Mixed matrix membrane with high-selectivity gas channel and preparation method

A technology of mixed matrix membranes and gas channels, applied in the field of membrane separation, can solve the problems of low permeability and selectivity of gas separation membranes, the influence of interfacial compatibility on MMMs gas permeation selectivity, interfacial compatibility problems, etc., and achieve good Effects of permeability and selectivity, high selectivity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A mixed matrix membrane with highly selective gas channels is prepared by a method comprising the following steps:

[0065] (1) Coating polydimethylsiloxane (PDMS) and polyvinyl alcohol (PVA) on the surface of polysulfone to prepare a hydrophilic modified polysulfone membrane, the specific steps are as follows:

[0066] First, use n-heptane to prepare PDMS into a PDMS n-heptane solution with a concentration of 0.4wt%, and then use a scraper to coat the PDMS n-heptane solution with a concentration of 0.4wt% on the surface of the PSf film with a coating thickness of 0.08 μm, and then controlled the temperature at 60°C and 40% RH to dry for 18 hours to obtain a PDMS-coated PSf film; then soak the PDMS-coated PSf film with an aqueous solution of 0.25wt% PVA for 1 hour, and then Continue to dry for 8 hours under the conditions of controlling the temperature at 30°C and 40% RH to obtain a hydrophilic modified polysulfone membrane, hereinafter referred to as MPSf membrane;

[0...

Embodiment 2

[0078] A mixed matrix membrane with highly selective gas channels is prepared by a method comprising the following steps:

[0079] (1), polydimethylsiloxane (PDMS) and polyvinyl alcohol (PVA) are coated on the surface of polysulfone to prepare hydrophilic modified polysulfone membrane, and concrete steps are with the step of embodiment 1 (1) ), obtain a hydrophilic modified polysulfone membrane, i.e. MPSf membrane;

[0080] (2), adopt low-temperature solid-phase synthesis method, utilize metal salt and ligand to synthesize metal composite hydrophobic filler particle in situ on the surface of the MPSf membrane of step (1) gained, described metal salt is anhydrous copper acetate, just Described ligand is 4-chlorobenzoic acid, and other is with the step (2) of embodiment 1, obtains hydrophobic HMP (Cl) / MPSf film;

[0081] The contact angle of the surface of the hydrophobic HMP(Cl) / MPSf film obtained above is determined to be 140°-145°;

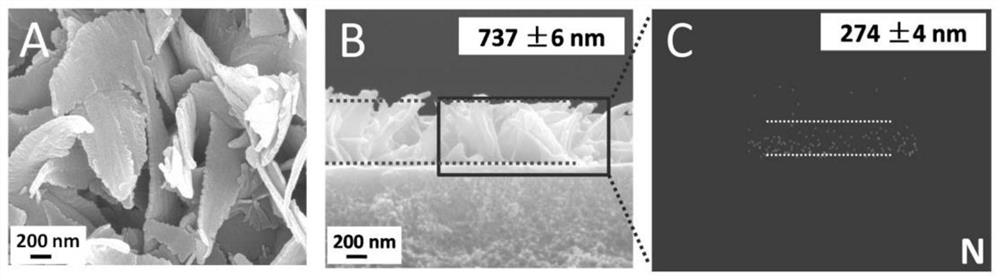

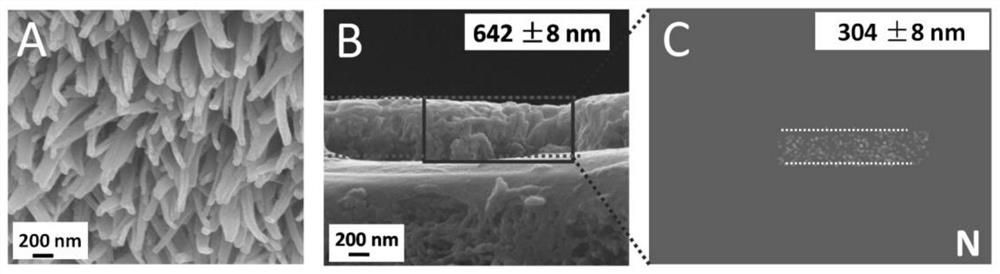

[0082] Using a scanning electron microsc...

Embodiment 3

[0088] A mixed matrix membrane with highly selective gas channels is prepared by a method comprising the following steps:

[0089] (1), polydimethylsiloxane (PDMS) and polyvinyl alcohol (PVA) are coated on the surface of polysulfone to prepare hydrophilic modified polysulfone membrane, and concrete steps are with the step of embodiment 1 (1 ), obtain a hydrophilic modified polysulfone membrane, i.e. MPSf membrane;

[0090] (2), adopt low-temperature solid-phase synthesis method, utilize metal salt and ligand to synthesize metal composite hydrophobic filler particle in situ on the surface of the MPSf membrane of step (1) gained, described metal salt is anhydrous copper acetate, just Described ligand is 4-bromobenzoic acid, and other is with the step (2) of embodiment 1, obtains hydrophobic HMP (Br) / MPSf film;

[0091] The contact angle of the hydrophobic HMP(Br) / MPSf film surface of the above-mentioned gained is measured as 143°-147°;

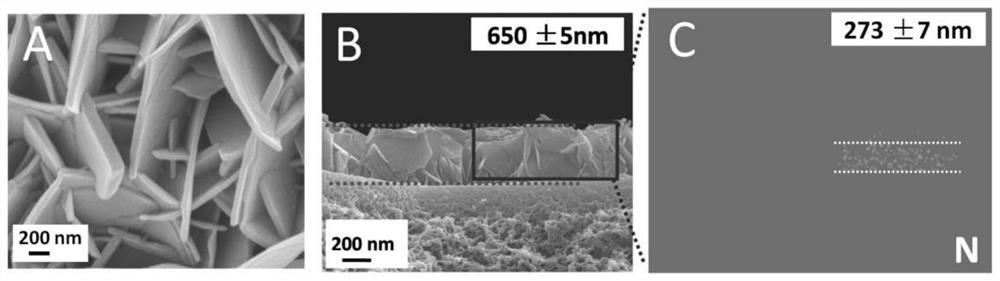

[0092] Using a scanning electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com