Multi-test-piece bonding joint tension and compression fatigue test device considering temperature influence

A technology of fatigue test and multiple specimens, which is applied in the field of bonded joint fatigue performance testing, can solve the problems of bonded joints under pressure, failure to realize fatigue life prediction, low efficiency, etc., and achieve the effect of reducing gap and load impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

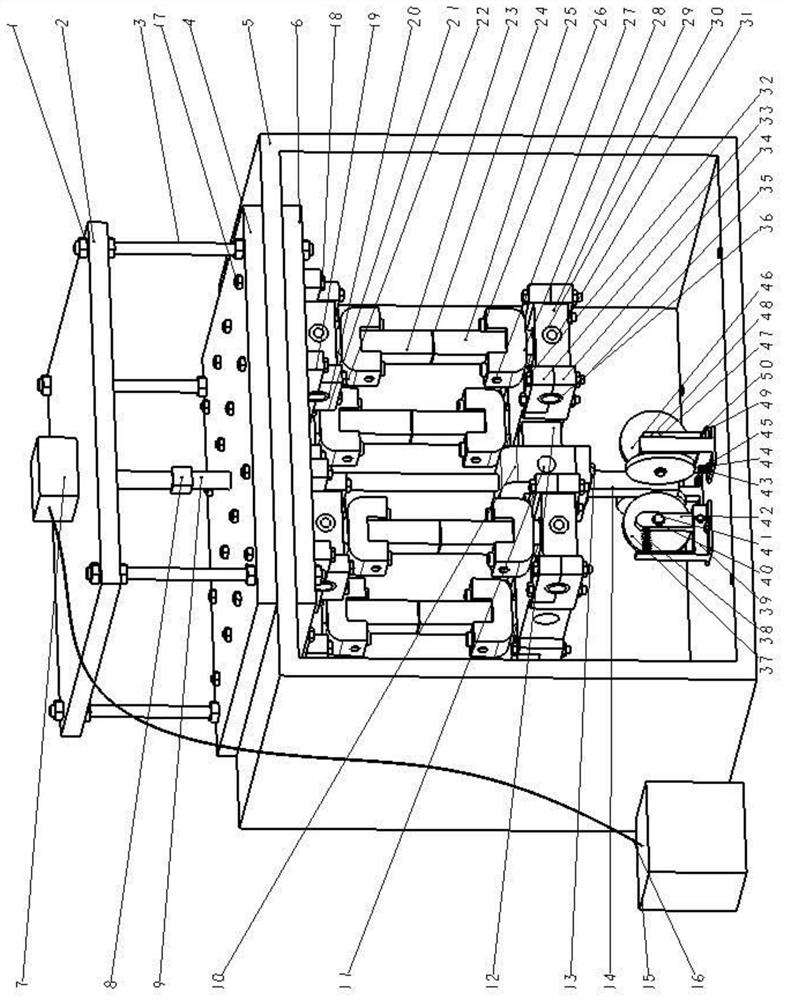

[0131] Such as figure 1 As shown, the main structure of a multi-specimen bonded joint tension-compression fatigue test device considering the temperature influence of the present invention is composed of an environmental box device, a power input device, an upper pressing device, a bonded joint, and a test piece support cross shaft. It consists of a device, a lower pressing device, a movable limiter device, and a fixed limiter device.

