Atomizer

A technology for atomizers and atomizers, which is applied in the field of atomizers and can solve problems such as liquid leakage, mixed-flavor atomizers, and inconvenient adjustment of mist output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

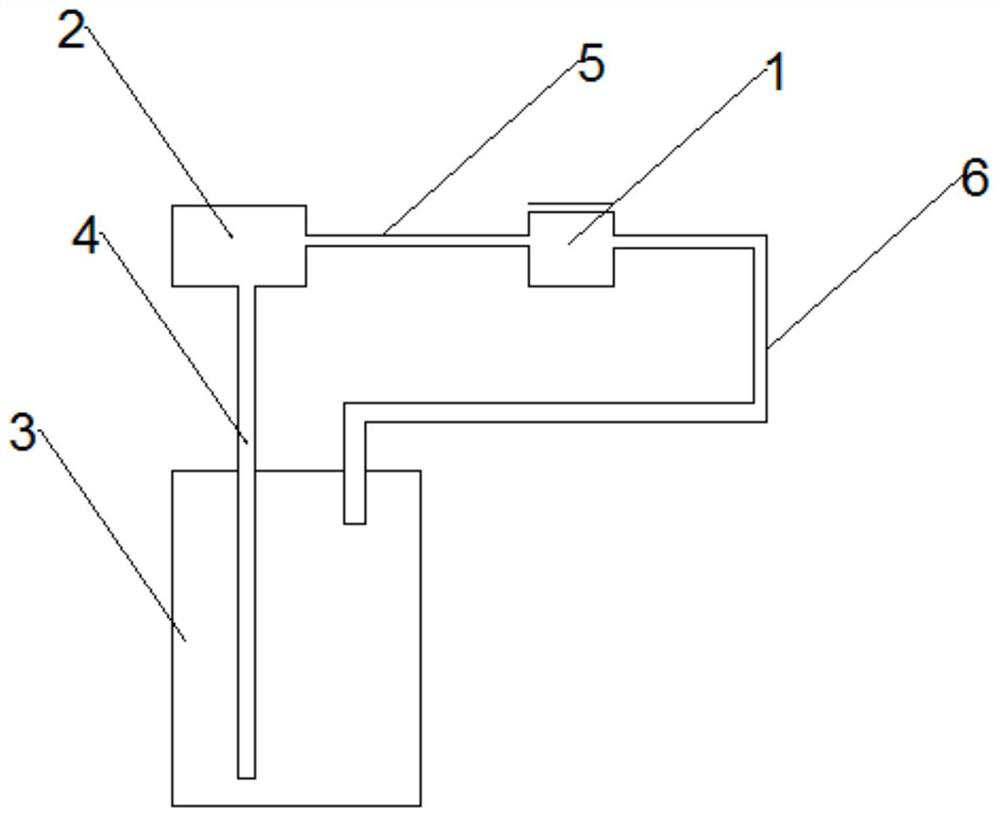

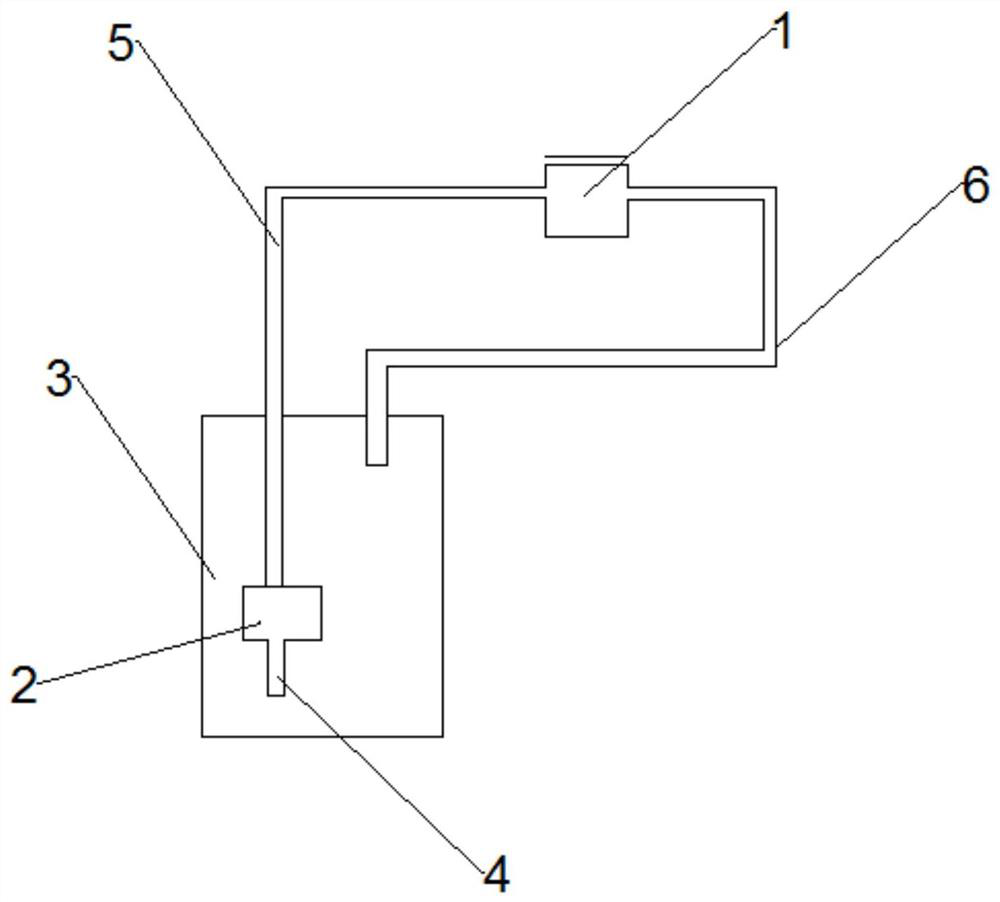

[0035] Specifically, such as Figure 1-9 As shown, an atomizer includes a liquid bottle 3, a power assembly 2 and an atomization system 1, and the liquid bottle 3, the power assembly 2 and the atomization system 2 are connected through pipelines to form a circulation system, so The power assembly 2 can deliver the liquid in the liquid bottle 3 to the atomizing system 1 in a liquid or foam state, and the atomizing system 1 can atomize the liquid entering it. The atomizing system 1 The outlet of the outlet is connected with the liquid bottle 3, so that the liquid in the atomization system 1 can flow back into the liquid bottle 3, and the gas phase in the atomization system 1 and the liquid in the liquid bottle 3 The gas phases can communicate with each other.

[0036] Preferably, the atomization system 2 is located above the liquid bottle 3 .

[0037] Further, the liquid bottle 3 is connected to the power assembly 2 or the atomization system 1 through the liquid inlet pipe 4, ...

Embodiment 2

[0049] Such as figure 1 As shown, an atomizer includes a liquid bottle 3, a power assembly 2 and an atomization system 1, and the liquid bottle 3, the power assembly 2 and the atomization system 2 are connected through pipelines to form a circulation system, so The power assembly 2 can deliver the liquid in the liquid bottle 3 to the atomizing system 1, and the atomizing system 1 can atomize the liquid entering it.

