A heat shield structure for single crystal production furnace and single crystal production furnace

A single crystal and growth furnace technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as uneven temperature gradients, achieve the effects of improving quality uniformity, achieving pulling speed, and high heat reflection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

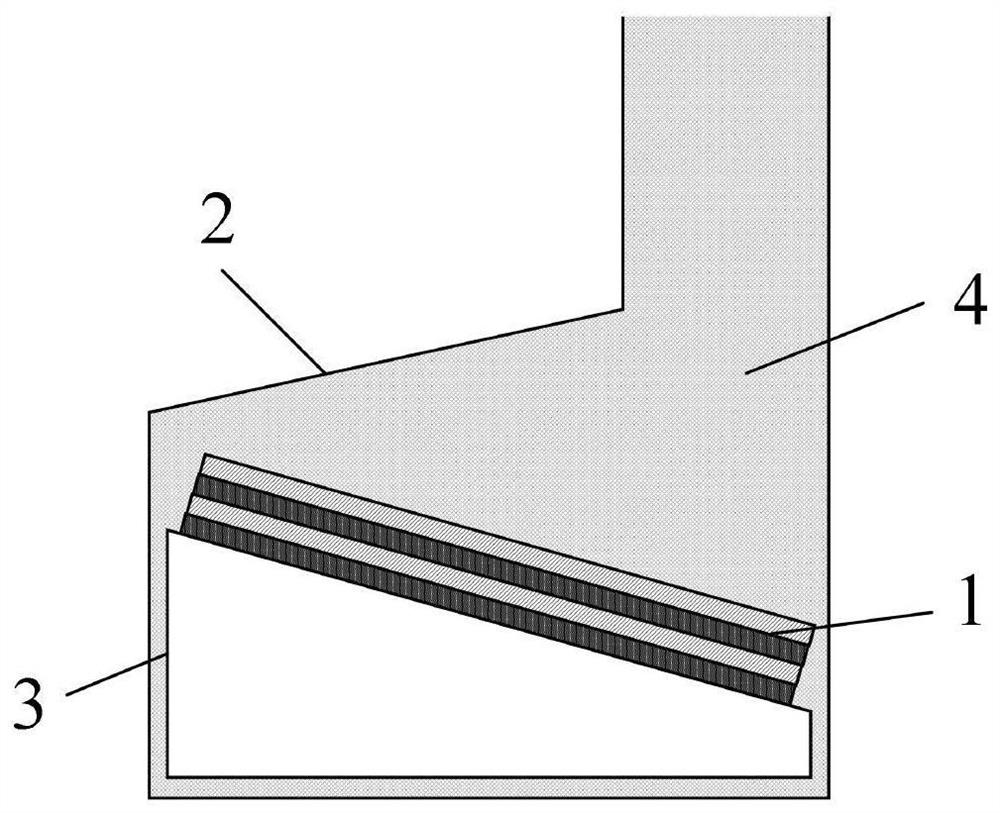

[0037] refer to figure 1 and Figure 4 , a heat shield structure for a single crystal production furnace, wherein the heat shield structure 8 is used to be arranged on the upper part of the melt crucible 6 of the single crystal growth furnace, the heat shield structure 8 includes a shell 2 and a heat shield 1, and the heat shield 1 is located inside the shell 2, the outer surface of the bottom of the shell 2 is used to face the inside of the melt crucible 6, and the angle formed by the plane where the heat shield 1 is located and the plane where the bottom of the shell 2 is located is an acute angle, and the included angle faces the outside of the monocrystalline silicon 7 surface. By changing the design of the heat shield and adding a heat shield to transfer the heat dissipated from the melt to the single crystal silicon, that is, a heat channel is formed in the heat shield structure to optimize the radial temperature gradient of the single crystal silicon, thereby realizing...

