A fast-assembled tunnel ventilation partition structure

A tunnel ventilation and prefabricated technology, applied in mine/tunnel ventilation, safety devices, mining devices, etc., can solve the problems of high resistance, easy damage, high air leakage rate along the way, and achieve less impact, easy installation, and long-term The effect of distance ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to more clearly understand the above objects, features and advantages of the present disclosure, the solutions of the present disclosure will be further described below. It should be noted that, in the case of no conflict, the embodiments of the present disclosure and the features in the embodiments can be combined with each other.

[0025] In the following description, many specific details are set forth in order to fully understand the present disclosure, but the present disclosure can also be implemented in other ways than described here; obviously, the embodiments in the description are only some of the embodiments of the present disclosure, and Not all examples.

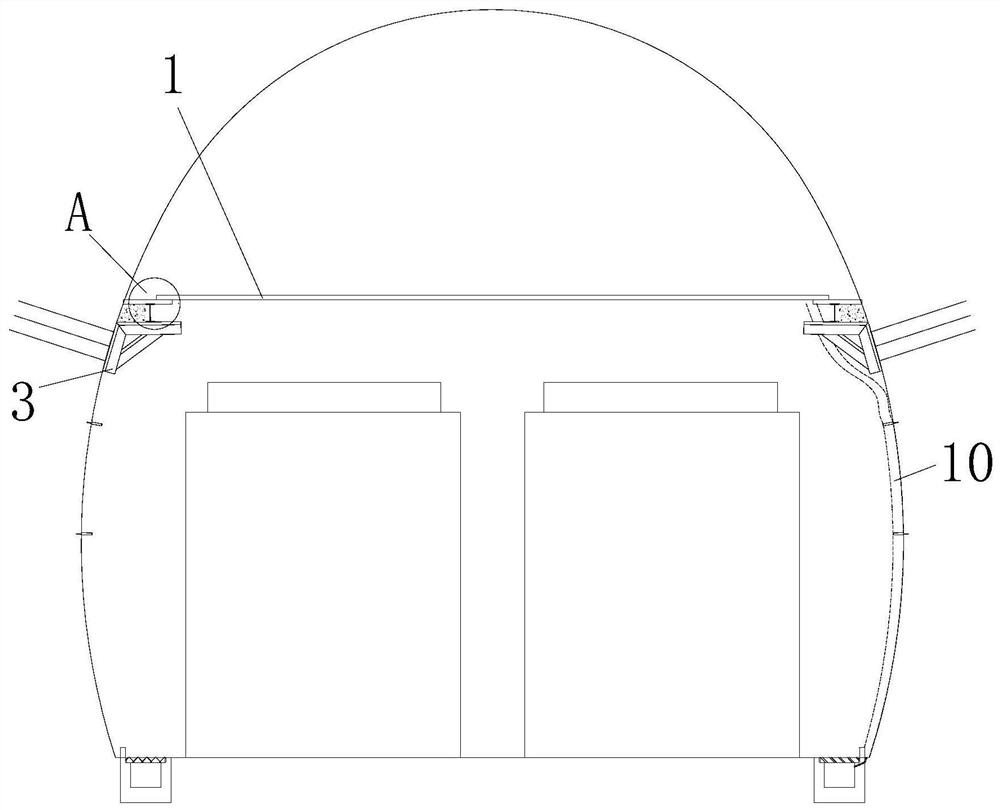

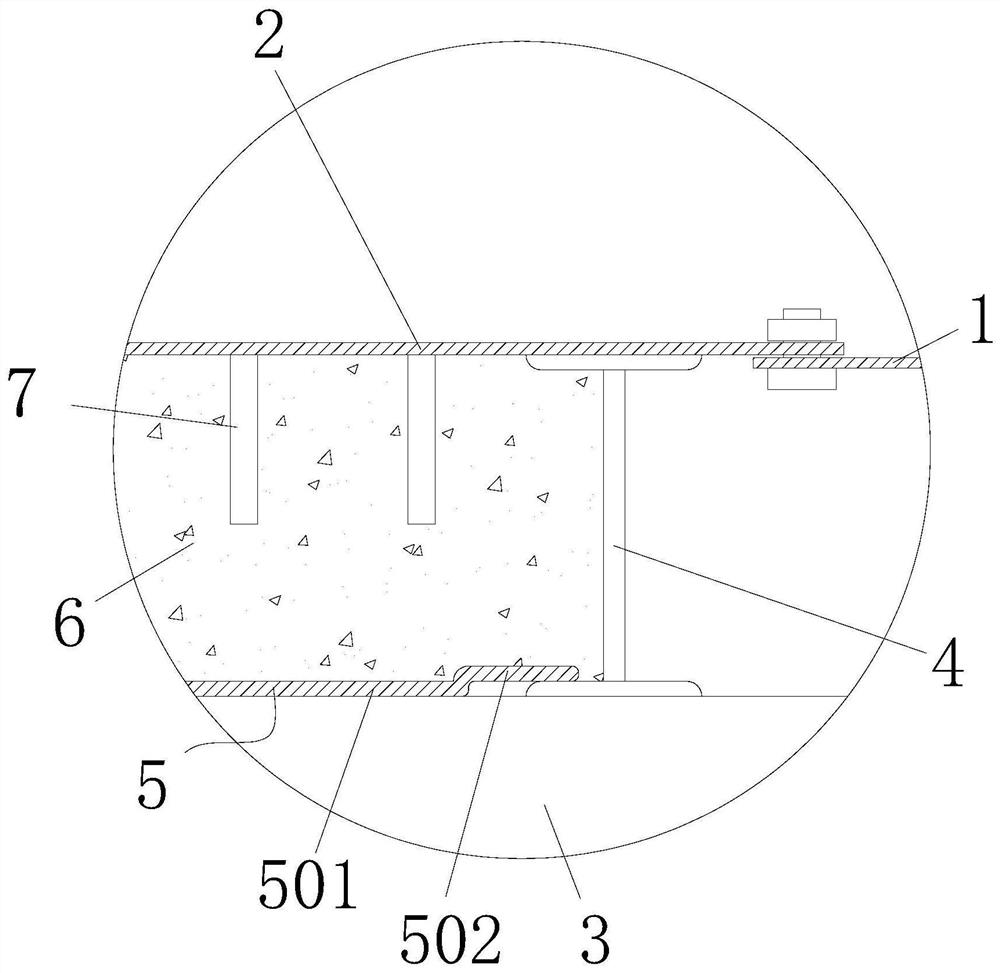

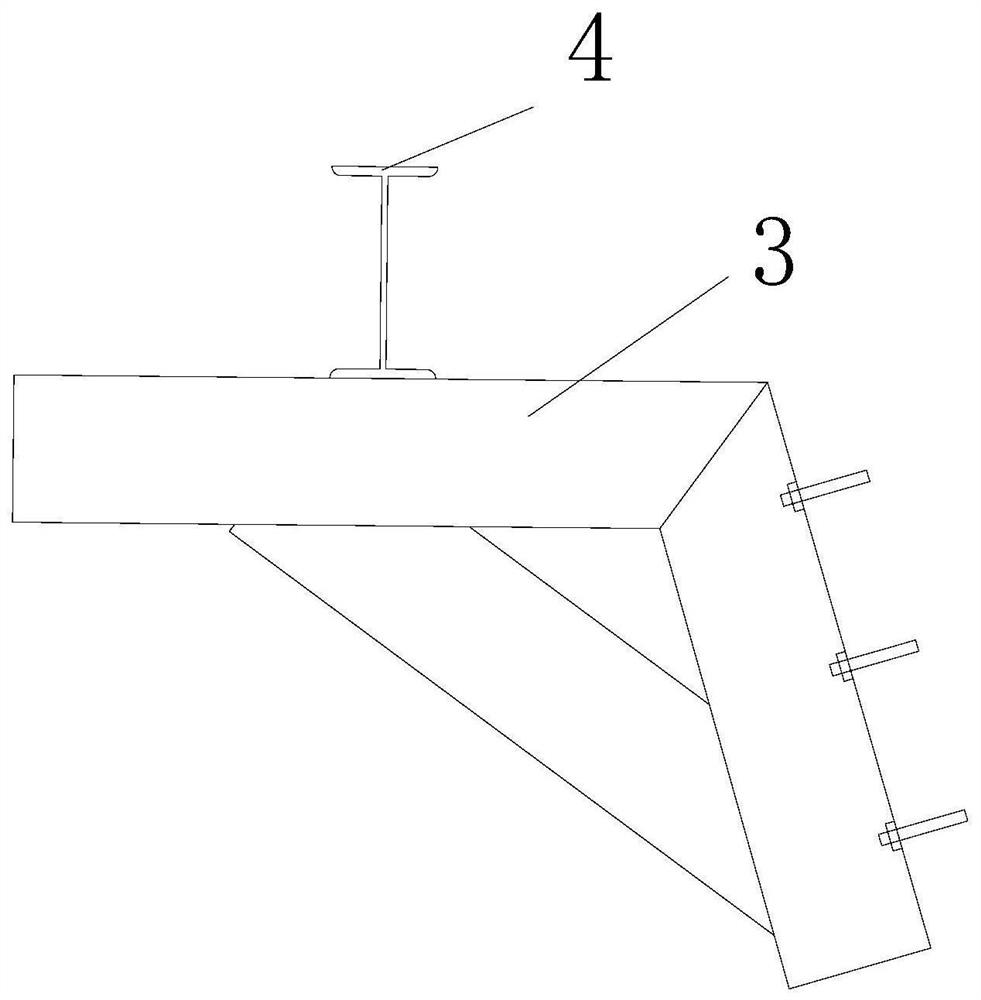

[0026] In some examples, see figure 1 , the present disclosure provides a quick-assembled tunnel ventilation partition structure, including a partition member arranged longitudinally along the inclined shaft of the tunnel, a ventilation channel is formed between the partition member and the vaul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com