A kind of priming agent for aerobic fermentation of cow dung and preparation method thereof

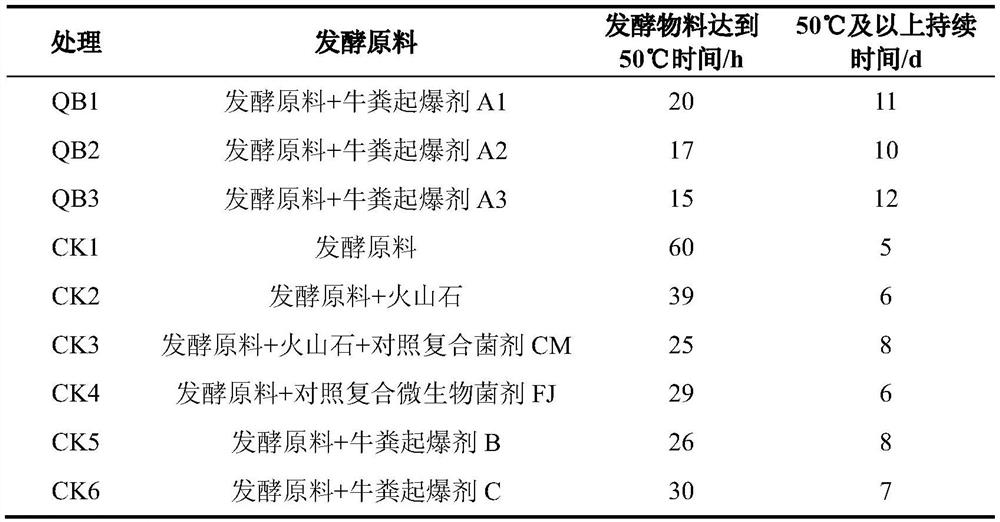

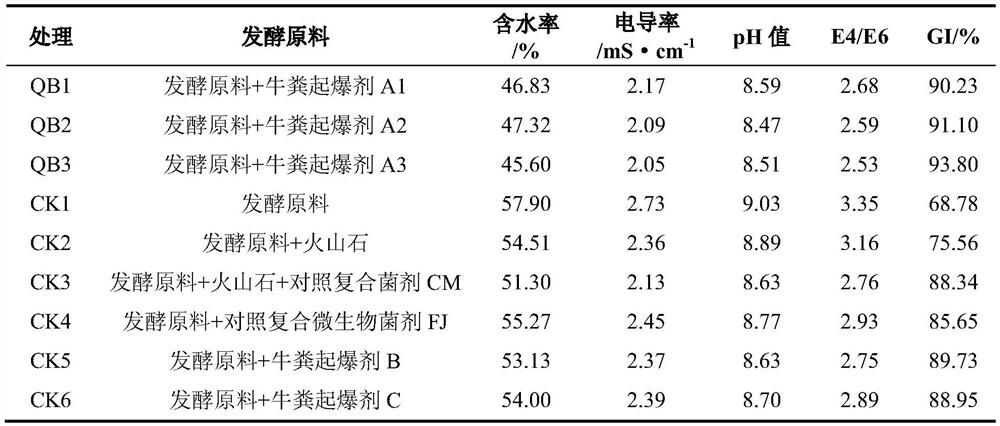

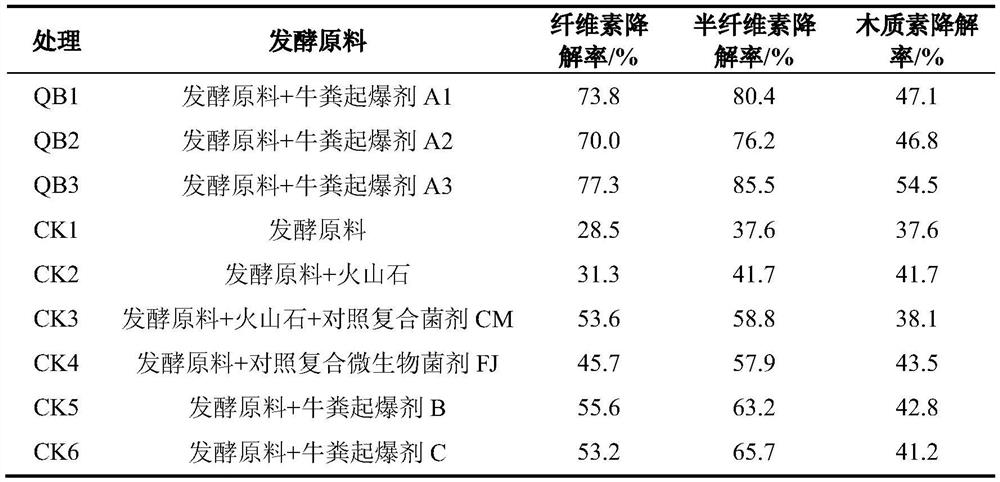

An aerobic fermentation and priming agent technology, which is applied in the field of agricultural and rural waste recycling, can solve the problems of shortening the heating time of priming agents, less priming agents, and large differences, so as to improve the quality of aerobic fermentation products, shorten the fermentation cycle, The effect of prolonging the high temperature period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Mix Streptomyces xylophilus, Bacillus subtilis, Lactobacillus, Clostridium sporogenes, Thermomonospora, and Vibrio cellulosus according to the ratio of 25:15:5:20:17:18, and add them to the microbial culture Base (prepared by adding 5 g of beef extract, 15 g of peptone, and 5 g of sodium chloride to each 1 L of water, and sterilizing at 121°C for 25 minutes), cultured at 25°C for 30 hours, to obtain a composite microbial agent;

[0046] (2) Mix the volcanic rock, glucose and microbial culture medium uniformly at a ratio of 15g: 10ml: 70ml to obtain a high-efficiency immobilization medium.

[0047] (3) Take 1g of compound microbial agent and place it in a 250ml Erlenmeyer flask, add 10ml of high-efficiency immobilization medium to ensure that each gram contains 5×10 beneficial bacteria 8 Above, adsorb and fix in a 150rpm shaker at 25°C for 30h, centrifuge at 2000r / min for 15min, pour off the supernatant, and freeze-dry the lower layer to become the cow dung aerobic f...

Embodiment 2

