Preparation method of wave absorbing body, wave absorbing body and application of wave absorbing body

A wave-absorbing body and wave-absorbing agent technology, applied in the field of wave-absorbing materials, can solve problems such as difficult to achieve industrialization, time-consuming, labor-intensive, and large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

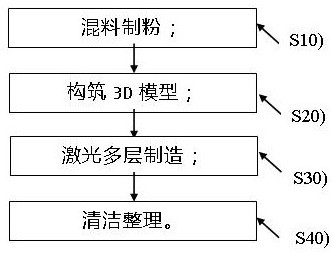

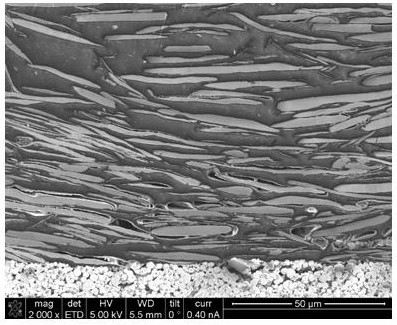

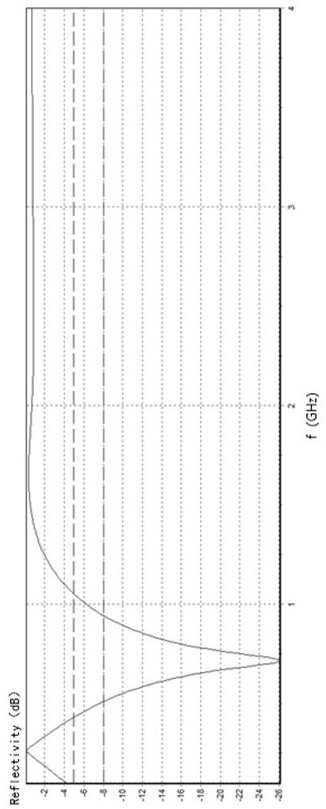

[0028] The embodiment of the present invention discloses a method for preparing a wave absorber. The raw material of the wave absorber includes uniformly mixed wave absorber powder and thermoplastic polymer, and the pre-created three-dimensional figure of the wave absorber is used as the molding target. The wave absorber The three-dimensional figure is decomposed into a multi-layer two-dimensional structure of the target thickness; the raw material of the absorber is heated and melted by the rapid prototyping equipment, and a magnetic field whose magnetic force line is parallel to the two-dimensional structure is applied at the same time, so that the thermoplastic polymer melts and absorbs The wave agent powder is bonded and coated, and the bonded and coated wave absorber powder is arranged in parallel under the action of a magnetic field to form a wave absorber with a three-dimensional structure.

[0029] The embodiment of the invention also discloses a wave absorber, which is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com