A method of embedding waste plastic green oily technology into garbage incineration

A technology of waste incineration and plastic waste, which can be used in combustion methods, waste fuels, fuels, etc., and can solve the problems of low social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

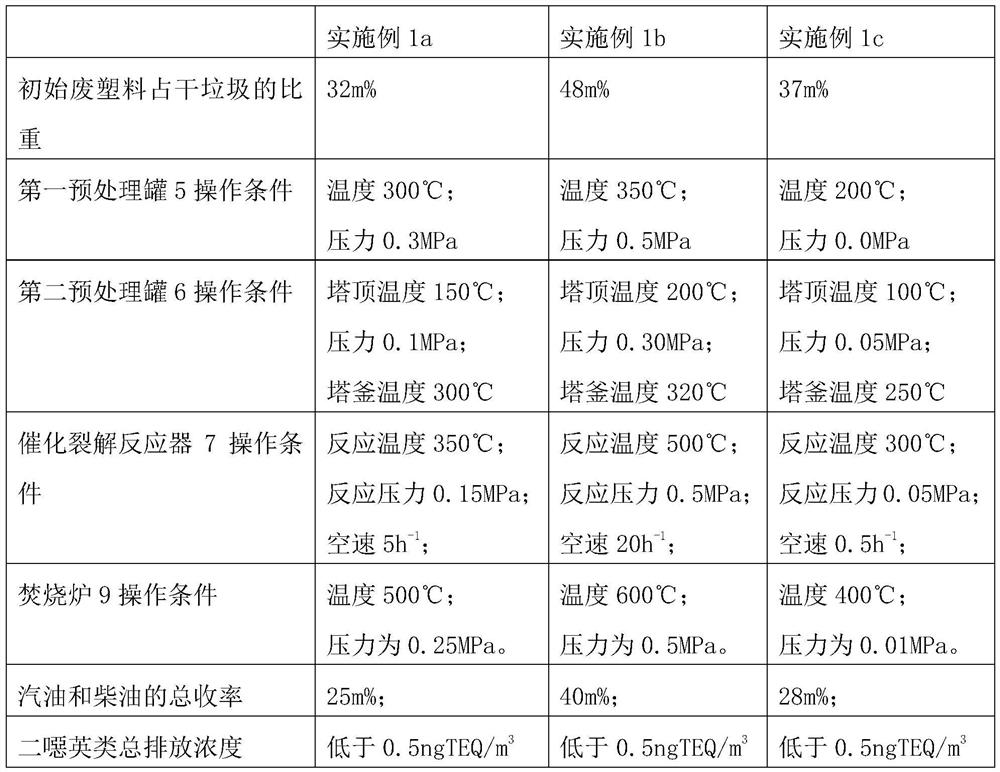

Embodiment 1

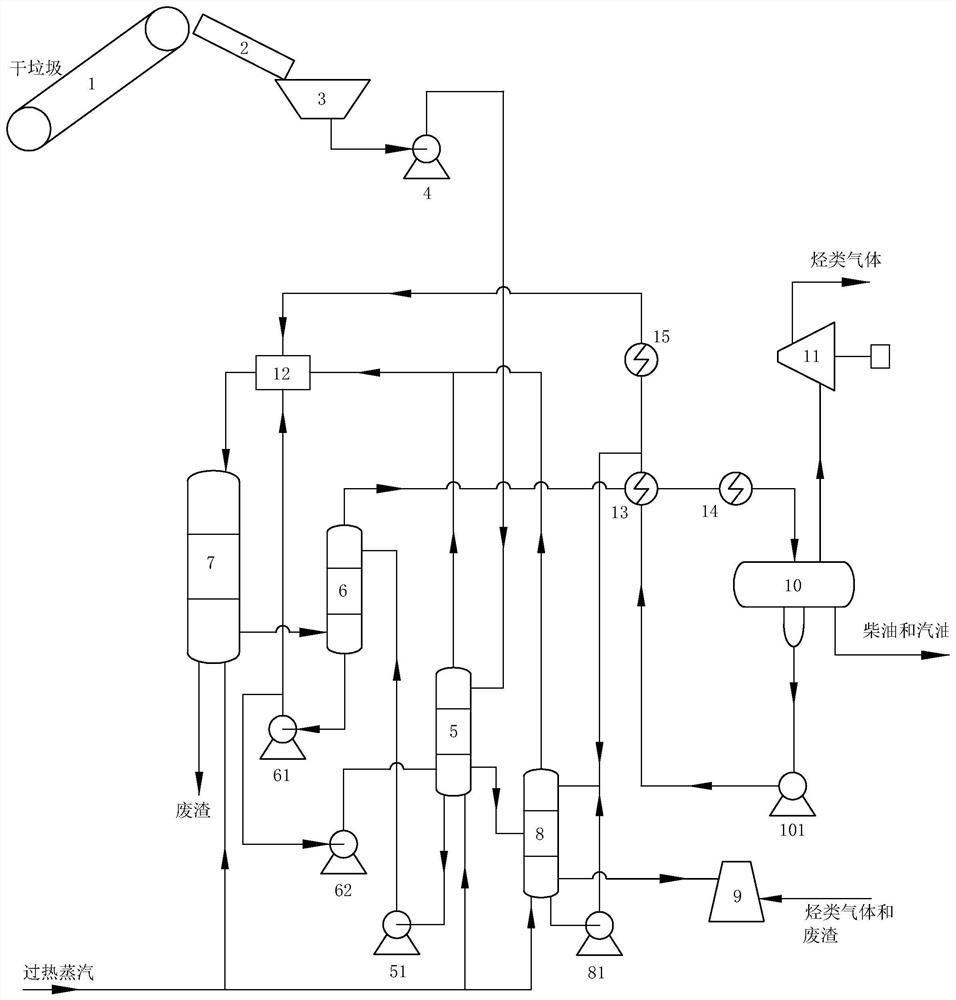

[0046] Such as figure 1 As shown, the waste plastic green oilization technology of this embodiment is embedded in the garbage incineration method, including the following steps:

[0047] S1 dry garbage pretreatment unit operation: the dry garbage obtained after dry-wet separation (waste moisture content less than 15%) is conveyed through the conveyor belt 1, and large pieces of batteries, glass and stones are manually picked in the process The solid waste is removed, and then the iron lumps in the dry garbage are removed through the pipeline iron remover 2, and after being shredded by the shredder 3, it is transported into the middle section of the first pretreatment tank 5 by the screw propeller 4. Dry garbage includes waste plastics and non-plastic garbage. The waste plastics account for 42m% of the dry garbage. The waste plastics are mainly soft plastics such as plastic films and plastic packaging bags. The non-plastic garbage mainly refers to kitchen rubbish such as surpl...

