Locking Mechanisms, Booms and Cranes

A technology of locking mechanism and lifting arm, which is applied in the direction of cranes, etc., can solve the problems that the locking mechanism cannot stably lock and unlock the jib, and the transmission process is unstable and out of joint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

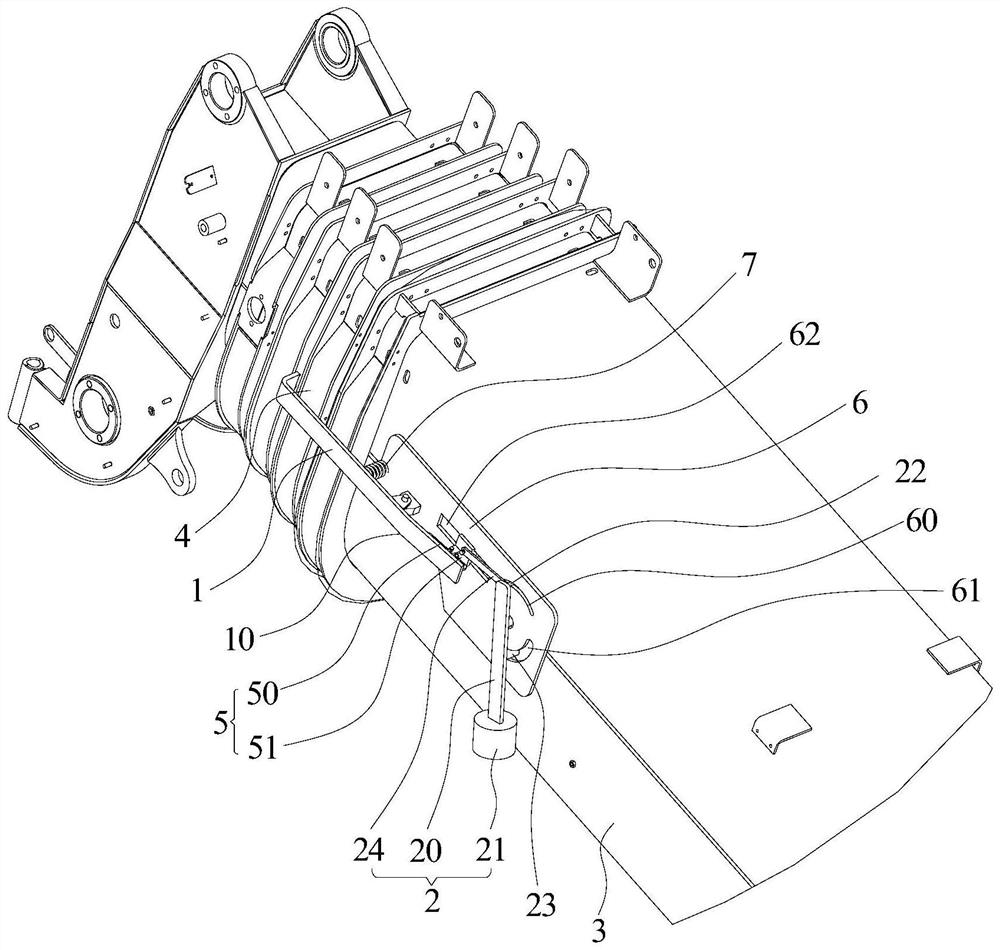

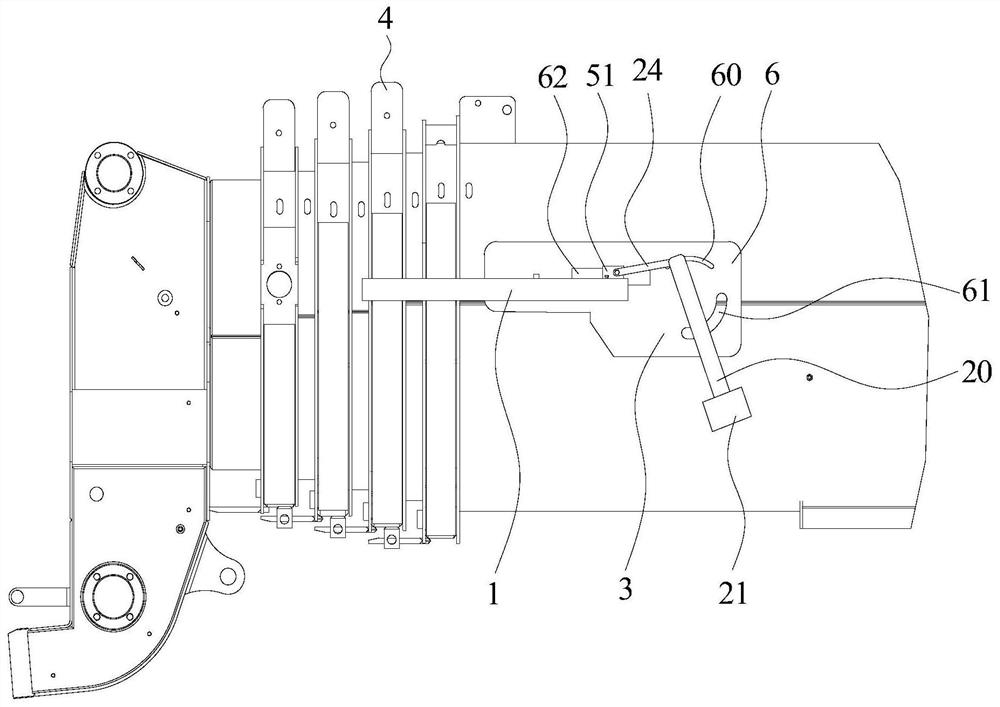

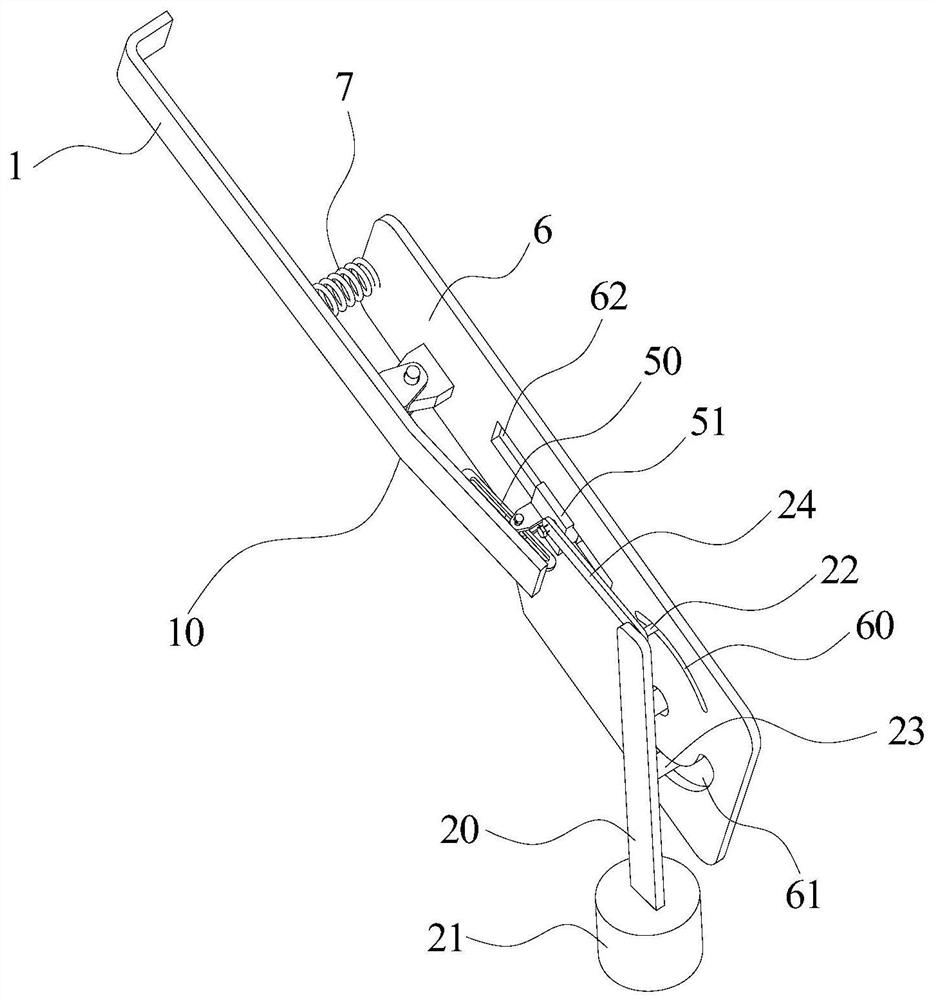

[0037] Such as Figure 1-Figure 3 As shown, the locking mechanism provided in this embodiment includes a locking lever 1 and a power assembly 2 . Such as figure 1 with figure 2 As shown, the position between the two ends of the locking rod 1 is hinged on the basic arm 3 of the boom, one end of the locking rod 1 is located on one side of the jib 4 of the boom, and the other end of the locking rod 1 is connected to the The output ends of the power components 2 are connected through a sliding pair 5 . Such as figure 1 with image 3 As shown, the sliding pair 5 and the power assembly 2 are installed on the basic arm 3 of the boom, and the power assembly 2 is used to drive the sliding pair 5 to slide in a direction inclined to the basic arm 3 of the boom to drive the locking lever 1 One end connected with the sliding pair 5 is close to or far away from the basic arm 3 of the boom. In this embodiment, the jib may be a jib on a truck crane. Further, the boom may include a bas...

Embodiment 2

[0086] The jib provided in this embodiment includes a basic arm, an auxiliary arm and the locking mechanism in the first embodiment. The auxiliary arm is slidingly connected with the basic arm, and the locking mechanism is installed between the basic arm and the auxiliary arm.

[0087] The boom provided in this embodiment includes the locking mechanism in Embodiment 1, so the boom provided in this embodiment and the locking mechanism in Embodiment 1 can solve the same technical problem and achieve the same technical effect.

[0088] The boom provided by this embodiment also alleviates the separation structure between the power assembly and the working rod in the locking mechanism adopted on the boom of the truck crane existing in the prior art, so the power assembly in the locking mechanism and the working rod are separated. The transmission process between the working rods is not stable, and it is prone to disconnection, which leads to the technical problem that the locking m...

Embodiment 3

[0090] The crane provided in this embodiment includes the boom in Embodiment 2, so the crane provided in this embodiment and the boom in Embodiment 1 can solve the same technical problem and achieve the same technical effect.

[0091] The crane provided by this embodiment also alleviates the separation structure between the power assembly and the working rod in the locking mechanism adopted on the boom of the truck crane existing in the prior art, so the power assembly and the working rod in the locking mechanism The transmission process between them is not stable, and it is prone to disconnection, which leads to the technical problem that the locking mechanism cannot stably lock the auxiliary arm and unlock the auxiliary arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com