Fabricated fireproof and anti-explosion composite plate

A composite board and prefabricated technology, used in fire protection, walls, buildings, etc., can solve the problems of complicated production and installation steps, inability to cut, rupture of explosion-proof panels, etc., to achieve convenient and fast installation and disassembly, and reduce irreparable damage. Loss, reduce the effect of cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

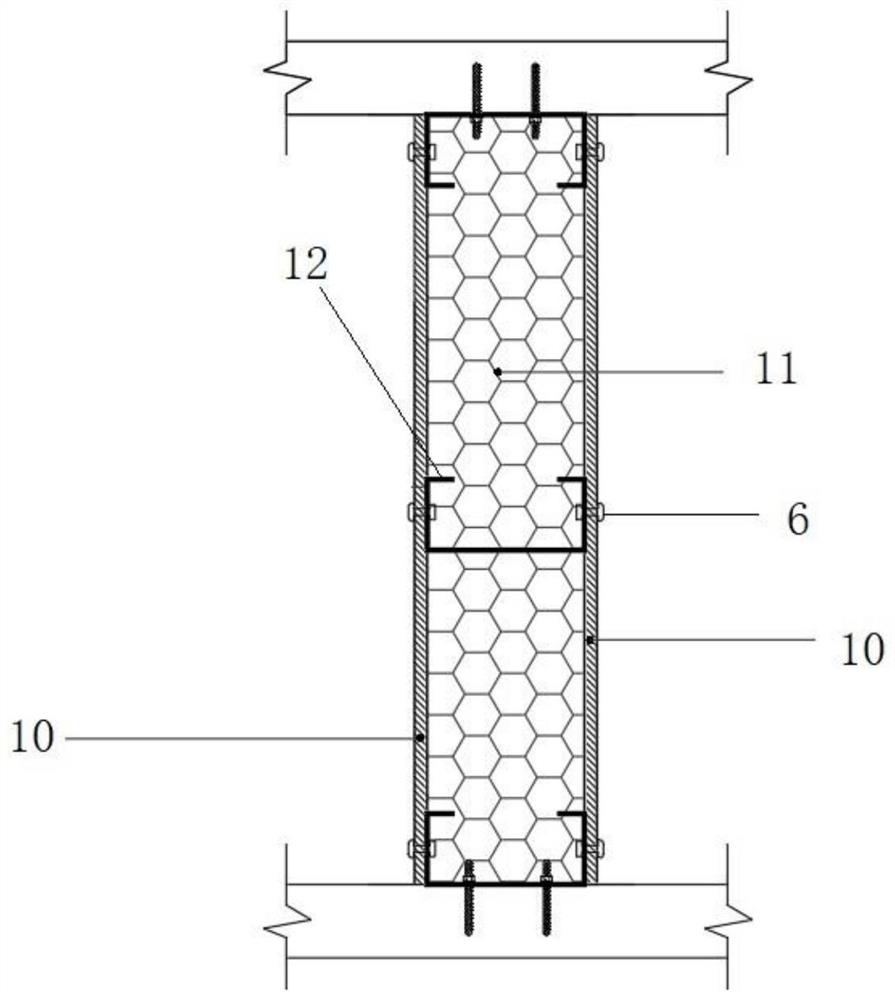

[0036] figure 1A schematic diagram of an embodiment of an assembled fireproof and explosion-resistant composite panel provided by the present invention, including a first metal plate 1 and a second metal plate 3, and a fireproof board 2 is included between the first metal plate 1 and the second metal plate 3, Pre-drilled holes are set on the first metal plate 1, the second metal plate 3 and the fireproof board 2, and the reinforcing connector 4 passes through the first metal plate 1, the second metal plate 3 and the fireproof board 2 through the pre-drilled holes, and strengthens the connection and fixing parts 4 Fix the above three; the first metal plate and the second metal plate are preferably galvanized steel plates or color-coated plates, but not limited to the above two, the fireproof board is preferably cement fiber board 2, and the reinforced and fixed connectors are preferably made of female and female rivets 4 .

[0037] The prefabricated fireproof and explosion-pro...

Embodiment 2

[0046] Figure 5 The middle is a schematic diagram of another embodiment of the assembled fireproof and anti-explosion panel provided by the present invention. The difference between the second embodiment and the first embodiment is only the gasket 5. Spacers 5 are included between the zinc steel plates 1 .

[0047] Compared with the prior art, the present invention adopts mother-in-female rivets to realize assembly fixation instead of welding and steel plate stamping fixation in the prior art, which has at least the following advantages:

[0048] First, the present invention fixes by rivets, which can be typesetting and prefabricated according to the area required on site, effectively utilizing materials, and at the same time adopts a method of avoiding stamping so that the surface of the assembled fireproof and explosion-resistant composite board does not exist due to stamping. Potholes, to ensure the smooth and beautiful surface of the assembled fireproof and explosion-res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com