Electrophotographic photoreceptor, manufacturing method therefor, and electrophotographic device

An electrophotographic and photoreceptor technology, which is applied in the electrical recording process using charge patterns, the equipment and optics of the electrical recording process applying charge patterns, etc. Excellent solvent and crack resistance, excellent sensitivity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

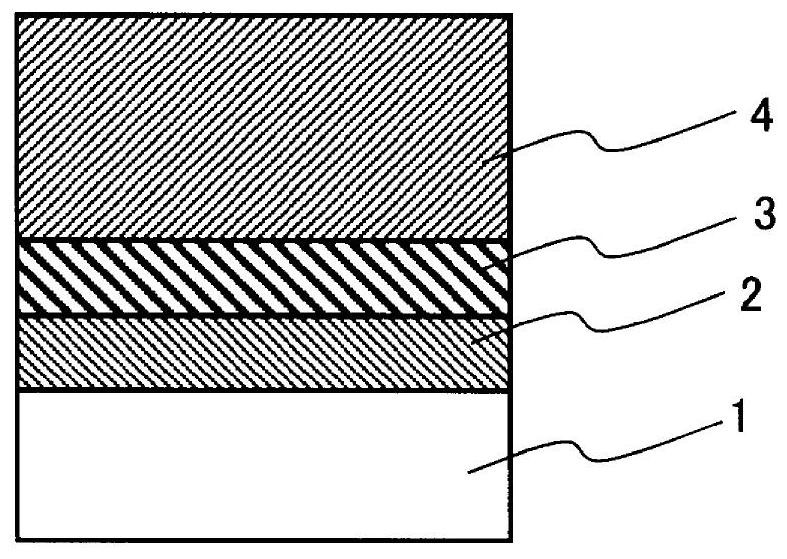

[0098] 15 parts by mass of p-vinylphenol resin (trade name Malkarinka MH-2: manufactured by Maruzen Petrochemical Co., Ltd.) and 10 parts by mass of N-butylated melamine resin (trade name Yuban 2021: manufactured by Mitsui Chemicals Co., Ltd.) were carried out. 75 parts by mass of the aminosilane-treated titanium oxide fine particles are respectively dissolved or dispersed in a methanol / butanol mixed solvent of 750 parts by mass / 150 parts by mass to prepare a coating solution for forming an intermediate layer. A conductive substrate made of an aluminum alloy having an outer diameter of 30 mm and a length of 255 mm was immersed in the obtained coating solution for the intermediate layer, and then lifted up to form a coating film on the outer periphery. The substrate was dried at a temperature of 140°C for 30 minutes to form an intermediate layer with a film thickness of 3 μm.

[0099] Next, using a sand mixing and dispersing machine, 15 parts by mass of Y-type oxytitanium phthaloc...

Embodiment 2~4、6、7

[0104] [Examples 2 to 4, 6, 7, and Comparative Examples 1 to 4]

[0105] The negatively charged laminated electrophotographic sensitization was carried out by the same method as in Example 1, except that the type and the amount of the binder resin and the hole transport material of the charge transport layer in Example 1 were changed as shown in Table 1 below. Body preparation.

[0106] The materials used are as follows.

[0107]

[0108] [Viscosity average molecular weight: 50,500]

[0109]

[0110] [Viscosity average molecular weight: 52,500]

[0111]

Embodiment 5

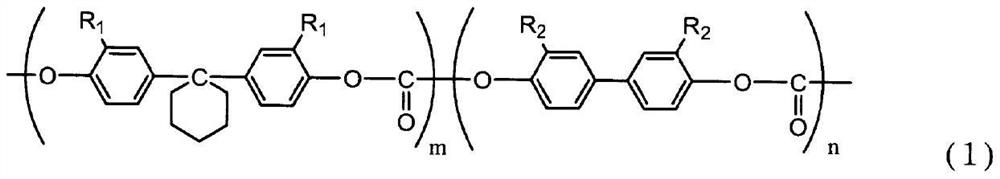

[0113] Except that the binder resin of the charge transport layer in Example 1 is changed to the above structural formula (B-1), n / (m+n)=0.6, and the chain terminal group has the following structural formula (4)

[0114]

[0115] A negatively charged laminated electrophotographic photoreceptor was prepared by the same method as in Example 1, except for the copolymer polycarbonate resin having a viscosity average molecular weight of 49,500 with the structure shown.

[0116] [Table 1]

[0117]

[0118] Using the photoreceptors prepared in Examples 1 to 7 and Comparative Examples 1 to 4, the sensitivity characteristics and solvent resistance (the amount of elution of the hole transporting substance and the presence or absence of cracks) were evaluated by the following evaluation methods, respectively.

[0119] [Sensitivity characteristic evaluation]

[0120] For the obtained photoreceptor, using an electrical characteristic tester (CYNTHIA, manufactured by Gentec), the sensitivity characte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com