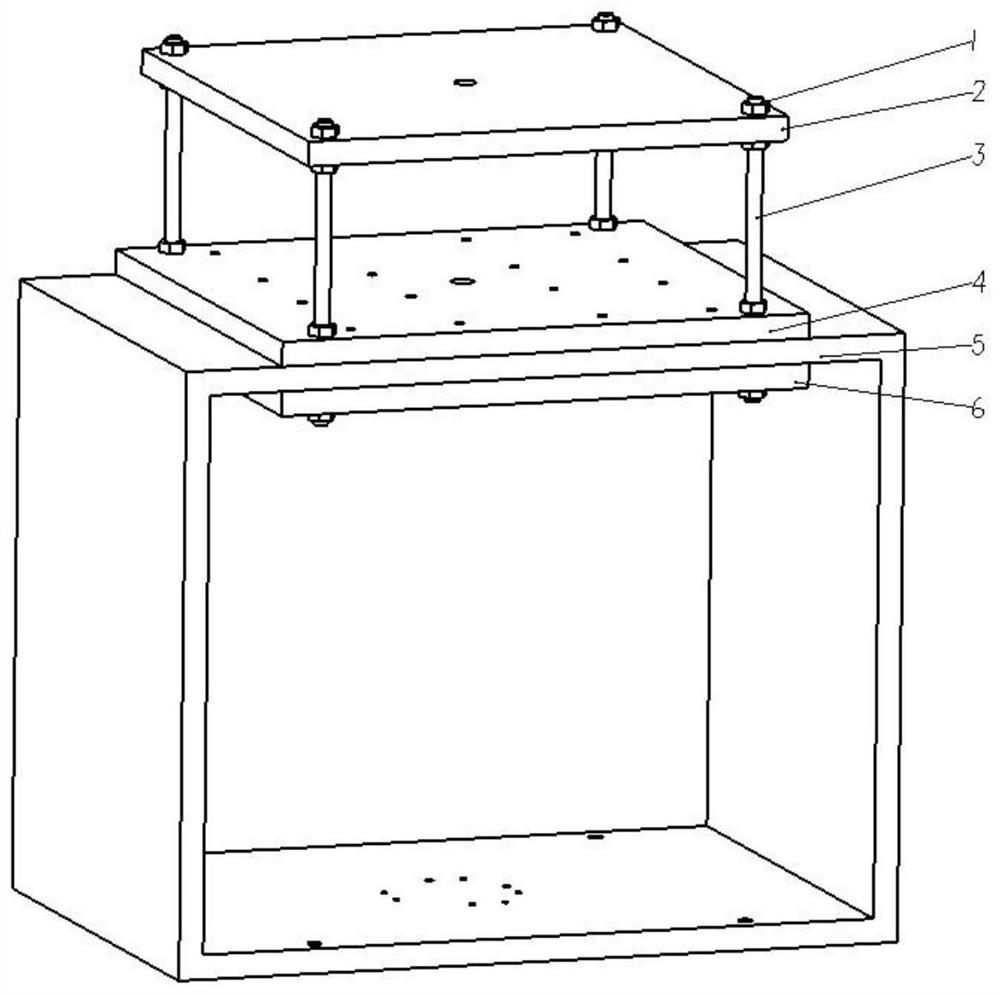

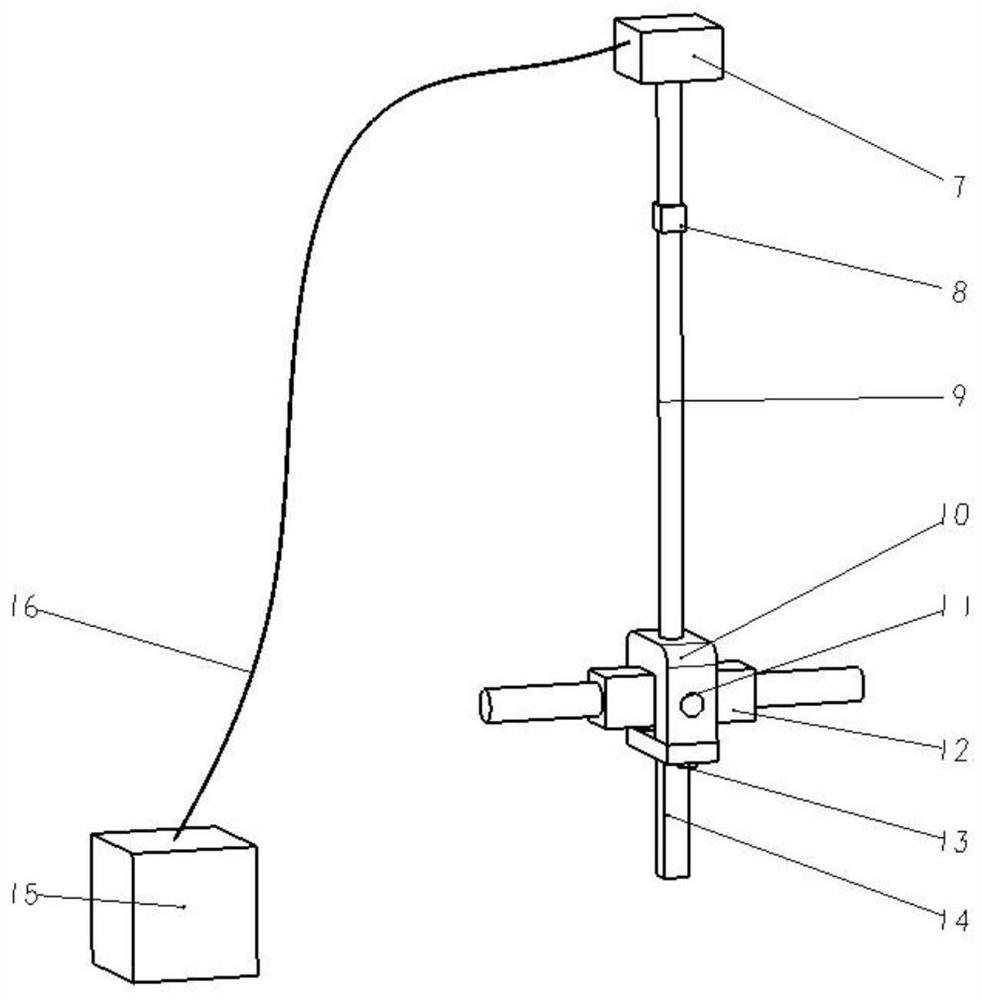

[0132] Among them, the environment box device mainly includes: oil cylinder support plate 2, threaded rod 3, environment box upper support plate 4, environment box 5, environment box lower support plate 6; power input device mainly includes: oil cylinder 7, sensor 8, telescopic rod 9 , U-shaped part 10, balance beam pin shaft 11, first-level balance beam 12, T-shaped limit piece 14, control box 15, control line 16; the upper pressing device mainly includes: upper pressing fixed block 19, upper pressing Block 21; the test piece support cross sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com