Hot galvanizing noise reduction and edge thickness control baffle, device and method

A technology of hot-dip galvanizing and noise reduction plate, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of ineffective reduction and great impact on the working environment, and reduce the harm of occupational diseases , The effect of improving product quality and saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

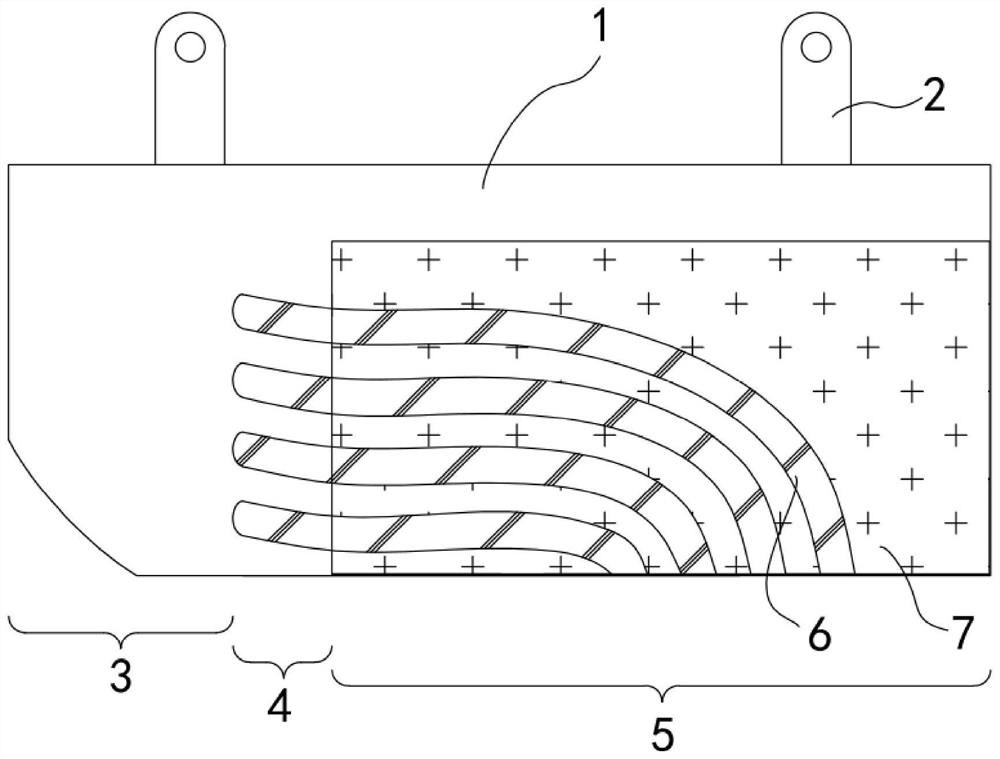

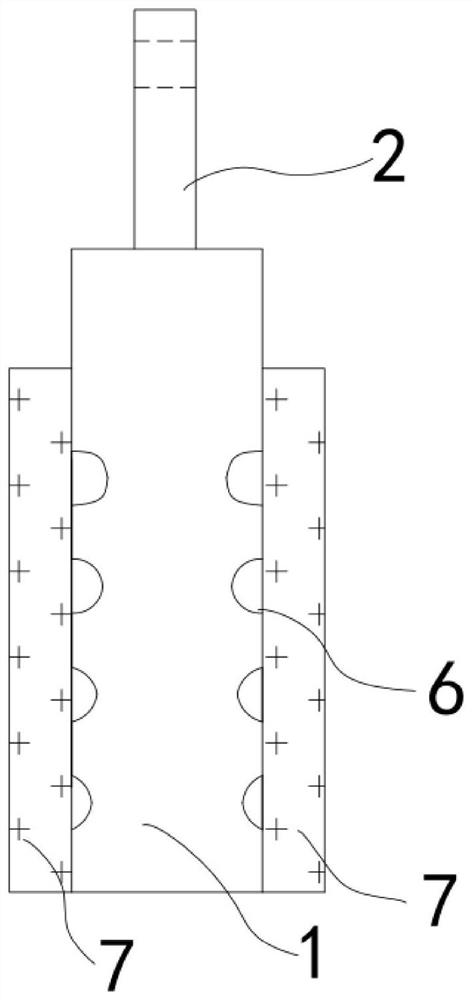

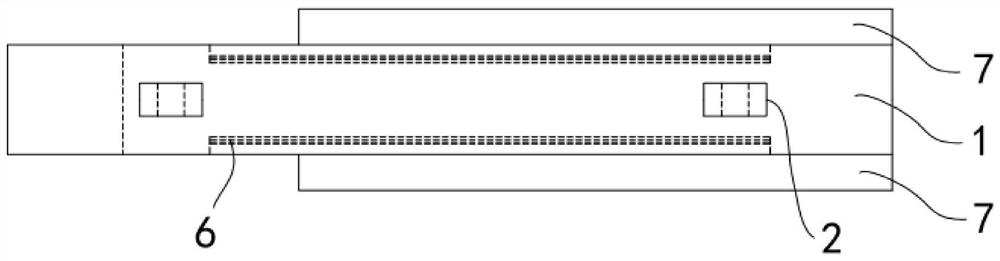

[0029] see Figure 1-Figure 4 A baffle for hot-dip galvanizing noise reduction and side thickness control, comprising a baffle 1, a mounting block 2 arranged on the top of the baffle and a noise reduction plate 7, the baffle for hot-dip galvanizing noise reduction and side thickness control includes working Area 3, transition area 4, noise reduction area 5, the lower end of the working area 3 away from transition area 4 is arc-shaped, transition area 4 and noise reduction area 5 are provided with airflow diversion groove 6, and noise reduction area 5 is also provided with a noise reduction area. noise board 7;

[0030] It should be pointed out that:

[0031] 1. The b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com