Silicon crystal groove type wet texturing circulating filtration treatment method

A technology of circulating filtration and treatment method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve problems such as inability to effectively reduce concentration and viscosity, inability to effectively remove liquid medicine, and weakened cleaning ability, so as to improve cleaning ability , save the amount, remove the effect of metal contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A kind of silicon crystal tank type wet texturing circulation filtration treatment method,:

[0036] Include the following steps:

[0037] D1. Initial alkaline cleaning: Insert the silicon wafer into the flower basket, enter the initial alkaline cleaning for removing silicon compounds and contamination on the surface, put the silicon wafer into the alkaline cleaning tank with alkaline cleaning solution, and the alkaline cleaning solution has a weight ratio of The composition of H2O and H2O2 is 20:1. The alkaline cleaning tank and the alkaline cleaning tank source used to provide the alkaline cleaning tank form a circulating liquid supply. The liquid inlet of the alkaline cleaning tank is provided with a filter element for filtering the alkaline cleaning tank. The initial alkali The cleaning time is usually ten minutes, and the cleaning liquid is kept circulating and filtered during the alkali cleaning process. The filter element is 5-50um, the diameter of ...

Embodiment 2

[0045] Embodiment 2: A kind of silicon crystal tank type wet texturing circulation filtration treatment method,:

[0046] Include the following steps:

[0047] D1. Initial alkaline cleaning: insert the silicon wafer into the flower basket, enter the initial alkaline cleaning for removing silicon compounds and stains on the surface, put the silicon wafer into the alkaline cleaning tank with alkaline cleaning solution, and the initial alkaline cleaning usually lasts for ten minutes .

[0048] D2. Alkali polishing, for surface polishing.

