Preparation method and application of a kind of square phase bismuth oxide activated carbon photocatalyst

A technology of photocatalyst and activated carbon, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., which can solve the problems of failure to absorb visible light and achieve low cost and easy operation Simple, to avoid the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

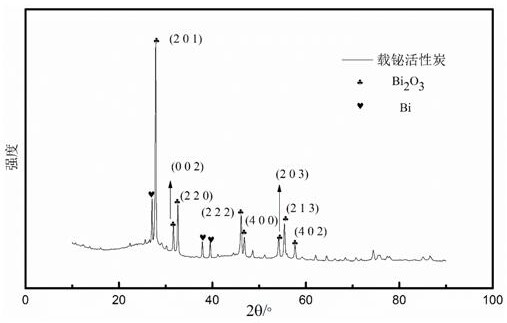

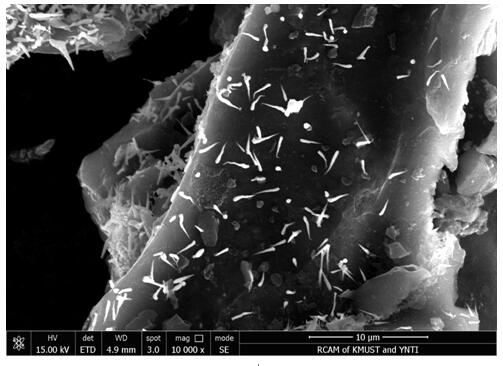

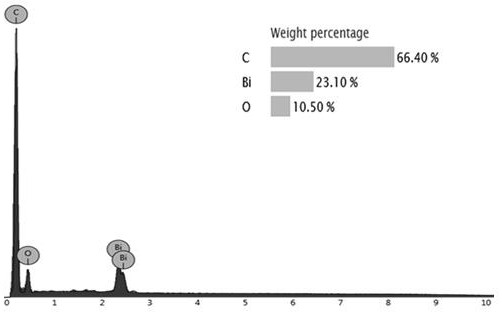

[0026] Embodiment 1: a kind of preparation method of square phase bismuth oxide activated carbon photocatalyst, concrete steps are as follows:

[0027] (1) Put the deactivated activated carbon under the conditions of microwave power of 800W and temperature of 600°C for 30 minutes to obtain regenerated activated carbon; the deactivated activated carbon is the deactivated activated carbon treated with anthraquinone, and the particle size of the deactivated activated carbon is The diameter is 180 mesh, and the methylene blue adsorption value is 30mg / g;

[0028] (2) Mix the regenerated activated carbon in step (1) with lysine solution and bismuth nitrate solution evenly, impregnate and react for 180 minutes under stirring conditions, and then place it in microwave roasting for 10 minutes at a microwave power of 700W and a temperature of 500°C. Pros and Cons 2 o 3 -AC photocatalyst; Wherein the concentration of lysine solution is 0.5 g / L, the concentration of bismuth nitrate solu...

Embodiment 2

[0030] Embodiment 2: a kind of preparation method of square phase bismuth oxide activated carbon photocatalyst, concrete steps are as follows:

[0031] (1) Put the deactivated activated carbon under the conditions of microwave power of 1000 W and temperature of 900 °C for 10 minutes to obtain regenerated activated carbon; the deactivated activated carbon is the deactivated activated carbon treated with anthraquinone, and the deactivated activated carbon is The particle size is 200 mesh, and the adsorption value of methylene blue is 45mg / g;

[0032] (2) Mix the regenerated activated carbon in step (1) with lysine solution and bismuth nitrate solution evenly, impregnate and react for 120 minutes under stirring conditions, and then place it in microwave roasting for 30 minutes at a microwave power of 500W and a temperature of 300°C. Pros and Cons 2 o 3 -AC photocatalyst; Wherein the concentration of lysine solution is 0.1 g / L, the concentration of bismuth nitrate solution is 0....

Embodiment 3

[0034] Embodiment 3: a kind of preparation method of square phase bismuth oxide activated carbon photocatalyst, concrete steps are as follows:

[0035](1) Put the deactivated activated carbon under the conditions of microwave power of 1000W and temperature of 800°C for 20 minutes to obtain regenerated activated carbon; the deactivated activated carbon is deactivated activated carbon treated with anthraquinone, and the particle size of the deactivated activated carbon is 200 mesh, methylene blue adsorption value is 45mg / g;

[0036] (2) Mix the regenerated activated carbon in step (1) with lysine solution and bismuth nitrate solution evenly, impregnate and react for 160 minutes under stirring conditions, and then place it in microwave roasting for 20 minutes at a microwave power of 1000W and a temperature of 900°C. Pros and Cons 2 o 3 -AC photocatalyst; Wherein the concentration of lysine solution is 0.1 g / L, the concentration of bismuth nitrate solution is 0.15mol / L, the soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com