Integrated modular group control air compressor optimization system

A technology of integrated modules and air compressors, applied in pump control, mechanical equipment, machines/engines, etc., can solve problems such as unsuitable for large-scale enterprise technological transformation, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

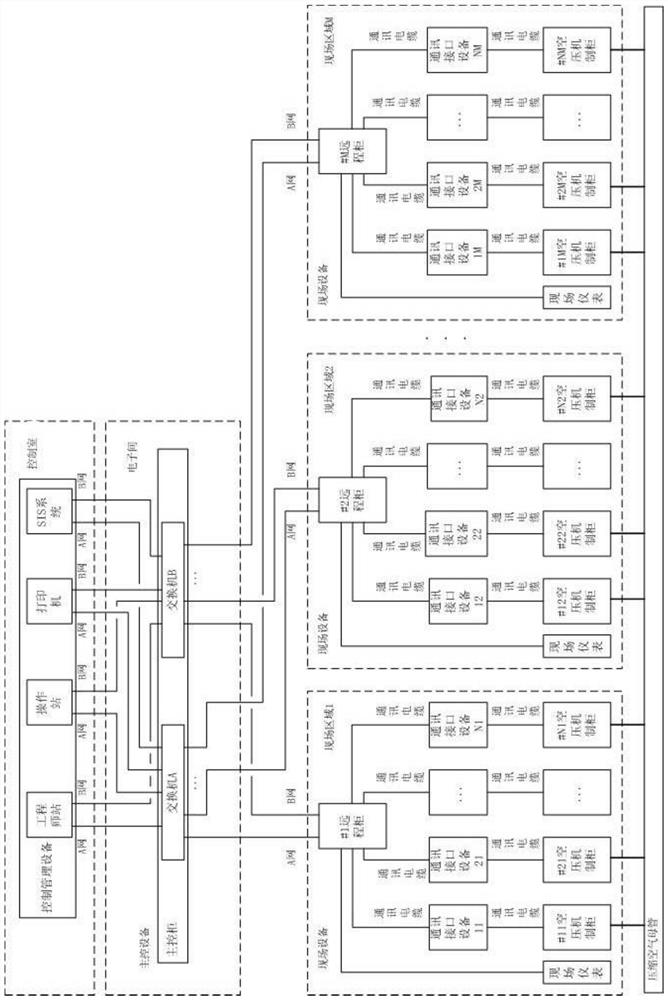

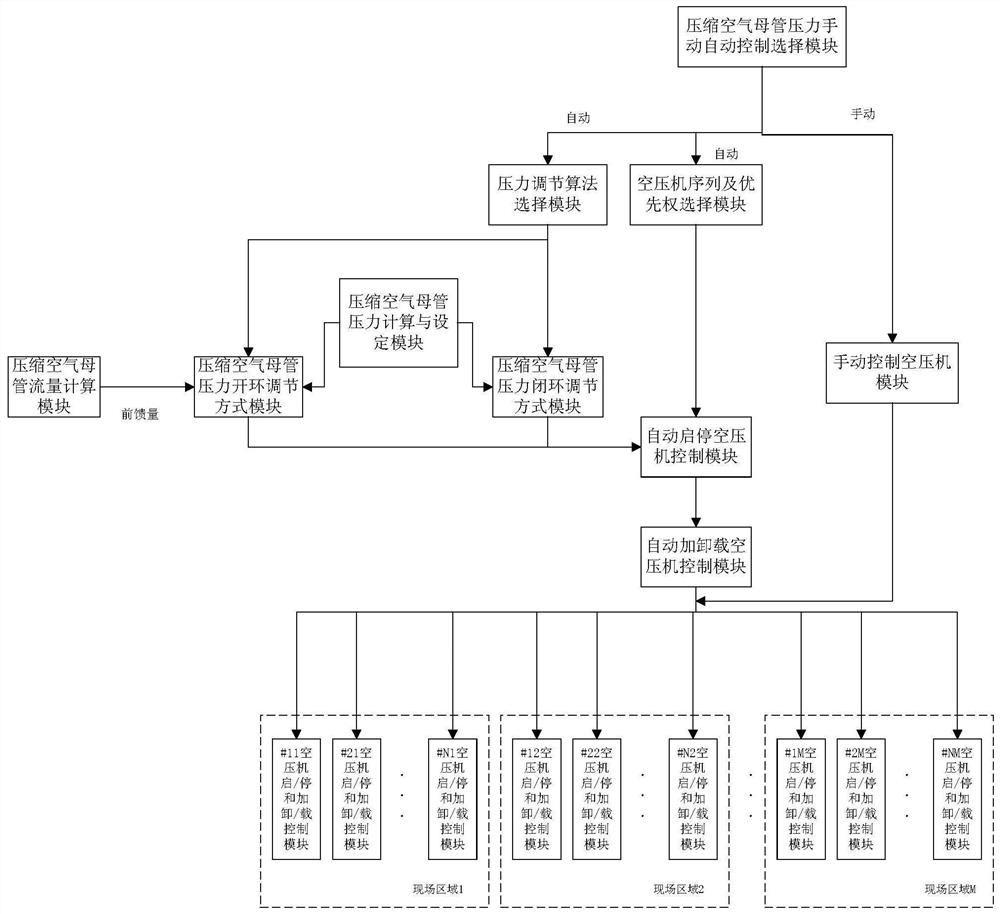

[0069] The invention will be further described below in conjunction with the accompanying drawings and specific implementation examples. The hardware system structure of the air compressor control optimization system is as attached figure 1 shown. Select a set of control system to form all the hardware equipment needed. The configuration of this system structure is because the number of air compressor equipment in the factory is generally large, and the air compressors are generally scattered in multiple workshops, but it is also applicable to the situation where they are concentrated in one workshop. In this system structure, an air compressor workshop is defined as a field area. The functions and functions of each hardware in the system structure are described as follows.

[0070] The present invention proposes an integrated modular group control air compressor optimization system, such as figure 1 As shown, including: control management equipment, main control equipment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com