Paper substrate radio frequency antenna and production method thereof

A paper substrate, radio frequency antenna technology, applied in the direction of antenna, antenna parts, antenna support/installation device, etc., can solve the problems of poor performance, long-term environmental pollution, high cost, reduce production costs, reduce pollution, The effect of easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Production of UHF copper antenna on paper substrate:

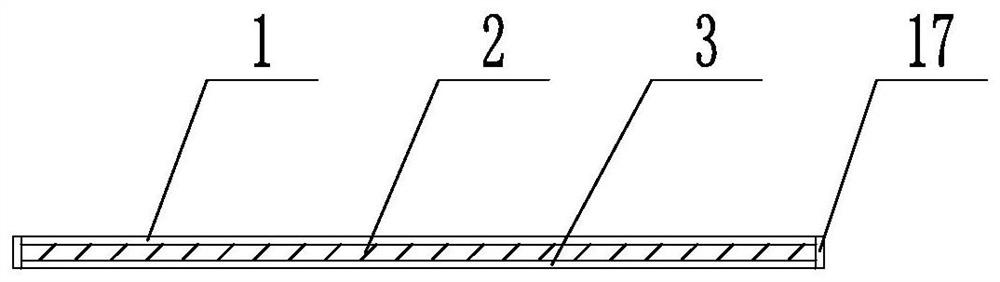

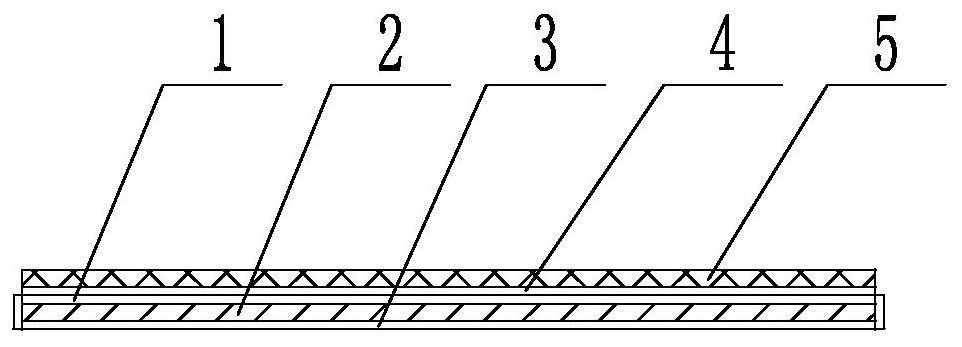

[0053] (1) Coating: Choose to use 80 g / square meter coiled offset paper. On the laminating equipment, select high-pressure polyethylene material, and pass the high-pressure polyethylene particles through the screw propeller, pushing them while heating, and melting them into liquid polyethylene. , through the coating head, the molten polyethylene is coated on the surface of the roll paper, and under the rotation and cooling of the cooling roller, the coated polyethylene is instantly solidified into a coating layer on the surface of the paper substrate. The two sides of the offset paper are coated with film respectively. refer to figure 1 shown.

[0054] (2) End face waterproofing: edge sealing oil realizes end face waterproofing. The offset paper treated with film coating needs to be cut and edge treated according to needs, and then on the dry coating machine, use a felt wheel to apply the heated silicone oil to th...

Embodiment 2

[0060] Production of high-frequency aluminum antennas on paper substrates:

[0061] (1) Coating: choose to use 65 g / square meter glassine base paper, and select high-pressure polyethylene material on the coating equipment, and pass the high-pressure polyethylene particles through the screw propeller, pushing them while heating, and melting them into liquid polythene. Ethylene, through the coating head, coats molten polyethylene on the surface of the roll paper, and under the cooling of the cooling roller, the coated polyethylene is instantly solidified into a coating layer on the surface of the paper substrate. The two sides of glassine base paper are coated with film respectively. refer to figure 1 shown.

[0062] (2) End face waterproofing: The edge sealing oil realizes the end face waterproofing. The coated glassine base paper needs to be cut and edged according to the needs, and then on the dry coating machine, use the felt wheel to apply the heated silicone oil to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com