[0050] Further, the liquid bottle 3 communicates with the power assembly 2 through a liquid inlet pipe 4, one end of the liquid inlet pipe 4 communicates with the liquid inlet of the power assembly 2, and the liquid inlet pipe 4 The other end extends below the liquid level in the liquid bottle 3; the liquid outlet of the power assembly 2 communicates with the liquid inlet of the atomization system 1 through a connecting pipe 5; the atomization system 1 The discharge port of the nozzle is connected with the liquid bottle 3 through the return pipe 6 , one end of th...

Embodiment 3

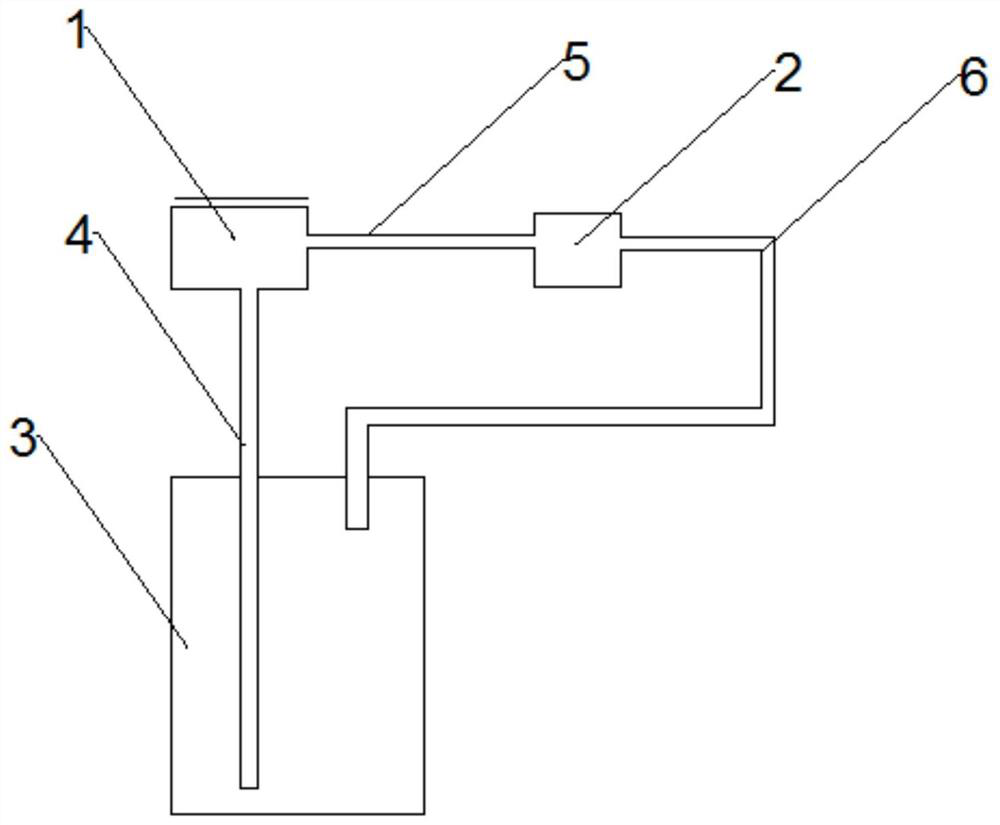

[0054] Such as figure 2 As shown, an atomizer includes a liquid bottle 3, a power assembly 2 and an atomization system 1, and the liquid bottle 3, the power assembly 2 and the atomization system 2 are connected through pipelines to form a circulation system, so The power assembly 2 can deliver the liquid in the liquid bottle 3 to the atomizing system 1, and the atomizing system 1 can atomize the liquid entering it.

[0055] Further, the liquid bottle 3 communicates with the atomization system 1 through a liquid inlet pipe 4, one end of the liquid inlet pipe 4 is connected to the liquid inlet of the atomization system 1, and the inlet The other end of the liquid pipe 4 extends below the liquid level in the liquid bottle 3; the outlet of the atomization system 1 and the liquid inlet of the power assembly 2 are connected through a connecting pipe 5; the power The liquid outlet of the assembly 2 communicates with the liquid bottle 3 through a return pipe 6 , one end of the retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com