Maintenance-free tire rubber material and preparation method thereof

A maintenance-free, tire technology, applied in special tires, tire parts, rolling resistance optimization, etc., can solve the problems of poor grip, heavy solid tires, slow air leakage, etc., to achieve economical and adaptability, compression The effect of low heat generation and reduction of hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

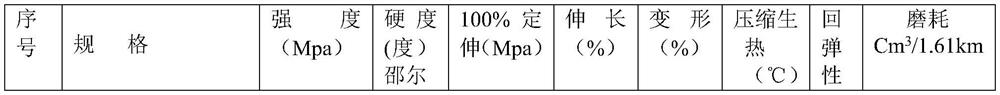

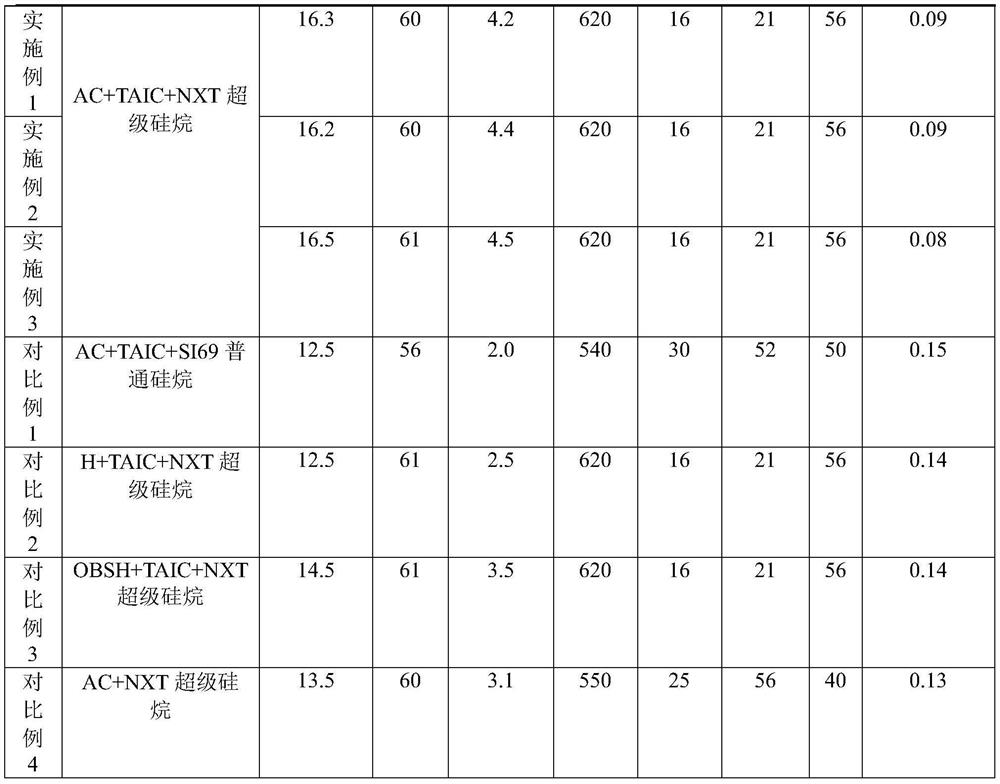

Examples

Embodiment 1

[0022] Prepare raw materials according to the following parts by weight:

[0023] Natural rubber SVR3L: 30 parts;

[0024] Three yuan ethylene propylene rubber EPDM4045: 70 parts;

[0025] Carbon black N234: 15 parts;

[0026] White carbon black: 40;

[0028] Stearic acid: 1.5 parts;

[0029] Antiaging agent 4020: 1 part;

[0030] Accelerator CZ: 0.6 parts;

[0031] Sulfur: 0.85 parts;

[0032] Foaming agent AC: 2.5 parts;

[0033] Foaming aid TAIC: 1.1 parts;

[0034] NXT Super Silane: 3.2 parts (8% of silica).

[0035] Mix EPDM rubber and natural rubber with carbon black in an internal mixer for 240 seconds to make carbon black masterbatch, and park for more than 2 hours. After masticating the carbon black masterbatch in the internal mixer for 30 seconds, add white carbon black, zinc oxide, stearic acid, anti-aging agent and super silane, and knead in the internal mixer for 120 seconds to make a mixed rubber. Park the rubber mixture...

Embodiment 2

[0037] Prepare raw materials according to the following parts by weight:

[0038] Natural rubber SVR3L: 70 parts;

[0039] EPDM4045: 30 parts;

[0040] Carbon black N234: 15 parts;

[0041] White carbon black: 40 parts

[0042] Zinc oxide: 2.5 parts;

[0043] Stearic acid: 1.5 parts;

[0044] Antiaging agent 4020: 1 part;

[0045] Accelerator CZ: 0.6 parts;

[0046] Sulfur: 0.85 parts;

[0047] Foaming agent AC: 2.5 parts;

[0048] TAIC: 1.5 copies;

[0049] NXT Super Silane: 2.0 parts (5% of silica);

[0050] The preparation method is the same as in Example 1 to obtain a maintenance-free tire compound.

Embodiment 3

[0052] Prepare raw materials according to the following parts by weight:

[0053] Natural rubber SVR3L: 60 parts;

[0054] EPDM4045: 40 parts;

[0055] Carbon black N234: 15 parts;

[0056] White carbon black: 40 parts

[0057] Zinc oxide: 3 parts;

[0058] Stearic acid: 1.5 parts;

[0059] Antiaging agent 4020: 1.4 parts; Antiaging agent RD: 0.1 parts;

[0060] Accelerator CZ: 0.5 parts; Accelerator NS: 0.1 parts;

[0061] Sulfur: 0.8 parts;

[0062] Foaming agent AC: 2.5 parts;

[0063] TAIC: 1.2 copies;

[0064] NXT Super Silane: 2.4 parts (6% of silica).

[0065] The preparation method is the same as in Example 1 to obtain a maintenance-free tire compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com