An energy-saving air separation cooling system and method

A cooling system and energy-saving technology, applied in the field of intelligent air separation equipment, can solve the problems of excessive input of liquid nitrogen, inaccurate control of cooling capacity, and large energy loss, so as to reduce production costs, avoid unsalable products, and reduce unsatisfactory The effect of the necessary loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are used to further describe the present invention in detail, but the examples do not limit the present invention in any form. Unless otherwise specified, the reagents, methods and equipment used in the present invention are conventional reagents, methods and equipment in the technical field, But it does not limit the present invention in any form.

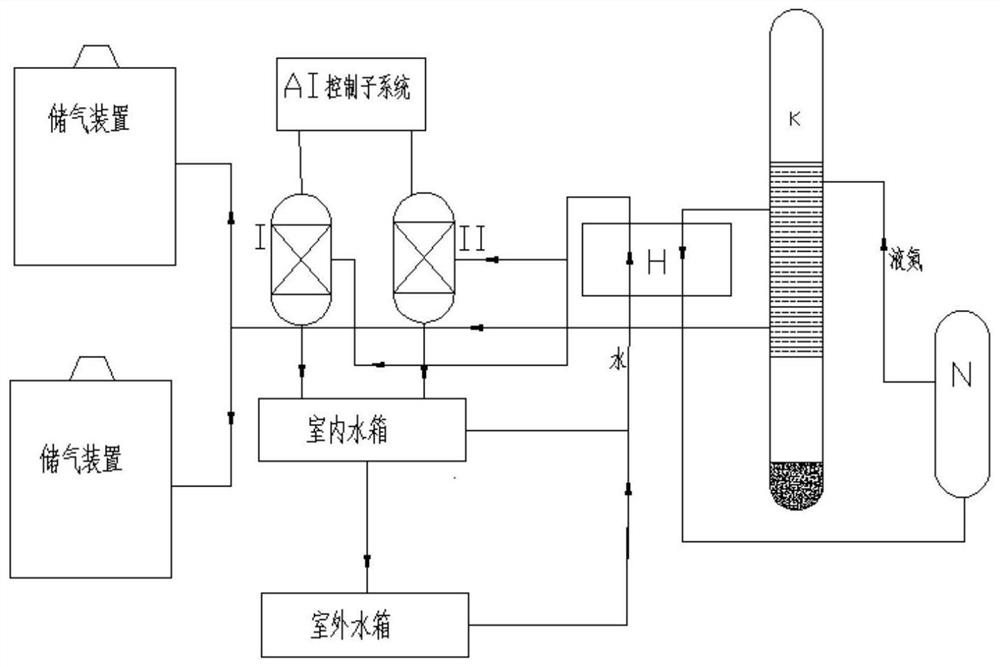

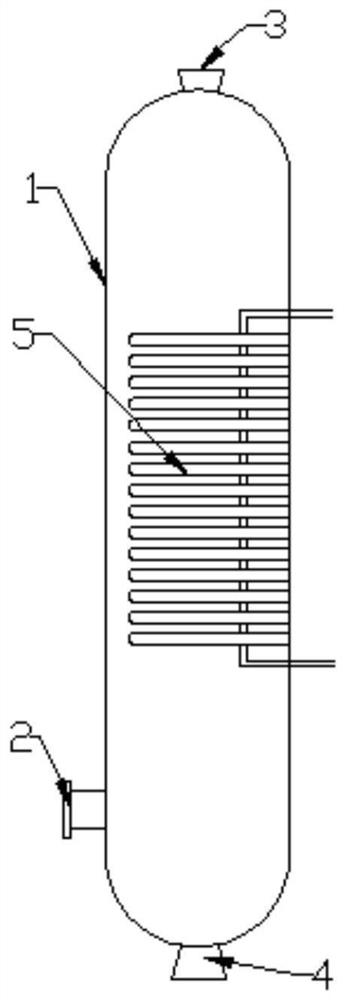

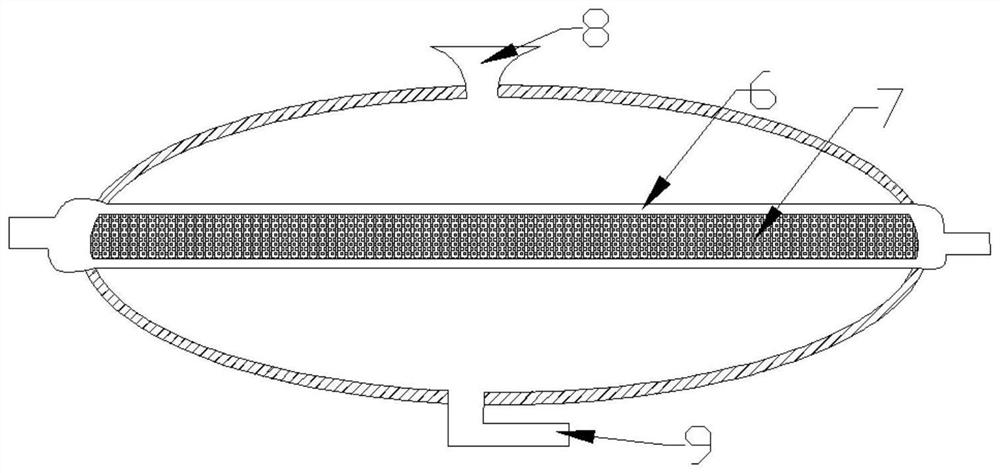

[0028] The embodiment of the invention discloses an energy-saving air separation cooling system, such as Figure 1-4 As shown, the energy-saving air separation cooling system of the present invention includes an AI control subsystem, a molecular sieve system, a cooling rectification tower, a liquid nitrogen storage device, a cooling capacity exchange subsystem, an indoor water tank, a heat exchanger and a gas storage device, specifically , figure 1 Among them, I and II are molecular sieve systems, and the molecular sieve system includes two molecular sieve devices, one is an adsorption molecular siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com