Curved flexible intelligent grinding robot based on Internet

An Internet and robot technology, applied in the field of robots, can solve problems such as affecting the breathing of workers, unable to recycle wood chips, affecting processing accuracy, etc., to achieve the effect of improving the yield rate, simple structure, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

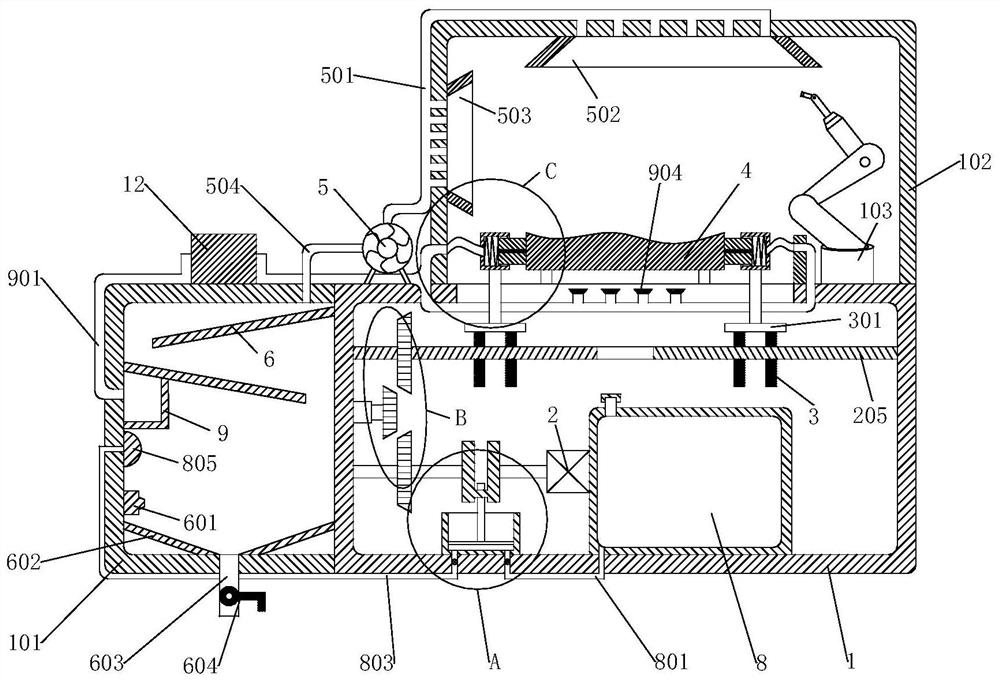

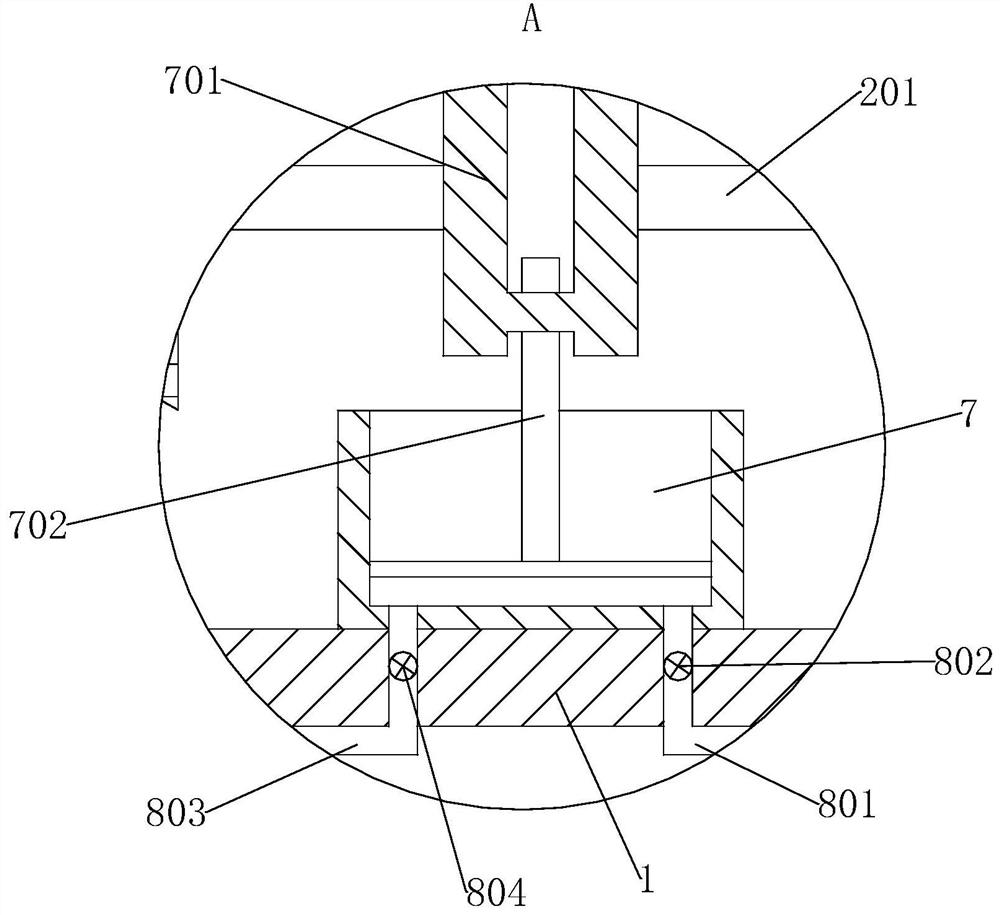

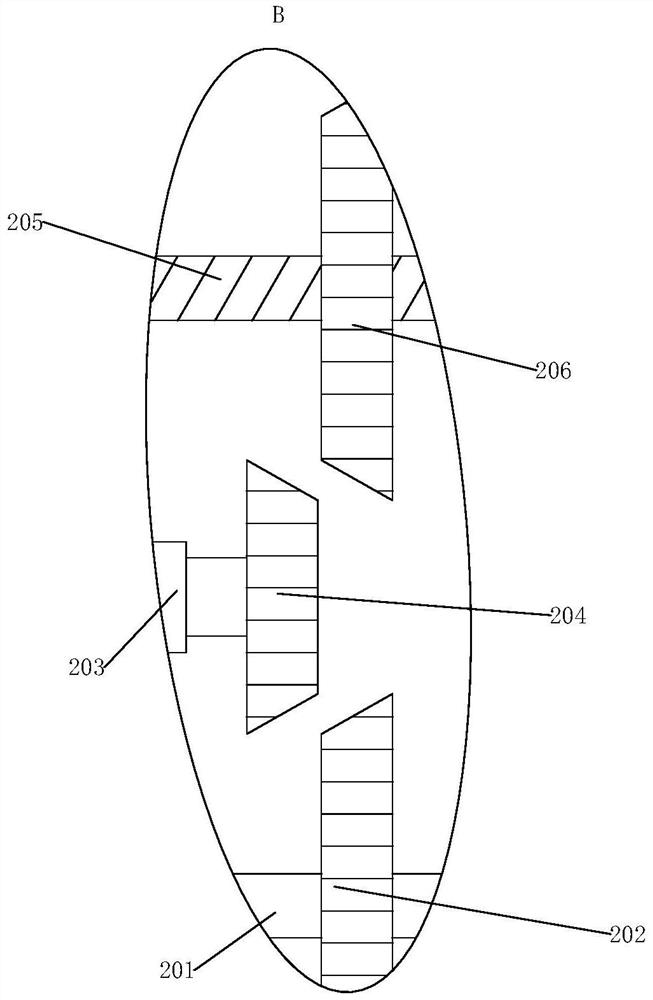

[0029] refer to Figure 1-7, a curved surface flexible intelligent grinding robot based on the Internet, including a first box body 1, a second box body 101, a protective cover 102, a polishing arm 103 and a wood body 4, the polishing arm 103 is located on the top of the first box body 1, and the second A tank 1 is provided with a water tank 8, the side wall of the water tank 8 is provided with a motor 2, the output end of the motor 2 is connected with a rotating shaft 201, and the inner wall of the first cabinet 1 is also rotatably connected with a double threaded rod 205, and the double threaded rod 205 is connected to the rotating shaft 201 is provided with a transmission mechanism, and a moving mechanism is provided on the double threaded rod 205. A concave plate 303 is fixedly connected to the top of the moving mechanism, and a sliding block 304 is slidably connected to the concave plate 303. The wood body 4 is offset against the sliding block 304, and the first The top o...

Embodiment 2

[0042] refer to Figure 1-6 , a curved surface flexible intelligent grinding robot based on the Internet, including a first box body 1, a second box body 101, a protective cover 102, a polishing arm 103 and a wood body 4, the polishing arm 103 is located on the top of the first box body 1, and the second A tank 1 is provided with a water tank 8, the side wall of the water tank 8 is provided with a motor 2, the output end of the motor 2 is connected with a rotating shaft 201, and the inner wall of the first cabinet 1 is also rotatably connected with a double threaded rod 205, and the double threaded rod 205 is connected to the rotating shaft 201 is provided with a transmission mechanism, and a moving mechanism is provided on the double threaded rod 205. A concave plate 303 is fixedly connected to the top of the moving mechanism, and a sliding block 304 is slidably connected to the concave plate 303. The wood body 4 is offset against the sliding block 304, and the first The top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com