[0049] (1) Mix Streptomyces xylophilus, Bacillus subtilis, Lactobacillus, Clostridium sporogenes, Thermomonospora, and Vibrio cellulosus according to the ratio of 27:15:5:18:20:15, and add them to the microbial culture (prepared by adding 5 g of beef extract, 15 g of peptone, and 5 g of sodium chloride to each 1 L of water, and sterilizing at 121° C. for 25 minutes), and cultured at 25° C. for 28 hours to obtain a composite microbial agent.

[0050] (2) Mix the volcanic rock, glucose and microbial culture medium uniformly in the ratio of 18g: 10ml: 70ml to obtain a high-efficiency immobilization medium.

[0051] (3) Take 1g of compound microbial agent and place it in a 250ml Erlenmeyer flask, add 8ml of high-efficiency immobilization medium to ensure that each gram contains 5×10 beneficial bacteria 8 Above, fix in 150rpm shaker at 25°C for 30h, centrifuge at 2000r / min for 25min, pour off the supernatant, and freeze-dry the lower layer to become cow dung aerobic fermentation pr...

Embodiment 3

[0053] (1) Mix Streptomyces xylophilus, Bacillus subtilis, Lactobacillus, Clostridium sporogenes, Thermomonospora, and Vibrio cellulosus according to the ratio of 25:15:5:20:25:10, and add them to the microbial culture (prepared by adding 5 g of beef extract, 15 g of peptone, and 5 g of sodium chloride to each 1 L of water, and sterilizing at 121° C. for 25 minutes), and cultured at 25° C. for 28 hours to obtain a composite microbial agent.

[0054] (2) Mix the volcanic rock, glucose and microbial culture medium uniformly in the ratio of 20g: 10ml: 75ml to obtain a high-efficiency immobilization medium.

[0055] (3) Take 1g of compound microbial agent and place it in a 250ml Erlenmeyer flask, add 6ml of high-efficiency immobilization medium to ensure that each gram contains 5×10 beneficial bacteria 8 As above, adsorb and fix in a 150rpm shaker at 25°C for 32h, centrifuge at 4000r / min for 15min, discard the supernatant, and freeze-dry the lower layer to become the priming agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com