A method for measuring gas-bearing porosity of shale

A measurement method and porosity technology, applied in the field of shale gas reserve prediction, can solve the problems of low shale porosity, small pore volume, system error, etc., and achieve accurate measurement results, accurate measurement of gas-bearing pore volume, and process The effect of step simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

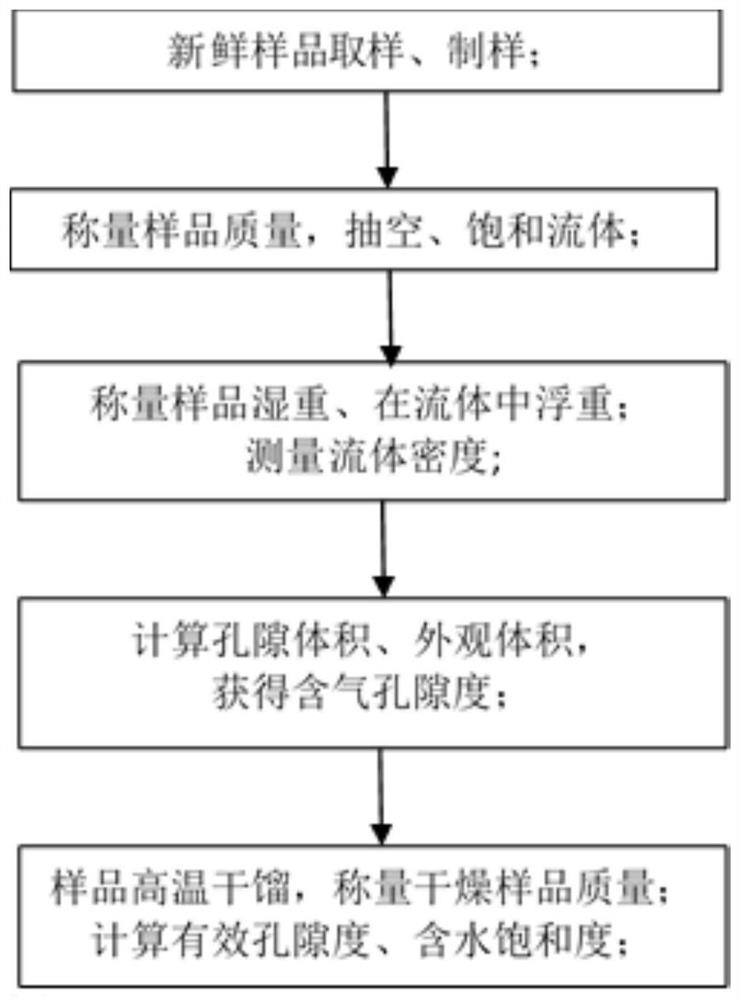

[0023] Such as figure 1 Shown, a kind of shale gas-bearing porosity measuring method comprises the following steps:

[0024] 1) Sample preparation: Take shale without water soaking from the middle of the full-diameter core in time, cut it into a rectangle, specify the bedding direction according to the requirements, the mass is not less than 40g, and number the sample; prepare the formation salinity brine (density ρ), Or standard brine with a salinity of 50,000 for standby;

[0025] 2) Weigh the sample mass M on a one-ten-thousandth balance with the cut rectangular rock core 1 ; Vacuumize the rectangular rock core sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com