Extremely-simple type hydraulic rotary buffer

A technology of hydraulic rotation and buffer, applied in the direction of liquid resistance brakes, brake types, seat or cover for toilets, etc., can solve the problems that damping oil cannot pass through or is slow, increase assembly cost, high manufacturing cost and assembly cost, etc. Achieve the effect of simple and reliable structure and function, stable damping oil pressure, and easy production and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 (flexible oil wing without cavity, single concave surface).

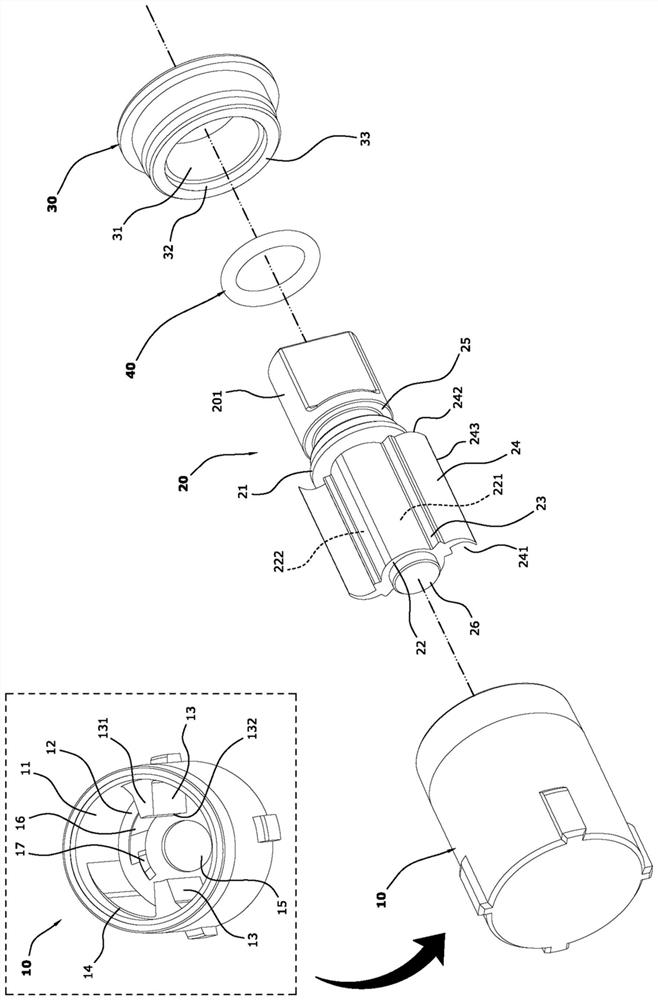

[0037] Such as figure 1 and figure 2 A minimalist hydraulic rotary buffer shown is only composed of a shaft sleeve 10 , a rotating shaft 20 , a gland 30 and a sealing ring 40 .

[0038] Such as Figure 1 to Figure 5 As shown, the shaft sleeve 10 of the present invention is integrally injection molded. The shaft sleeve 10 has an oil chamber 11, and two partition ribs 13 connected to the bottom surface 12 of the chamber are symmetrically arranged on the wall of the oil chamber 11. The axial top ends of the partition ribs 13 are partition ribs The top surface 131 of the rib 13 is an oil-separating surface 132 at the radial end of the rib 13; two arc-shaped platform sections 14 are arranged on the oil chamber 11 wall on the symmetrical side of the two ribs 13, and the bottom surface 12 of the oil chamber 11 It has a central hole 15, and the bottom surface 12 of the cavity is provided with a fast oi...

Embodiment 2

[0055] Embodiment two (the oil wing has cavity, double concave surface).

[0056] Such as Figure 9 ~ Figure 13As shown, the difference between the present embodiment and the first embodiment is that the oil deflection wing 24 of the present embodiment has two concave surfaces 241 for deflecting the oil, a top edge surface 242 that is in contact with the inner end surface 33, and an arc-shaped platform section 14 Elastic press-contact fits the wing end 243, and the oil wing 24 also has a cavity 244 to increase its flexural deformation elasticity; in this way, the rotating shaft 20 is inserted into the sleeve 10, and the concave surface 241 of the oil wing 24 is no longer identified Whether or not it faces the arc-shaped platform section 14, the assembly efficiency is improved; and the cavity 244 is added to the oil wing 24, which can increase the elasticity and elastic sensitivity of the oil wing 24, and also increase the speed of its shape recovery. Other structures, working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com