Series-parallel connection mixed oil way system for unmanned aerial vehicle

An oil circuit system and UAV technology, applied to the fuel tank of the power unit, etc., can solve problems that affect the flight safety of UAVs, engine flameout, etc., and achieve the effects of low cost, convenient operation, and simple management and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

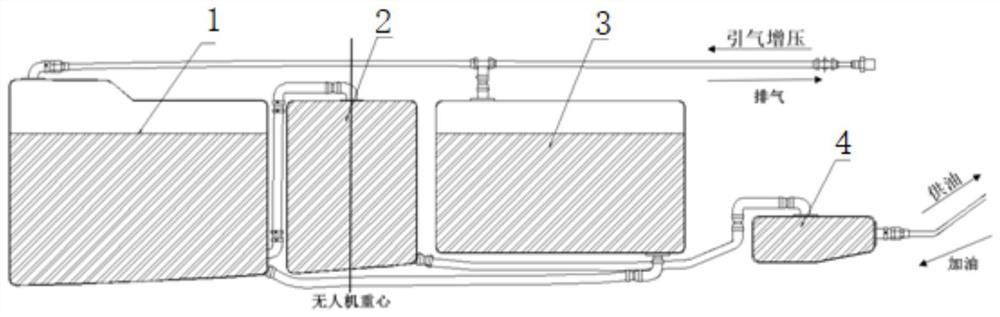

[0011] combine figure 1 , a series-parallel hybrid oil circuit system for unmanned aerial vehicles of the present invention, comprising a first fuel tank 1, a second fuel tank 2, a third fuel tank 3 and a consumption fuel tank 4 arranged in sequence;

[0012] The middle position of the second fuel tank 2 is located at the center of gravity of the drone; the tops of the first fuel tank 1 and the third fuel tank 3 are connected to air pipes at the same time, and serve as exhaust ports and bleed air booster ports; the bottom of the first fuel tank 1 The bottom of the first oil tank 1 is communicated with the top of the second oil tank 2 through the pipeline; the bottom of the second oil tank 2 is communicated with the top of the consumption oil tank 4 through the pipeline; that is, the first oil tank After 1 is connected in parallel with the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com