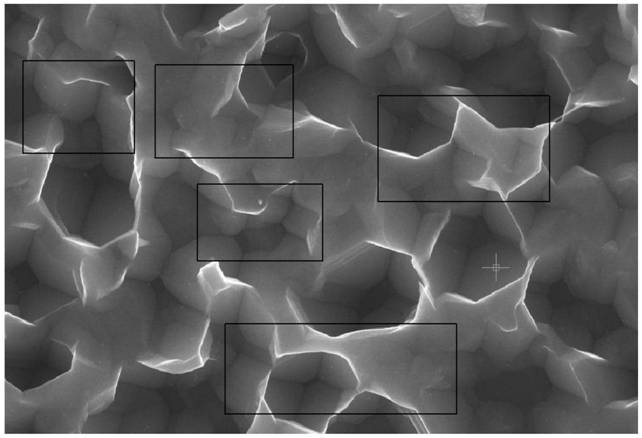

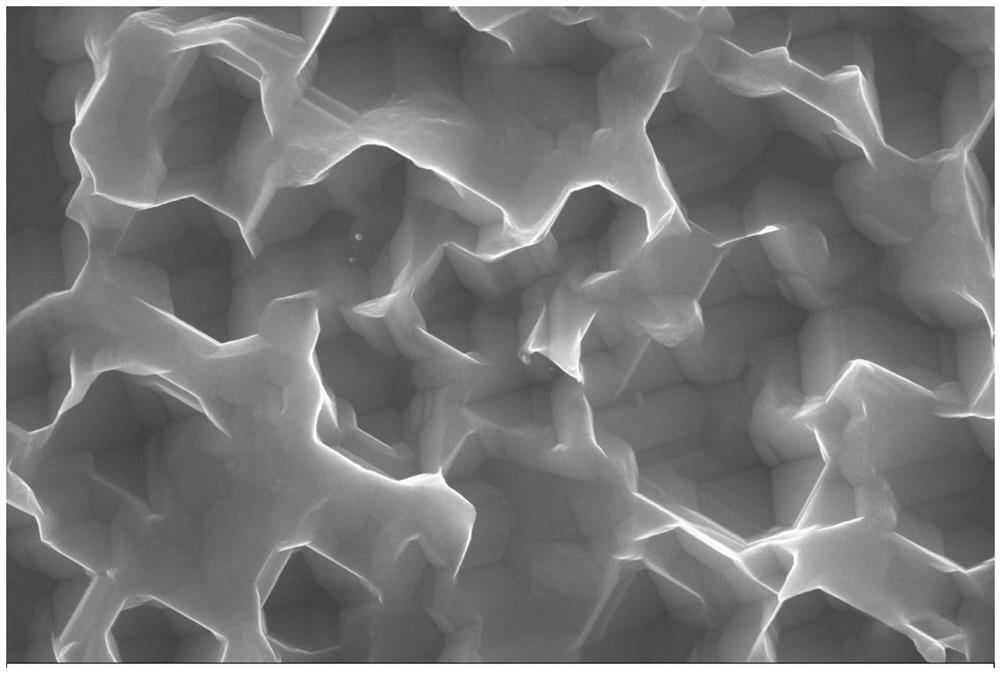

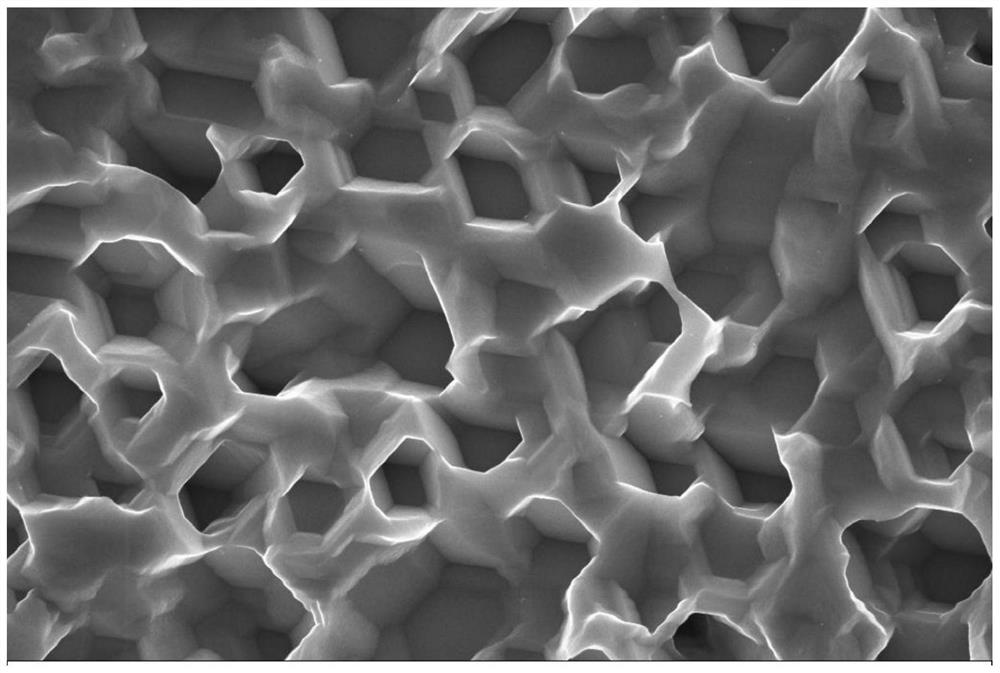

[0049] S1. Texture making, configure texturing liquid, put the silicon wafer into the texturing liquid and let it stand until the depth of the corrosion pit of the silicon wafer reaches 200-700nm, the width of the corrosion pit reaches 400-1200nm, and take out the silicon wafer;

[0050] S2. washing for the first time, the silicon wafer is placed in a cleaning tank with cleaning solution, and the washing time is usually 25 minutes;

[0051] ...

Embodiment 3

[0059] Embodiment 3: A kind of silicon crystal tank type wet texturing circulation filtration treatment method,:

[0060] Include the following steps:

[0061] D1. Initial alkaline cleaning: Insert the silicon wafer into the flower basket, enter the initial alkaline cleaning for removing silicon compounds and contamination on the surface, put the silicon wafer into the alkaline cleaning tank with alkaline cleaning solution, and the alkaline cleaning solution has a weight ratio of The composition of H2O and H2O2 is 20:1. The alkaline cleaning tank and the alkaline cleaning tank source used to provide the alkaline cleaning tank form a circulating liquid supply. The liquid inlet of the alkaline cleaning tank is provided with a filter element for filtering the alkaline cleaning tank. The initial alkali The washing time is usually ten minutes.

[0062] D2. Alkali polishing, configure the KOH (NOH) and H2O liquid medicine with a weight ratio of 3:10 for surface polishing, the polis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com