Low-voltage electrostriction actuator based on PVC gel driving

A technology of actuators and low-voltage electricity, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric devices/electrostrictive devices, circuits, etc., can solve problems such as layer-to-layer separation, driver failure, etc. Achieve the effect of reducing the overall size, reducing the driving voltage, and reducing the driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

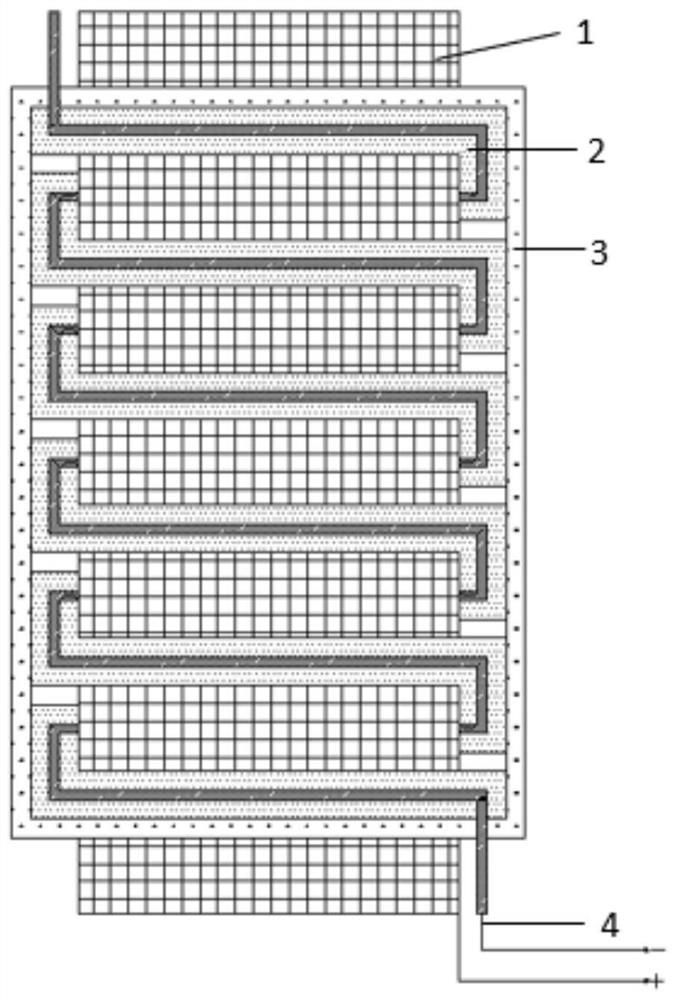

[0043] The preparation material of the anode 1 is a conductive mesh material, such as a metal mesh, a metal-plated plastic mesh, a carbon nanotube (CNT) film with a mesh structure, a graphene film or a polymer doped with a conductive material. mesh membrane etc.

[0044] The shell 3 is made of flexible insulating materials, such as silica gel, TPU and flexible insulating fabric, etc., and the manufacturing methods can be casting, insulating fiber weaving, 3D printing, etc.

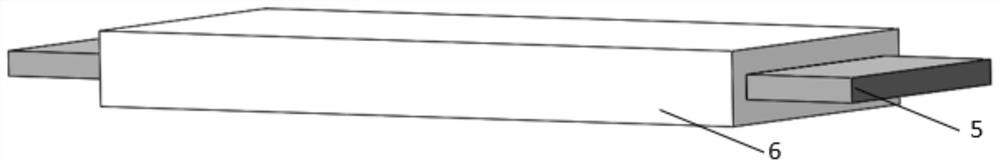

[0045] see figure 2 , PVC gel-cathode integrated membrane 2 is composed of ultra-thin PVC gel film 6 and cathode 5 to form a sandwich or myelin fiber structure, cathode 5 is wrapped by PVC gel film 6, and the thickness of PVC gel film 6 is not more than 100 μm , and the corresponding thickness of the anode 1 is not more than 100 μm.

[0046] The thickness of the cathode 5 is not more than 20 μm, and the preparation material of the cathode 5 is a flexible conductive material, such as metal double-zero fo...

Embodiment 1

[0063] First prepare PVC gel film, use PVC solid powder with a polymerization degree of 4000, mix with plasticizer dibutyl adipate (DBA) in a mass ratio of 1:4, and dissolve it in solvent tetrahydrofuran (THF) after mixing , the mass ratio of the mixture to tetrahydrofuran was 1:3 to obtain a PVC plasticizing solution.

[0064] Adjust the blade slit of the coating machine to 100 μm, set the working speed of the coating machine to 14 mm / s, and the working temperature to 20° C. Pour the configured PVC plasticizing solution on the coater and start the coater. After the THF was completely volatilized, a PVC gel film 6 with a thickness of 100 μm was obtained.

[0065] see figure 1 , the cathode material is aluminum foil 5 with a thickness of 7 μm. With aluminum foil 5 as the core layer and PVC gel film as the outer layer, the two are stacked in a "sandwich" structure, and then the whole is laser cut to obtain a rectangular PVC gel-cathode integrated film 2 with a width of 10mm. ...

Embodiment 2

[0070] First prepare PVC gel film, use PVC solid powder with a polymerization degree of 3000, mix with plasticizer dibutyl adipate (DBA) in a mass ratio of 1:3, and dissolve it in solvent tetrahydrofuran (THF) after mixing , the mass ratio of the mixture to tetrahydrofuran was 1:4 to obtain a PVC solution.

[0071] Divide the working process of the homogenizer into seven steps, accelerate to 1500rpm step by step, and then decelerate step by step. Start the homogenizer, add the PVC plasticizing solution into the homogenizer, and obtain a PVC gel film 6 with a thickness of 10 μm after the homogenizer is finished.

[0072] see figure 1 , The cathode material is PVC gel film doped with carbon powder with a thickness of 10 μm. The PVC gel film doped with carbon powder is used as the core layer, and the PVC gel film 6 is the outer layer. The two are stacked in a "sandwich" structure, and then the whole body is laser cut to obtain a PVC gel film with a shape similar to "candied haw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com