A zoned tissue combustion self-denitration system and process with a reduction furnace and a decomposition furnace

A technology of partition organization and decomposition furnace, which is applied in the direction of furnace components, furnaces, separation methods, etc., can solve the problems of short residence time of denitrification reaction, limited space of oxygen-poor combustion area, and inability to reduce NOx, etc., so as to reduce the cost of environmental protection treatment of enterprises , strong operability and practicability, and the effect of improving the efficiency of self-denitration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

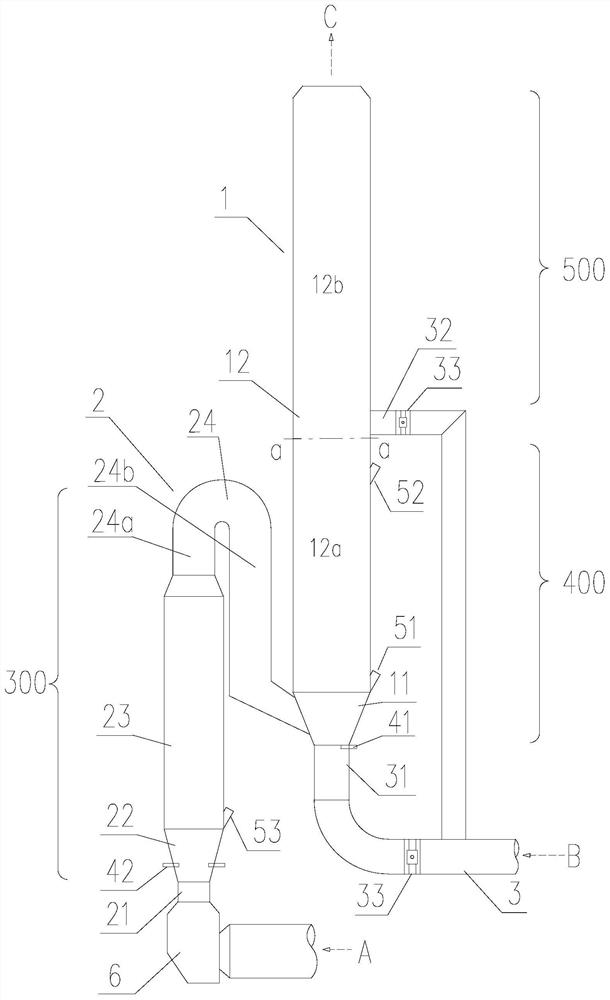

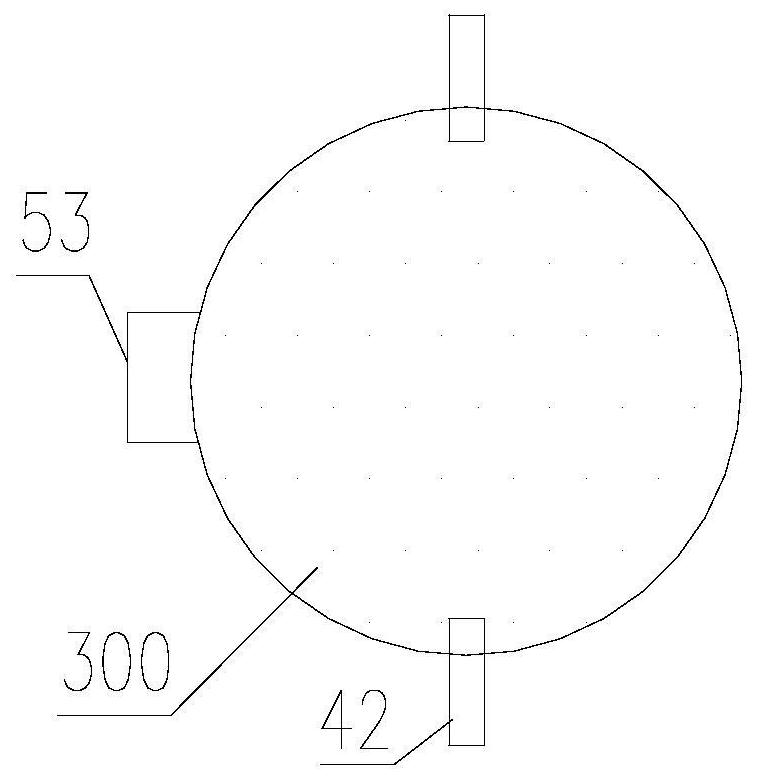

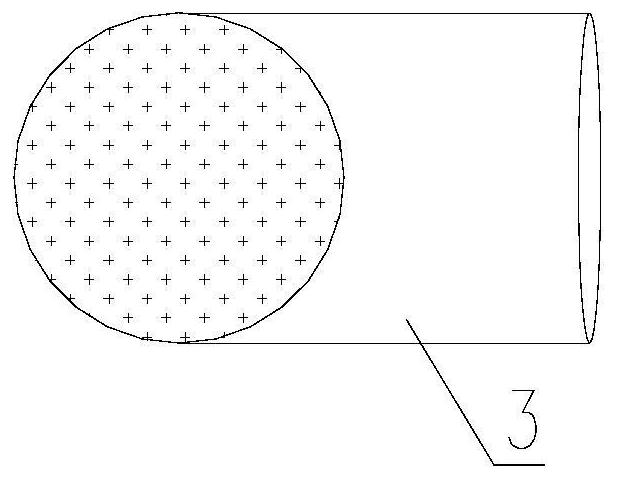

[0077] see Figure 1~4 , the embodiment of the present invention provides a zone organization combustion self-denitration system with a reduction furnace and a decomposition furnace, including a rotary kiln, a kiln tail smoke chamber 6 connected to the kiln tail of the rotary kiln, a decomposition furnace 1, a kiln tail smoke chamber 6 and The reduction furnace 2 of the decomposition furnace 1 and the tertiary air duct 3; The calciner 1, the reduction furnace 2 and the tertiary air duct 3 are all equipped with refractory materials.

[0078] The calciner 1 is located after the reduction furnace 2 , and the flue gas from the reduction furnace 2 and the tertiary air B are combined in the calciner 1 . The calciner 1 is composed of a calciner cone 11 and a calciner column 12 . The outlet of the reduction furnace 2 is connected to the side of the calciner cone 11 or the bottom side of the calciner cylinder 12. In this embodiment, the outlet of the reduction furnace 2 is connected ...

Embodiment 2

