Gas-liquid heat transfer device based on ceramic matrix composite resin filler and filler preparation method

A ceramic matrix composite, ceramic slurry technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of decomposition, slag removal, poor corrosion resistance, etc. Elongation and strength, improved corrosion resistance, improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

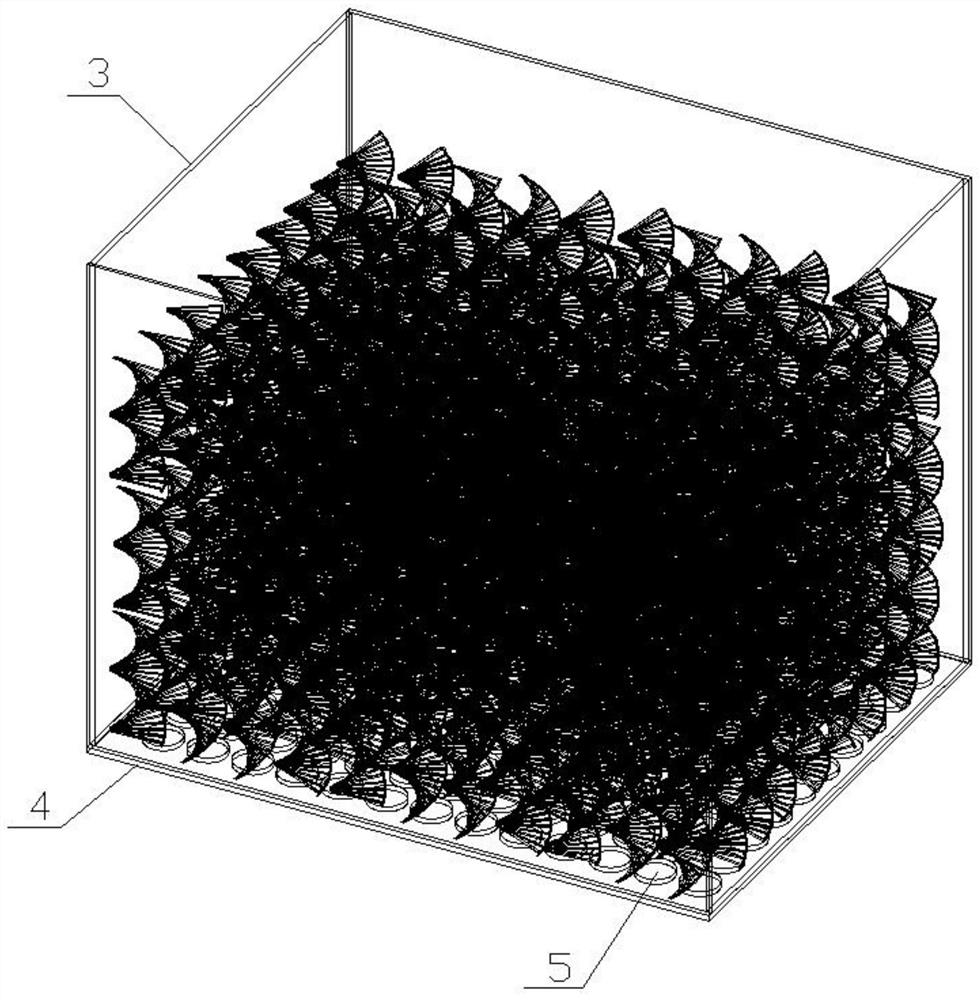

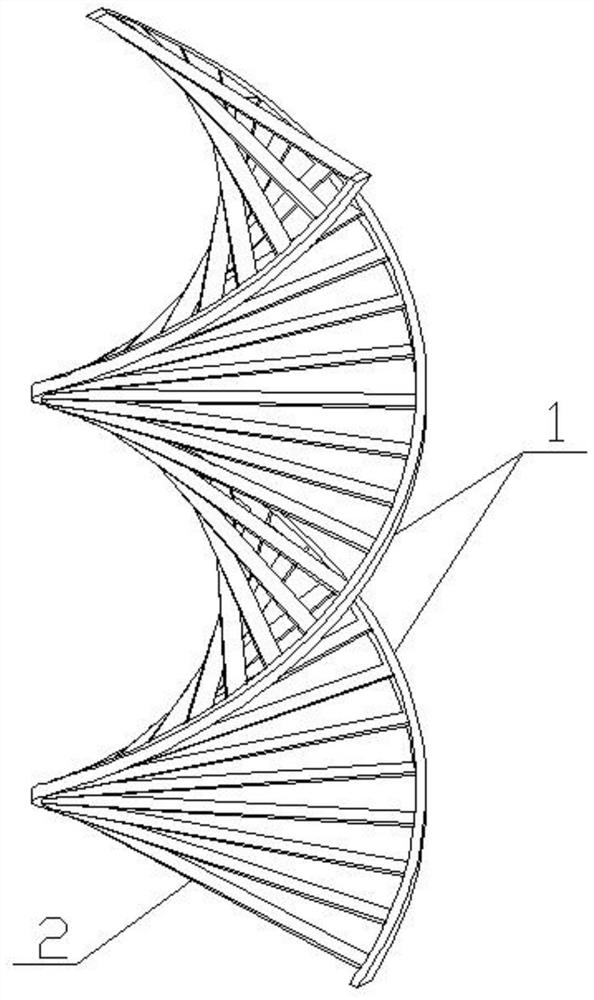

[0034] like Figure 1-2 As shown, a gas-liquid heat transfer device based on a ceramic matrix composite resin filler, the filler includes two frames 1 intertwined in a helical structure, a number of thin slices 2, the thin slices 2 are quadrangular, and the thickness of the thin slices 2 is 0.3-0.8mm. The frames 1 are connected by several sheets 2, and the frames 1 and the sheets 2 are all made of ceramic matrix composite resin.

[0035] The filler has a rough surface, and the filler is filled in the ventilation duct 3 , the top of which is open, and the bottom of the ventilation duct 3 is fixed with a support orifice plate 4 , and a plurality of ventilation holes 5 are opened on the support orifice plate 4 .

[0036] A filling preparation method for a gas-liquid heat transfer device based on a ceramic matrix composite resin filler, comprising the following steps:

[0037] (1) In parts by weight, select 50-60 parts of ceramic slurry and 20-30 parts of resin fiber, and stir th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com