Antibacterial printing paste composition, method for preparing glazed tiles using same, and glazed tiles

A composition and technology for glazed tiles, applied in the field of building ceramics, can solve the problems of poor bacteriostatic effect and durability, long bacteriostatic effect, high temperature burning loss of bacteriostatic agents, etc., and achieve good bacteriostatic performance, long bacteriostatic effect, Reduce the effect of high temperature ignition loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

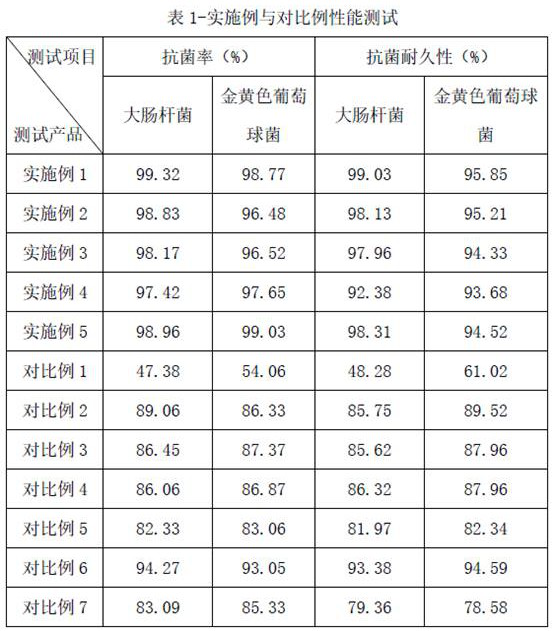

Examples

preparation example Construction

[0042] A kind of preparation method of glazed tile, uses described antibacterial printing paste composition, comprises the following steps:

[0043] A, preparation of antibacterial printing paste composition: after the antibacterial material bonding dispersant is ground, sieved and stale, add antibacterial agent and antibacterial material protective agent and stir evenly to obtain the antibacterial printing paste composition for subsequent use;

[0044] B. Blank making: Press the ceramic powder into a green body, and the green body is usually heated to 200-300°C and dried for 10-20 minutes, then gradually heated to 950-1050°C and kept for 5-15 minutes, and the green body is obtained after cooling ;

[0045] C. Surface treatment of the green body: After the green body is subjected to rough polishing and fine polishing, the surface temperature of the green body is controlled at 90-120°C, and then a surfactant is sprayed on the surface of the green body;

[0046]D, glazing: coat...

Embodiment 1

[0107] A preparation method for glazed tiles, comprising the steps of:

[0108] A, preparation of antibacterial printing paste composition: adopt the preparation method of antibacterial printing paste composition a as above, obtain antibacterial printing paste composition for subsequent use;

[0109] B. Blank making: Press the ceramic powder into a green body. The green body is usually heated to 250°C and dried for 15 minutes, and then gradually heated to 1000°C for 10 minutes. The moisture content of the green body is 5.5%. After cooling get biscuit;

[0110] C. Surface treatment of the green body: use a 30-mesh abrasive belt to roughly polish the green body once, use a 60-mesh abrasive belt to perform fine polishing on the green body twice, control the surface temperature of the green body to 100°C, and then Surfactant (using conventional non-ionic surfactant) is sprayed on the surface, and the spraying amount of the surfactant is 75g / m 2 ;

[0111] D, glazing: adopt the ...

Embodiment 2

[0114] A preparation method for glazed tiles, comprising the steps of:

[0115] A, preparation of the antibacterial printing paste composition: adopt the preparation method of the antibacterial printing paste composition b as described above to obtain the antibacterial printing paste composition for subsequent use;

[0116] B. Blank making: Press the ceramic powder into a green body. The green body is usually heated to 200°C and dried for 20 minutes, and then gradually heated to 950°C for 15 minutes. The moisture content of the green body is 5.5%. After cooling get biscuit;

[0117] C. Surface treatment of the green body: use a 30-mesh abrasive belt to roughly polish the green body once, use a 60-mesh abrasive belt to perform fine polishing on the green body twice, control the surface temperature of the green body to 90°C, and then Surfactants are sprayed on the surface (using conventional ionic surfactants), and the spraying amount of the surfactants is 85g / m 2 ;

[0118] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com