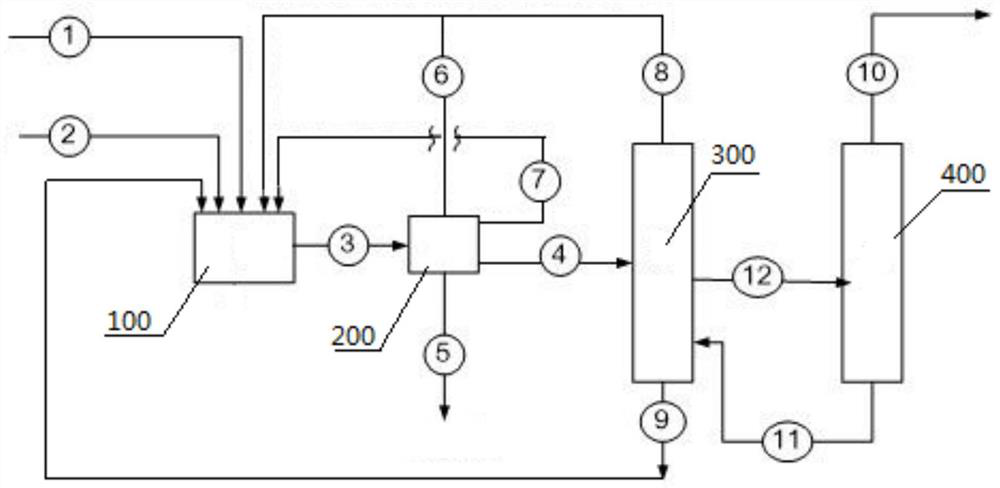

[0076]The outlet of the dilution kettle with a stirring structure in the dilution system 100 is connected to the dilution material inlet of the centrifuge in the solid-liquid separation system 200, and the diluted nitric acid outlet of the centrifuge in the solid-liquid separation system 200 is connected to the dilution of the distillation tower in the preliminary distillation system 300. The liquid inlet is connected, the high-boiling point organic matter outlet of the centrifuge in the solid-liquid separation system 200 is the organic matter extraction outlet, and the condenser outlet of the distillation tower in the preliminary distillation system 300 is the light component outlet. The first heavy component outlet (side gas phase outlet) of the distillation tower in the system 300 is connected with the concentrated nitric acid inlet of the rectification tower in the rectification system 400, and the second heavy component outlet of the distillation tower in the preliminary di...

Embodiment 2

[0080] The outlet of the dilution kettle with a stirring structure in the dilution system 100 is connected to the dilution material inlet of the filter in the solid-liquid separation system 200, and the diluted nitric acid outlet of the filter in the solid-liquid separation system 200 is connected to the dilution of the distillation tower in the preliminary distillation system 300. The liquid inlet is connected, the high-boiling point organic matter outlet of the filter in the solid-liquid separation system 200 is the organic matter extraction outlet, and the condenser outlet of the distillation tower in the preliminary distillation system 300 is the light component outlet. The first heavy component outlet (side gas phase outlet) of the distillation tower in the system 300 is connected with the concentrated nitric acid inlet of the rectification tower in the rectification system 400, and the second heavy component outlet of the distillation tower in the preliminary distillation ...

Embodiment 3

[0084] The outlet of the static pipeline mixer with mixing structure in the dilution system 100 is connected with the dilution material inlet of the centrifuge in the solid-liquid separation system 200, and the diluted nitric acid outlet of the centrifuge in the solid-liquid separation system 200 is connected with the distillation tower in the preliminary distillation system 300 The dilution liquid inlet is connected, the high-boiling organic matter outlet of the centrifuge in the solid-liquid separation system 200 is the organic matter extraction outlet, and the condenser outlet of the distillation tower in the preliminary distillation system 300 is the light component outlet connected to the static pipeline mixer in the dilution system 100 Inlet, the first heavy component outlet (side line gas phase outlet) of the distillation tower in the preliminary distillation system 300 is connected with the concentrated nitric acid inlet of the rectification tower in the rectification sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com