Underground flowing type curing kiln system for precast concrete parts

A prefabricated concrete and curing kiln technology, which is applied in the direction of manufacturing tools, lifting devices, auxiliary molding equipment, etc., can solve the problems of affecting production efficiency, occupying the space of the assembly line, and the curing kiln cannot carry out mobile production operations, so as to save the plane area, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

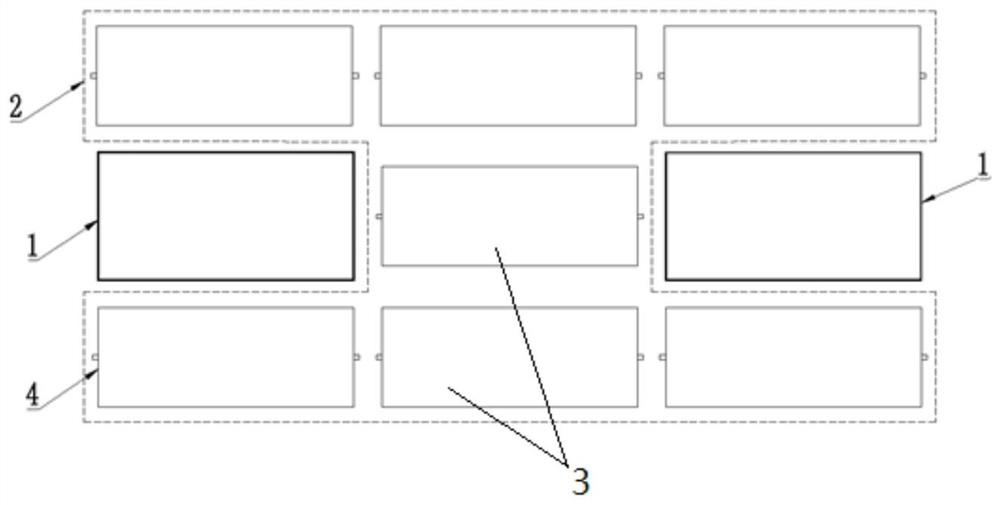

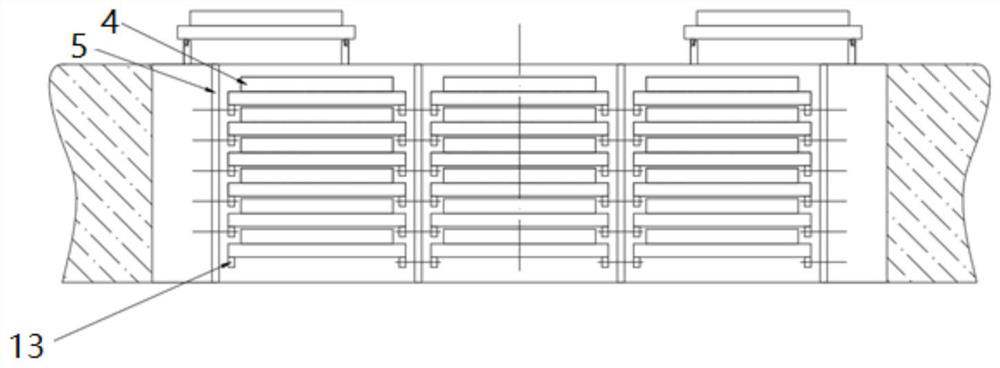

[0020] Such as Figure 1~5 An underground flowing curing kiln system for prefabricated concrete components is shown, including component access equipment 1 and underground curing kiln 2;

[0021] The underground curing kiln 2 includes a plurality of curing units 3 arranged in M rows and N columns, and each curing unit 3 includes multiple layers of independent curing stations 4; wherein, M and N are greater than or equal to 1 respectively. There are at least two component access devices 1, which are respectively installed at the entrance and exit of the underground curing kiln 2 to realize the position switching of the concrete component 11 between the surface assembly line and the underground curing kiln 2. Such as figure 1 As shown, M and N of this embodiment are 3 respectively, and the second row of the first column and the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com