A kind of magnesium-doped cobalt disulfide composite carbon nanotube material, preparation method and application

A technology of cobalt disulfide and carbon nanotubes, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., to achieve uniform particle size and element distribution, high stability and cycle performance, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a magnesium-doped cobalt disulfide composite carbon nanotube material ((Co, Mg)S with bifunctional activity 2 @CNTs) preparation methods such as figure 1 As shown, the specific preparation steps are as follows:

[0044] Step 1: 0.498g Co(Ac) 2 4H 2 O and 0.256g Mg(NO 3 ) 2 ·6H 2 O was added to 35 mL of deionized water, stirred until the crystals disappeared, and then transferred to an ultrasonic machine for sonication to ensure complete dissolution.

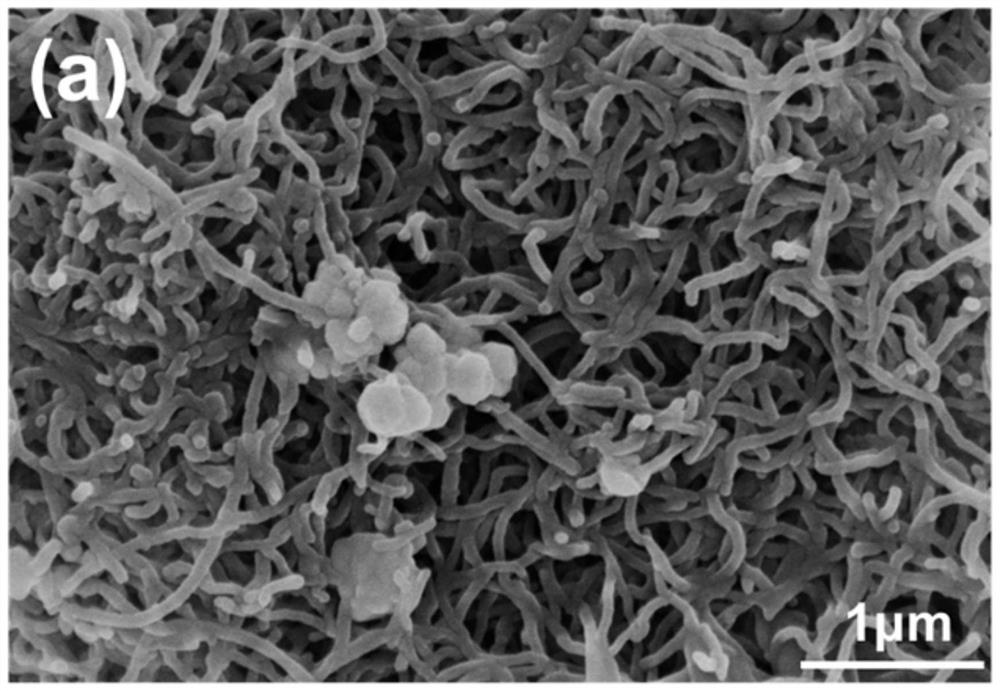

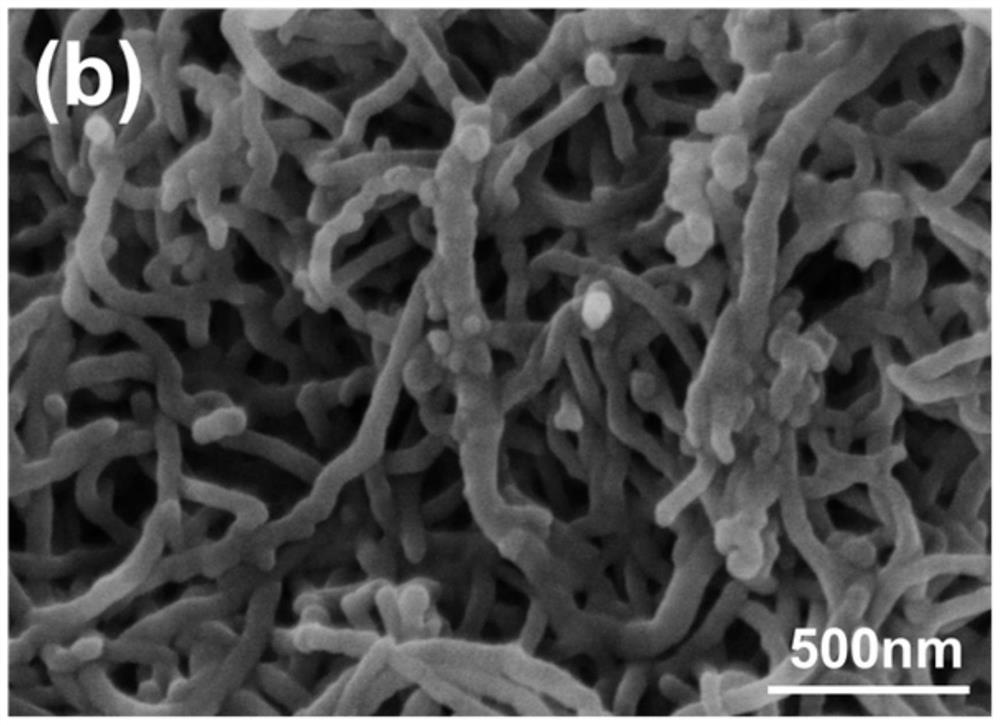

[0045] Step 2: Add 50mg of carbon nanotubes (particle size: 20-30nm, purity>98wt%, Zhongke Times Nano Center) into the above solution, and stir ultrasonically for 30 minutes to obtain a mixed solution.

[0046] Step 3: Transfer the mixed solution to a stirrer, add 0.64g of sulfur powder and 5mL of ethanol (as a dispersant) under magnetic stirring.

[0047] Step 4: After ultrasonically oscillating the mixture for 45 minutes, transfer it to a polytetrafluoroethylene lining, add it to the react...

Embodiment 2

[0051] This embodiment provides a magnesium-doped cobalt disulfide composite carbon nanotube material ((Co, Mg)S with bifunctional activity 2 @CNTs) preparation methods such as figure 1 As shown, the specific preparation steps are as follows:

