Polishing equipment for stainless steel products

A technology for stainless steel and products, applied in the field of polishing equipment for stainless steel products, can solve the problems of general removal effect, difficult scale, rust removal, etc., to achieve the effect of intensifying movement and improving the effect of pickling and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

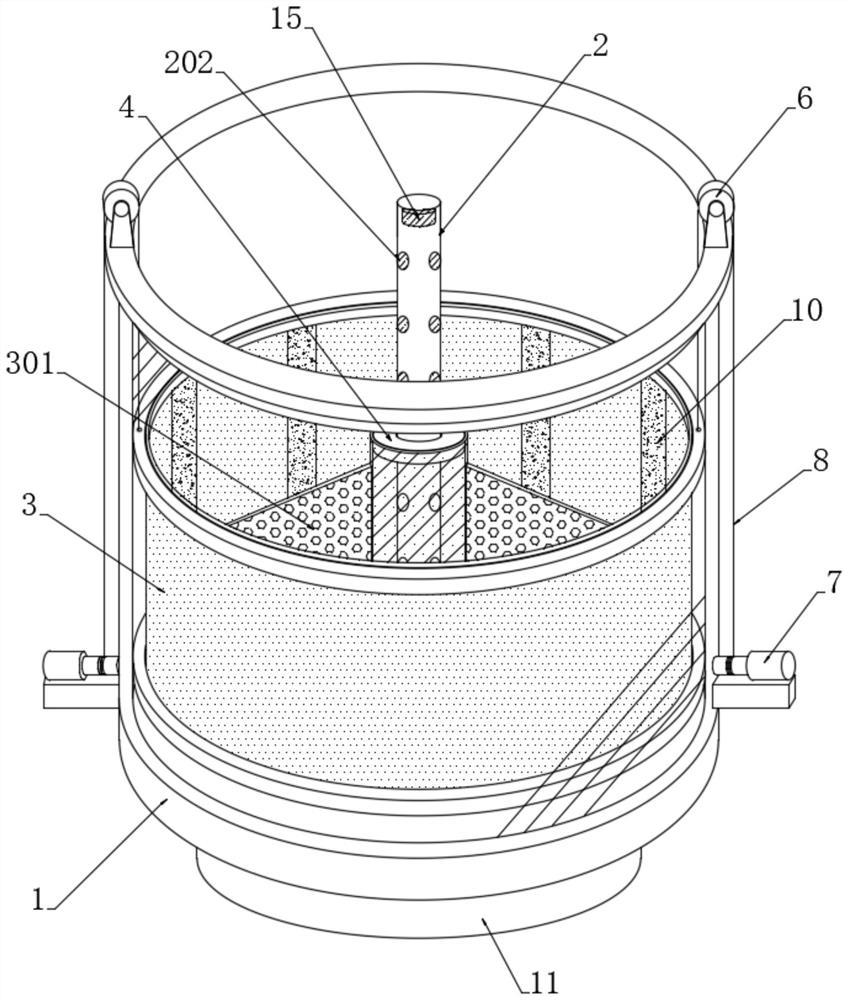

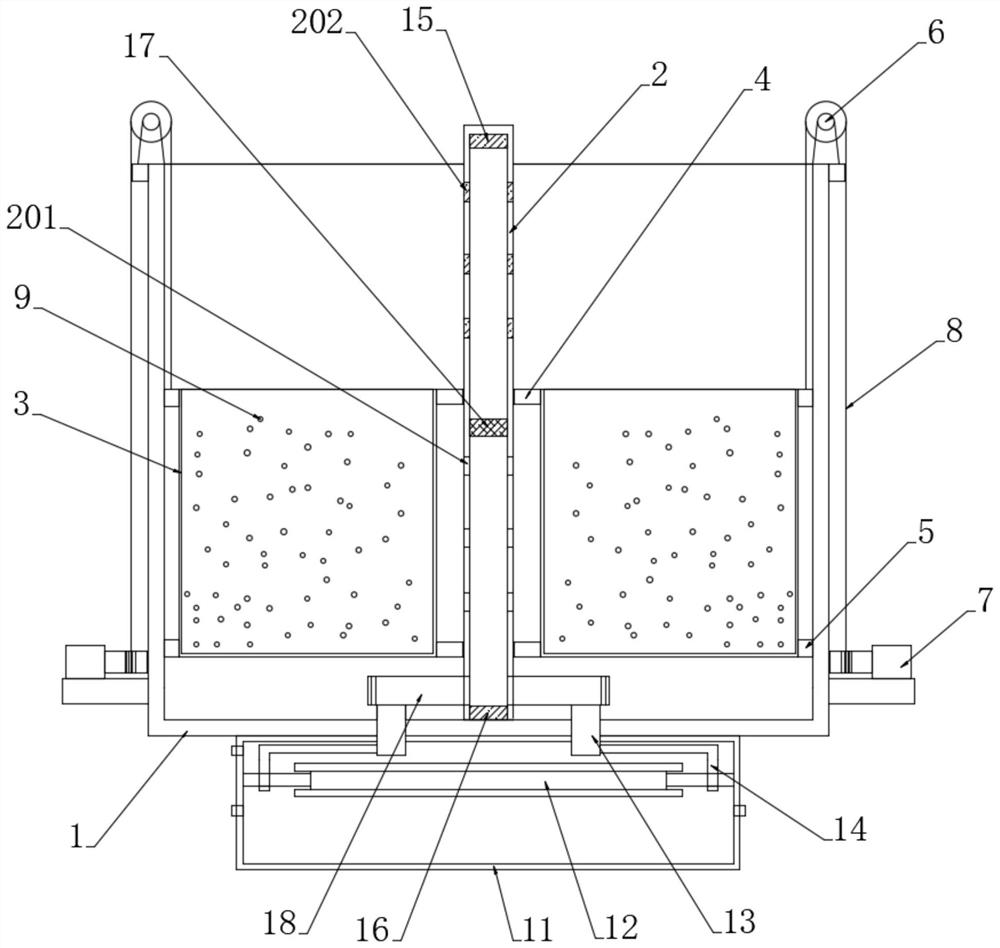

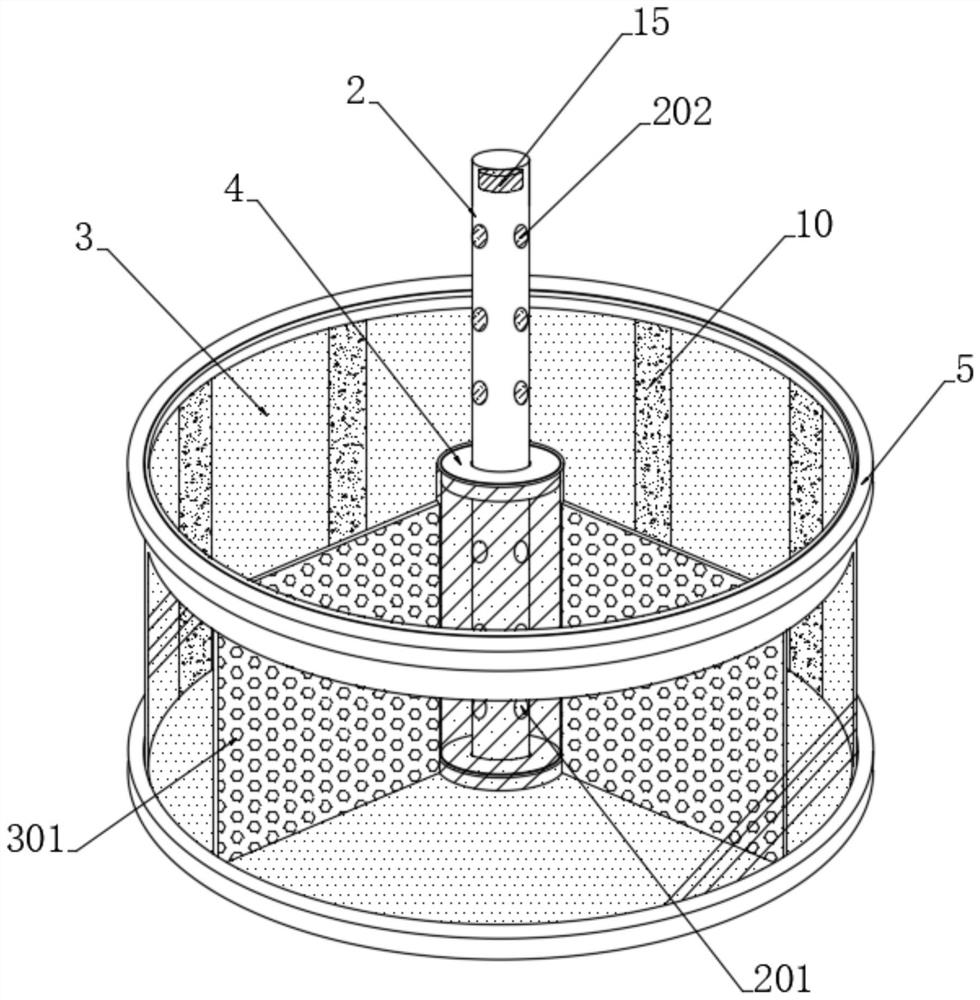

[0037] see Figure 1-5 , a kind of polishing equipment for stainless steel products, comprising a pickling box 1, the inner middle part of the pickling box 1 is fixedly connected with a jet vertical pipe 2, the sliding sleeve on the jet vertical pipe 2 is provided with a polishing box 3, and the interior of the polishing box 3 There is a ring-shaped polishing chamber, and the left and right sides of the pickling box 1 are equipped with a lifting mechanism connected to the top of the polishing box 3. A hollow cavity is provided in the middle of the polishing box 3, and the upper and lower ends of the hollow cavity are fixedly connected with sliding sleeves. The inner sliding ring 4 arranged on the spray standpipe 2, the inner wall of the annular polishing cavity and the hollow cavity are all provided with filter holes, and the filter holes are used for the through-flow of the pickling fluid, and the outer walls of the upper and lower ends of the polishing box 3 are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com