[0091] The difference from Embodiment 1 is that the calciner cylinder 12 is provided with a narrowing 13 in the middle of the calciner.

[0092] see Figure 5 , The calciner cylinder 12 is provided with a calciner middle shrinkage 13 . The shrinkage 13 in the middle of the calciner is located below the upper feeding point 52 of the raw meal of the calciner. The raw meal that enters from the raw meal upper feeding point 52 of the calciner tends to move downward under the action of gravity. By setting the calciner middle neck 13 below the raw meal upper feed point 52 of the calciner, the cross section at the neck The wind speed becomes larger than that of the cross-section of the cylinder, which can effectively reduce the falling height of raw materials and prevent material collapse in the calciner.

Embodiment 3

[0094] The difference from Embodiment 1 is that a discharge bin 71 , a material pipe 72 and an air lock valve 73 are arranged below the bottom elbow 311 of the tertiary air lower branch pipe.

[0095] see Image 6 . Preferably, a discharge bin 71 and a material pipe 72 connected to the discharge bin 71 are arranged below the bottom elbow of the lower branch pipe 31 of the tertiary air duct, and both ends of the material pipe 72 are connected to the discharge bin 71 and the kiln tail smoke chamber 6 . When there is an accident shutdown, the materials in the decomposition furnace can fall into the discharge bin 71 under the action of gravity, and enter the kiln tail smoke chamber 6 through the material pipe 72, and enter the rotary kiln, without manual cleaning of materials. The material pipe 72 is provided with an air lock valve 73, which is used to prevent or reduce the exiting kiln flue gas in the kiln tail smoke chamber 6 from blowing into the calciner from the material pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com