Embodiment 2

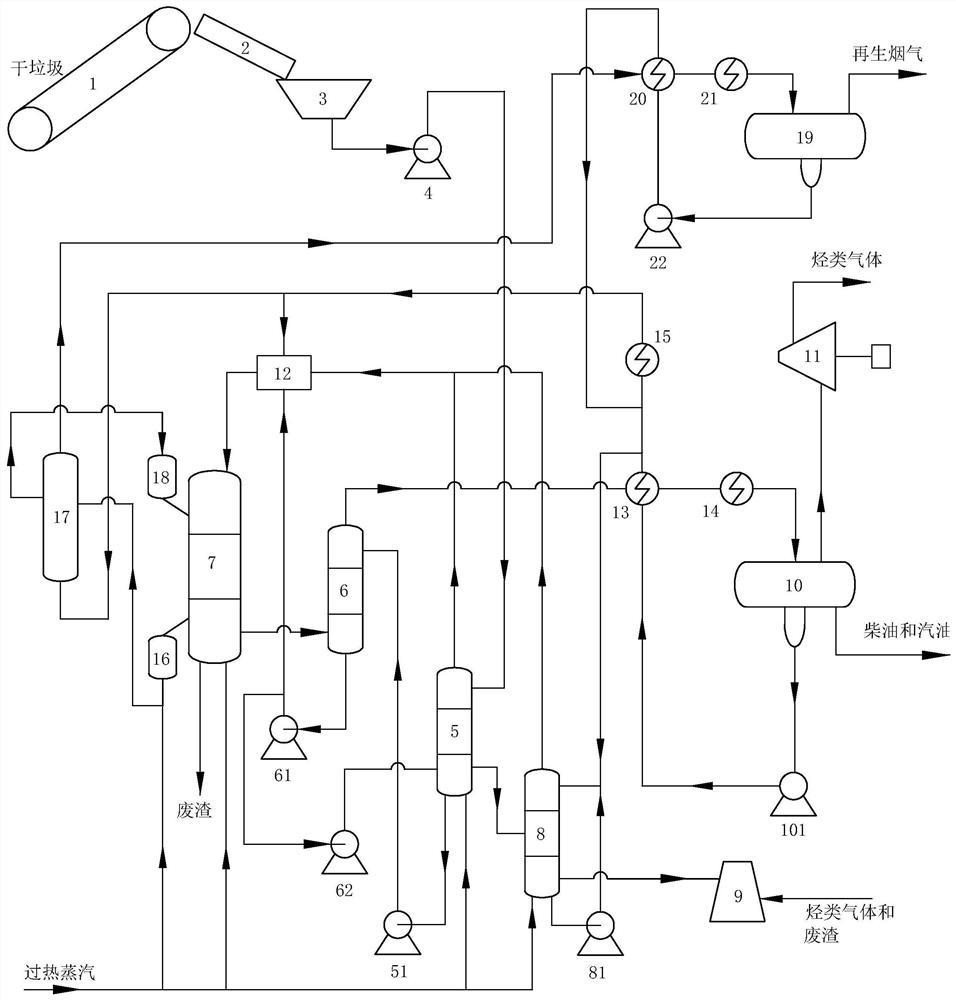

[0062] Such as figure 2 As shown, the waste plastic green oilization technology embedded in the waste incineration method in this embodiment also includes the following processing steps: S1 dry waste pretreatment unit operation; S2 liquefied waste plastic cracking unit operation; and S3 non-plastic waste incineration unit operation.

[0063] Difference with embodiment 1 is that, in described step S2, also comprise the regeneration process of catalyst, it mainly comprises the following steps; Catalyst leaves catalytic cracking reactor 7 by unloading line, is collected in surge tank 16, described Steam is passed into the buffer tank 16 to remove the oil and gas carried on the catalyst; then the catalyst is transferred to the regenerator 17, and a superheated medium and an appropriate amount of air are passed into the regenerator 17 to convert the carbon deposits on the catalyst into CO 2 and H 2 0, catalyst activity can recover gradually; The catalyst after the regeneration is...

Embodiment 3

[0065] The waste plastic green oilization technology embedded in the waste incineration method of this embodiment also includes the following processing steps: S1 dry waste pretreatment unit operation; S2 liquefied waste plastic cracking unit operation; and S3 non-plastic waste incineration unit operation.

[0066] The difference from Example 1 is that in the step S3, the incinerator 9 adopts an indirect combustion method, and its operating conditions are as follows: the operating temperature is 550° C., the pressure is 0.2 MPa, and the non-plastic in the incinerator 9 Garbage is carbonized under anaerobic high-temperature conditions and converted into coke, and the coke is converted into carbon dioxide and water after combustion; the carbonization process is carried out in a mechanical grate furnace. The carbonization medium adopts superheated steam; the temperature of the superheated steam is 600°C and the pressure is 0.2MPa; in the mechanical grate furnace, the non-plastic u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com