Heating furnace device with combustor

A burner and heating furnace technology, applied in the field of heating furnaces, can solve the problems of low power, waste of fuel, low efficiency, etc., and achieve the effects of improving the activity of lime products, improving the rate of lime products, and reducing fuel costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

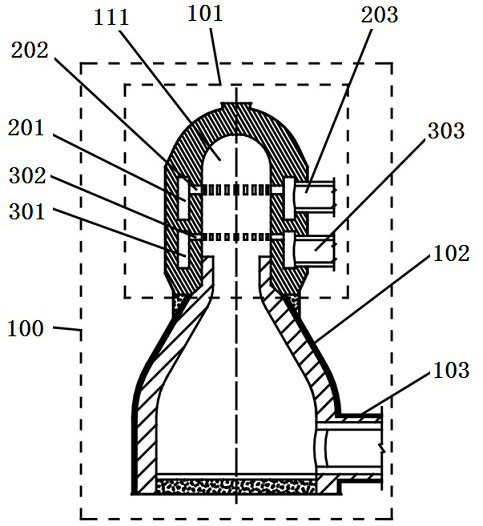

[0029] The present invention provides a heating furnace device 100 with a burner, such as figure 1 As shown, it includes a burner 101 and a dome 102, the burner 101 has a pre-chamber 111 with an opening facing downwards, the burner 101 is arranged above the dome 102 and the pre-chamber 111 communicates with the inner cavity of the dome 102 The inner cavity of the vault 102 includes a cylindrical portion at the bottom, a conical portion at the top, and an arc transition portion at the middle, and the pre-combustion chamber 111 includes a cylindrical section at the bottom and an upper section at the top of the cylindrical section In a spherical vault, the central axis of the burner coincides with the central axis of the vault, and the diameter of the cylindrical portion of the vault’s inner chamber is larger than that of the cylindrical section of the pre-combustion chamber.

[0030] The lining of the burner and the vault adopts a labyrinth connection (the labyrinth is also call...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com