A kind of total heat exchange graphene paper film

A technology of graphene paper and total heat exchange, which is applied in the direction of papermaking, paper, paper machines, etc., and can solve the problems of reducing air permeability

Active Publication Date: 2022-06-03

潍坊杰高非织材料科技有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in terms of improving sensible heat exchange efficiency and reducing air permeability, the patent application does not involve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

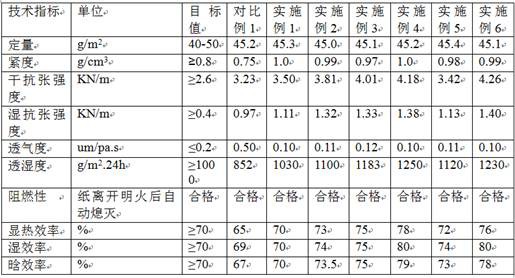

Embodiment 1

Embodiment 2

Embodiment 3

[0060] The phosphorus-based flame retardant is a phosphorus-containing compound;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a kind of total heat exchange graphene paper film, raw materials include plant fiber slurry, high molecular polymer, flame retardant, antibacterial agent and graphene water-based slurry; the plant fiber slurry is imported coniferous wood pulp or A mixed slurry of imported softwood pulp and hardwood pulp; the graphene water-based slurry: the active ingredient content is 5-15%, and the viscosity is 1000-6000mpa.s; raw materials also include polyacrylamide, cationic starch, carboxymethyl At least one of the base cellulose sodium, the addition amount is 2-5% relative to the dry fiber content. The raw material also includes at least one of polyacrylamide, cationic starch, and sodium carboxymethyl cellulose, and the added amount is 2-5% relative to the dry fiber amount. The mass ratio of the high molecular polymer to the flame retardant is 1:4-10. The air permeability of the total heat exchange graphene paper film of the present invention is ≤0.2μm / Pa·s, and the moisture permeability is ≥1000g / m 2 24h.

Description

A kind of full heat exchange graphene paper membrane technical field The invention belongs to special paper technical field, relate in particular to a kind of full heat exchange graphene paper film. Background technique Air conditioner works indoors in a building, if airtight is not ventilated, and indoor and outdoor ventilation is not performed for a long time, the air will become It gets dirty, so it needs to be constantly exchanged with fresh outdoor air. The total heat exchanger is the key to the energy exchange of the fresh air system. The key factor, the use of total heat exchanger to complete the energy exchange between indoor and outdoor air is a commonly used method at home and abroad. The effect influencing factors of total heat exchanger mainly include the following: Sensible heat: the heat absorbed or released along with the temperature change of moist air, utilizes fresh air, exhaust air temperature difference to recover sensible heat. heat. [0005] ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D21G1/00D21H17/00D21H17/06D21H17/29D21H21/16D21H23/34

CPCD21H17/00D21H17/29D21H17/06D21H21/16D21H23/34D21G1/00Y02P20/10

Inventor 初杰王光民于东兴李雪冰

Owner 潍坊杰高非织材料科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com