Embodiment 2

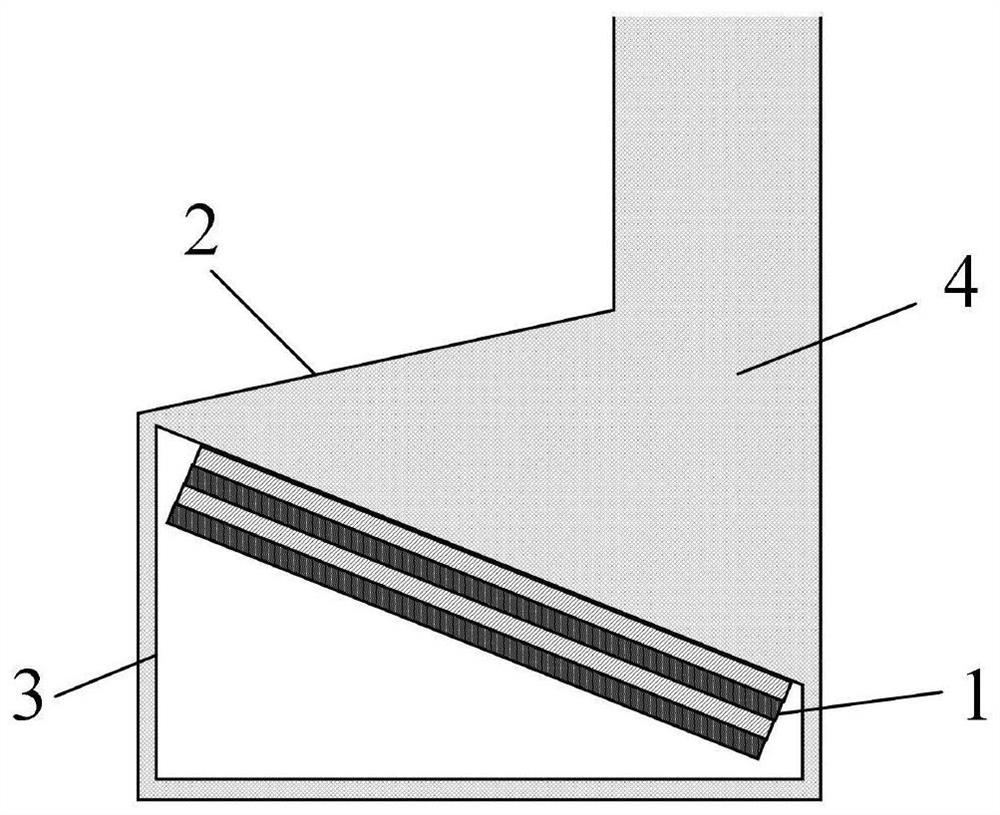

[0043] The difference between this embodiment and Embodiment 1 lies in that the position where the heat insulation board 1 is placed is different. Such as figure 2 As shown, in this embodiment, the heat insulation board 1 is arranged inside the inner shell 3 . The heat shield structure 8 includes an outer shell 2 and a heat shield 1. The heat shield 1 is arranged inside the outer shell 2 and inside the inner shell 3. The outer surface of the bottom of the outer shell 2 is used to face the inside of the melt crucible 6. The heat shield 1 The included angle formed by the plane where it is located and the plane where the bottom of the housing 2 is located is an acute angle, and the included angle faces the outer surface of the single crystal silicon 7 . The included angle between the plane where the heat insulating board 1 is located and the horizontal plane is 30 degrees. In other embodiments, the included angle between the plane where the heat insulating board 1 is located an...

Embodiment 3

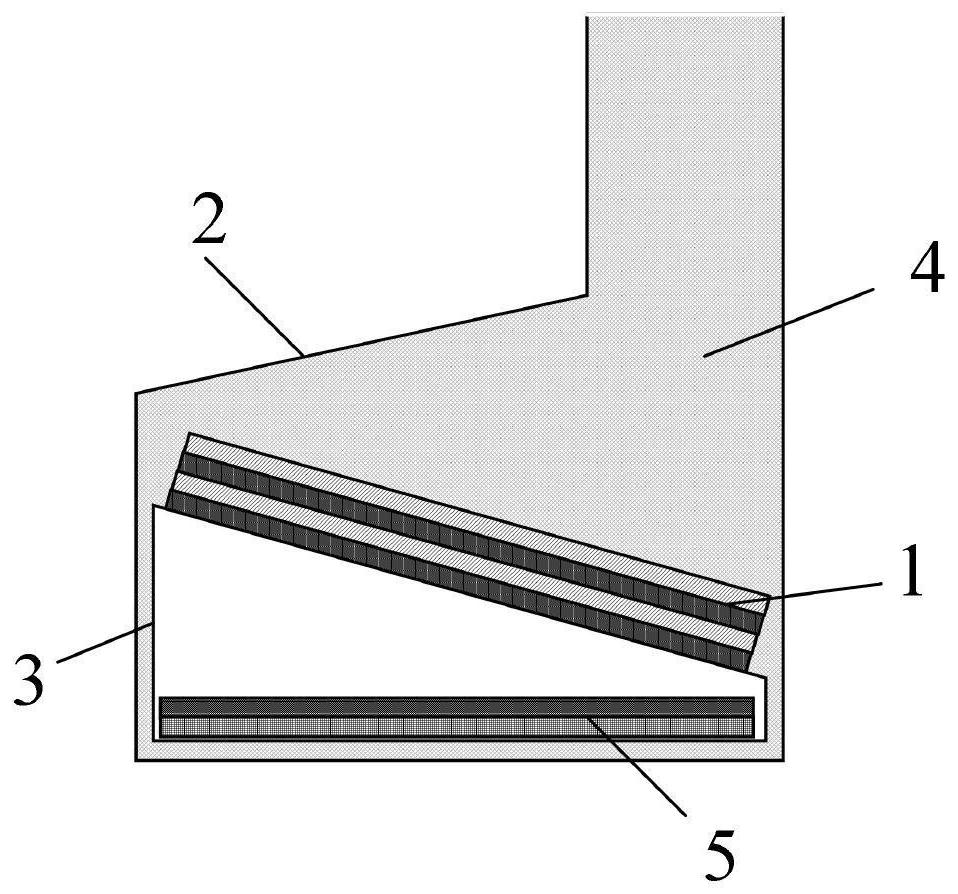

[0047] The difference between this embodiment and the previous embodiments is that a heat absorbing plate is added in the heat shield structure. Such as image 3 As shown, a heat shield structure for a single crystal production furnace, wherein the heat shield structure 8 is used to be arranged on the upper part of the melt crucible 6 of the single crystal growth furnace, the heat shield structure 8 includes a shell 2 and a heat shield 1, and the heat shield structure 8 includes a shell 2 and a heat shield 1. The hot plate 1 is arranged inside the shell 2, the outer surface of the bottom of the shell 2 is used to face the inside of the melt crucible 6, and the angle formed by the plane where the heat shield 1 is located and the plane where the bottom of the shell 2 is located is an acute angle and the angle faces the monocrystalline silicon 7 of the outer surface.

[0048] It also includes a heat absorbing plate 5 and an inner shell 3, the inner shell 3 is arranged inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com