[0052] Step 1: 0.498g Co(Ac) 2 4H 2 O and 0.256g Mg(NO 3 ) 2 ·6H 2 O was added to 35 mL of deionized water, stirred until the crystals disappeared, and then transferred to an ultrasonic machine for sonication to ensure complete dissolution.

[0053] Step 2: Add 50mg of carbon nanotubes (particle size: 20-30nm, purity>98wt%, Zhongke Times Nano Center) into the above solution, and stir ultrasonically for 30 minutes to obtain a mixed solution.

[0054] Step 3: Transfer the mixed solution to a stirrer, add 0.64g of sulfur powder and 5mL of ethanol (as a dispersant) under magnetic stirring.

[0055] Step 4: After ultrasonically oscillating the mixture for 45 minutes, transfer it to a polytetrafluoroethylene lining, add it to the react...

Embodiment 3

[0059] This embodiment provides a magnesium-doped cobalt disulfide composite carbon nanotube material ((Co, Mg)S with bifunctional activity 2 @CNTs) preparation methods such as figure 1 As shown, the specific preparation steps are as follows:

[0060] Step 1: 0.498g Co(Ac) 2 4H 2 O and 0.256g Mg(NO 3 ) 2 ·6H 2 O was added to 40 mL of deionized water, stirred until the crystals disappeared, and then transferred to an ultrasonic machine for sonication to ensure complete dissolution.

[0061] Step 2: Add 50mg of carbon nanotubes (particle size: 20-30nm, purity>98wt%, Zhongke Times Nano Center) into the above solution, and stir ultrasonically for 30 minutes to obtain a mixed solution.

[0062] Step 3: Transfer the mixed solution to a stirrer, add 0.64g of sulfur powder and 5mL of ethanol (as a dispersant) under magnetic stirring.

[0063] Step 4: After ultrasonically oscillating the mixture for 45 minutes, transfer it to a polytetrafluoroethylene lining, add it to the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com